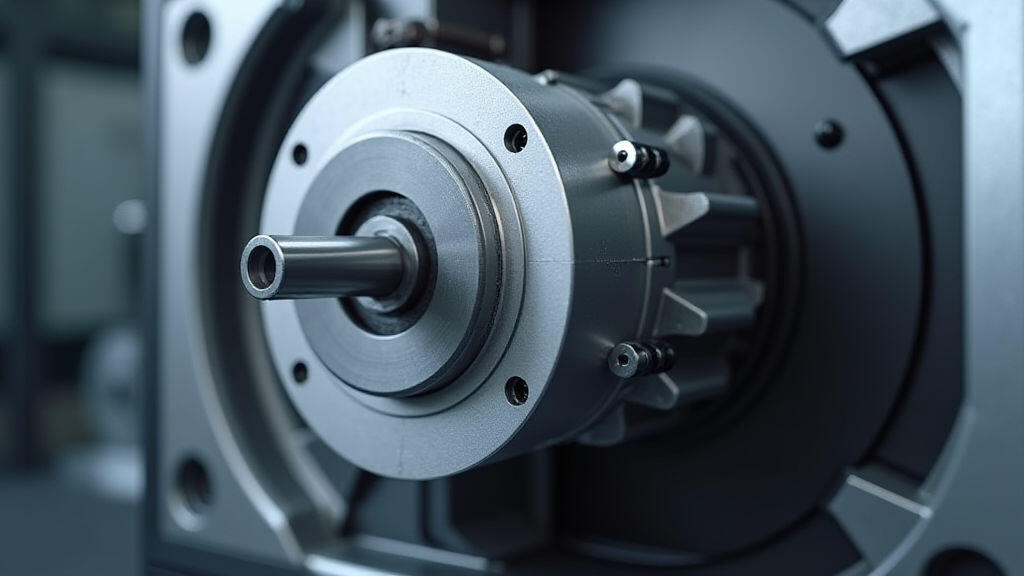

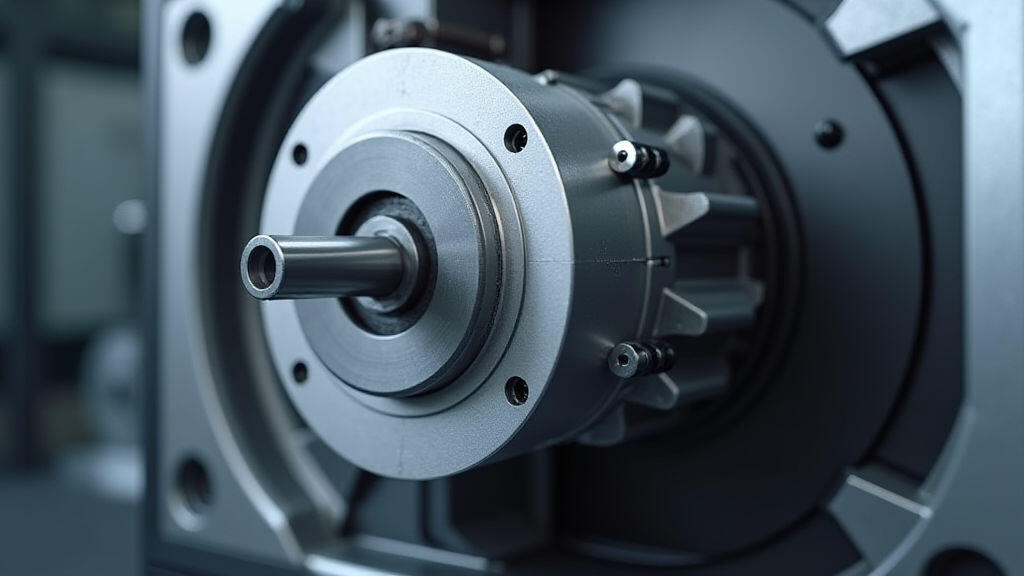

The global CNC (Computer Numerical Control) machine tool market is experiencing robust growth, fueled by the increasing demand for precision manufacturing across diverse industries like aerospace, automotive, and medical. This growth, however, isn't simply about more machines; it's about smarter, more efficient machines. A critical, often overlooked, component driving this evolution is the DC gear motor – the workhorse powering the precise movements vital for CNC operations.

Traditionally, AC gear motors were the prevalent choice. However, a paradigm shift is underway. CNC machine tool manufacturers are increasingly prioritizing the selection of high-performance DC gear motors, driven by a confluence of factors including enhanced precision, energy efficiency, quieter operation, and the integration of advanced control systems. This trend is particularly relevant in the current environment where sustainability and cost-effectiveness are paramount concerns, echoing broader industry focuses on Industry 4.0 and smart manufacturing.

AC gear motors have served CNC industries well, providing reliable power transmission. But they face significant limitations in meeting the demanding requirements of modern CNC machines. These limitations often manifest as:

DC gear motors offer compelling advantages that directly address the shortcomings of AC counterparts, making them increasingly the preferred choice for CNC machine tool manufacturers. Here’s a detailed look:

Several specific technologies are contributing to the performance optimization of DC gear motors within CNC applications:

Companies like MES-Drive are at the forefront of this industry transformation. MES-Drive specializes in the design, development, and manufacturing of high-performance DC gear motors tailored for CNC applications. They offer a comprehensive portfolio of solutions, encompassing harmonic drives, precision planetary gearboxes, and BLDC motors, alongside advanced motor control systems.

MES-Drive's commitment to innovation extends to custom-engineered solutions, working closely with CNC machine tool manufacturers to meet their specific performance requirements. Their focus on quality, reliability, and energy efficiency has established them as a trusted partner for leading CNC machine tool brands. The company leverages advanced simulation and testing capabilities to ensure optimal motor performance and longevity.

The increasing adoption of Industry 4.0 principles and smart manufacturing technologies is further accelerating the demand for high-performance DC gear motors. CNC machine tools are becoming increasingly interconnected, requiring precise and responsive motion control to support advanced features like adaptive machining, collaborative robots (cobots), and real-time process monitoring.

These advancements demand motors that can seamlessly integrate into complex control architectures and dynamically adjust to changing operating conditions. DC gear motors, with their superior control capabilities and energy efficiency, are ideally suited to meet these evolving needs.

The shift towards DC gear motors in CNC machine tool manufacturing is not merely a trend; it’s a strategic move to enhance precision, improve efficiency, and embrace the principles of smart manufacturing. The superior performance characteristics of DC gear motors, coupled with advancements in motor control technologies, are enabling the development of more powerful, precise, and sustainable CNC machines.

In the context of current global economic uncertainties and the escalating push for environmentally responsible manufacturing, the importance of energy-efficient and highly precise CNC technology cannot be overstated. As the CNC market continues to expand, DC gear motors will play an increasingly vital role in powering the next generation of precision manufacturing solutions. The focus on optimizing DC gear motor selection is therefore a critical investment for CNC machine tool manufacturers seeking to remain competitive and meet the evolving demands of the industry. Ultimately, the ability to precisely and efficiently control motion is the key differentiator in the future of manufacturing, and DC gear motors are leading the charge.

Leave A Reply

Your email address will not be published. Required fiels are marked