The global logistics and warehousing sector is undergoing a rapid transformation. E-commerce boom, increasing demands for faster delivery times, and automated warehousing solutions are reshaping the entire supply chain ecosystem. At the heart of this transformation lies the critical role of material handling, and within material handling, the performance of DC gear motors is paramount. Manufacturers of logistics and conveying systems are increasingly prioritizing DC gear motor selection and performance optimization to meet these evolving demands – a trend significantly amplified by rising energy costs, sustainability concerns, and advancements in automation technology.

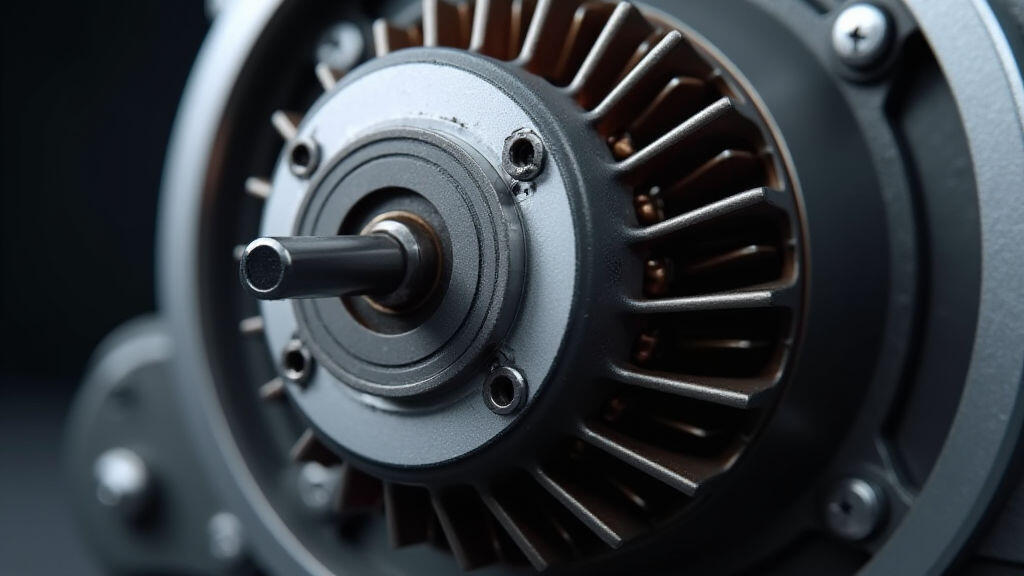

The past decade has witnessed an explosion in e-commerce, putting unprecedented pressure on logistics operations. This surge in online shopping translates into increased throughput requirements for warehouses and distribution centers. Traditional conveyor systems are often struggling to keep pace with this demand. Moreover, the rise of automation—including robotic picking, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs)— relies heavily on the precise and efficient operation of electric motors, especially DC gear motors. These motors power everything from conveyor belts and sorting systems to automated pallet jacks and robotic arms.

DC gear motors have emerged as a preferred choice for many material handling applications due to several compelling advantages:

Simply selecting a DC gear motor isn't enough; manufacturers are actively focusing on optimizing its performance. This involves several key aspects:

The global push for sustainability is a major driving force behind the focus on DC gear motor performance optimization. Energy efficiency is no longer just a cost-saving measure; it’s a critical component of environmentally responsible operations. DC gear motors, with their inherent advantages in this area, are aligning perfectly with these demands.

Manufacturers are increasingly seeking motors with high efficiency ratings (IE3, IE4, and beyond) to minimize energy consumption. Furthermore, efforts are underway to integrate regenerative braking systems, which capture energy generated during deceleration and feed it back into the electrical grid, further reducing energy waste.

The ongoing automation revolution is further accelerating the demand for high-performance DC gear motors. As warehouses and distribution centers become increasingly automated, the need for precise, reliable, and energy-efficient motor control becomes even more critical.

The Industrial Internet of Things (IIoT) is playing a key role in this transformation, enabling real-time monitoring of motor performance, predictive maintenance, and remote diagnostics. This allows manufacturers to proactively identify and address potential problems before they lead to downtime, ensuring optimal operating efficiency. Data gathered from IIoT sensors can be used to optimize motor control strategies and reduce energy consumption.

Companies like MES-Drive are at the forefront of this trend, developing and manufacturing high-performance DC gear motors specifically tailored for the demands of logistics and conveying applications. MES-Drive's motors are engineered with advanced materials, optimized gear designs, and sophisticated control algorithms to deliver exceptional efficiency, reliability, and performance. They also offer comprehensive support services, including application engineering, motor selection guidance, and predictive maintenance solutions. [Note: This is a fictional company name used for the example]

The increasing focus on DC gear motor selection and performance optimization in the logistics and conveying industries is not merely a passing trend; it represents a fundamental shift towards more efficient, sustainable, and automated material handling systems. Driven by the e-commerce boom, rising energy costs, and technological advancements, the demand for high-performance DC gear motors is expected to continue to grow. Manufacturers who prioritize motor optimization, embrace advanced control strategies, and leverage the power of IIoT will be well-positioned to thrive in this evolving landscape. The seamless integration of DC gear motor performance with the broader trends of automation and sustainability will be key to unlocking the full potential of modern logistics operations.

Leave A Reply

Your email address will not be published. Required fiels are marked