The medical device industry is undergoing a period of rapid innovation, driven by advancements in minimally invasive surgery, diagnostic imaging, and patient monitoring. Central to many of these advancements are gear motors – compact, efficient power sources that enable precise and reliable movement in a wide array of medical applications. However, the increasing complexity of these devices and the stringent regulatory environment are driving a renewed focus on performance optimization, specifically concerning the “English” performance – a crucial metric encompassing speed, torque, efficiency, and especially, noise and vibration characteristics. This article will explore the reasons behind this trend, the challenges involved, and the potential benefits for medical equipment manufacturers. Furthermore, it will highlight how companies like MES-Drive are playing a pivotal role in addressing these evolving needs.

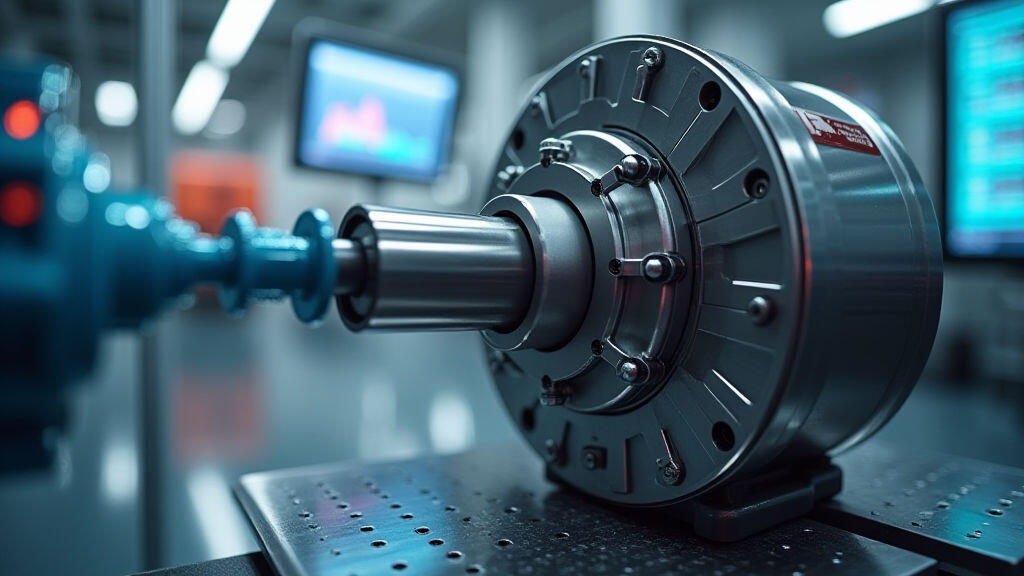

Modern medical equipment demands unparalleled precision. Think of robotic surgical systems requiring movements measured in micrometers, or infusion pumps needing to deliver medication with utmost accuracy. These applications demand gear motors capable of delivering consistent power output with minimal deviation. Reliability is equally paramount. Failure of a component within a medical device can have serious, even life-threatening, consequences. Therefore, manufacturers are prioritizing components that boast long lifespans and exceptional performance under demanding conditions.

The rise of personalized medicine is also contributing to this trend. As treatments become more tailored to individual patients, devices need to be adaptable and capable of responding to fluctuating needs. This puts further strain on components like gear motors, demanding more sophisticated designs and optimized performance characteristics. The confluence of these factors – precision, reliability, and adaptability – is creating a significant demand for higher-performing gear motors.

The term "English performance," while not a universally standardized term within the industry, refers to a holistic evaluation of a gear motor's operational characteristics, with an emphasis on qualities that directly impact patient safety and clinical effectiveness. It goes beyond simple power ratings and includes:

Achieving optimal "English" performance isn't straightforward. Several challenges complicate the process:

Companies like MES-Drive are proactively addressing these challenges through innovation in gear motor design and manufacturing. They are focusing on several key areas:

MES-Drive's commitment to quality and performance has positioned them as a trusted supplier to leading medical device manufacturers. They are actively collaborating with OEMs to develop innovative gear motor solutions for a wide range of medical applications. Their expertise in materials science and precision engineering allows them to deliver gear motors that not only meet but exceed the stringent requirements of the medical device industry.

The future of gear motors in medical equipment is inextricably linked to advancements in artificial intelligence (AI) and data analytics. AI algorithms can be used to analyze data from IoT sensors to identify potential performance issues before they occur, optimize gear motor designs, and improve manufacturing processes.

For example, machine learning can analyze historical performance data to predict bearing failures or identify areas where noise levels can be reduced. This allows manufacturers to proactively address potential problems and ensure the long-term reliability of their devices. Furthermore, AI can assist in the design optimization process, identifying optimal gear ratios and material choices for specific applications.

The increasing emphasis on data-driven optimization, coupled with the growing demand for precision and reliability, is paving the way for a new generation of gear motors that will enable even more sophisticated and life-saving medical devices.

The medical device industry’s increasing focus on the "English" performance of gear motors is a direct consequence of the growing demand for precision, reliability, and adaptability in modern healthcare. Stringent regulatory requirements, miniaturization trends, and the rise of personalized medicine are all driving this trend. Companies like MES-Drive are leading the charge, developing innovative gear motor solutions that meet the evolving needs of medical device manufacturers. With the integration of AI and data analytics, the future of gear motors in medicine promises to be even more exciting, leading to the development of more sophisticated, efficient, and life-saving devices. The ability to optimize performance, reduce noise, and enhance reliability within these components is not just a technical challenge; it’s a critical factor in advancing patient care and improving healthcare outcomes.

Leave A Reply

Your email address will not be published. Required fiels are marked