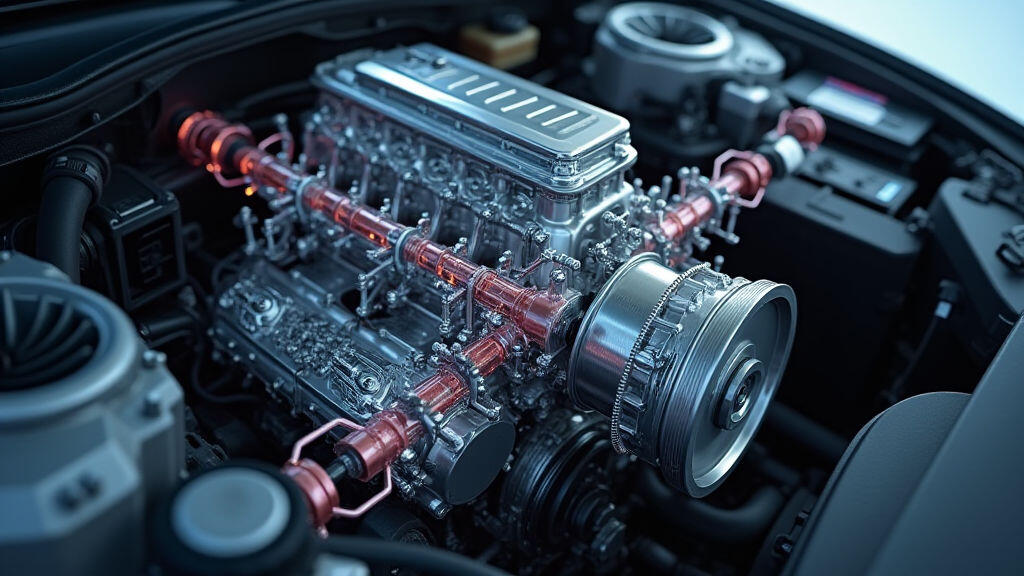

The automotive industry is undergoing a dramatic transformation. Driven by electrification, autonomous driving, and a growing demand for fuel efficiency, manufacturers are constantly seeking ways to improve vehicle performance and reduce costs. At the heart of many of these advancements lies the right-angle gear motor, a crucial component in a growing number of automotive applications. This article explores why automotive parts manufacturers are increasingly focusing on optimizing the performance of these vital motors, examining the driving forces, key performance parameters, and the technological advancements shaping the future of right-angle gear motor design.

The Rise of the Right-Angle Gear Motor in Automotive Applications

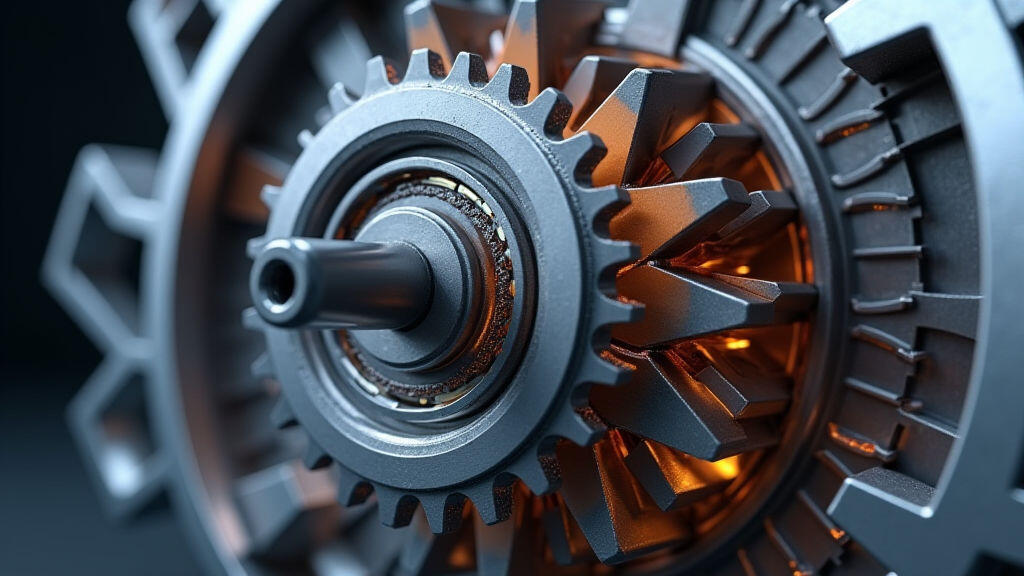

Right-angle gear motors are ubiquitous in modern vehicles, playing a vital role in diverse functions. Unlike straight-shaft gear motors, right-angle gear motors offer a 90-degree rotational output, enabling efficient power transmission in compact spaces. Their applications are rapidly expanding, driven by the following trends:

- Electric Vehicles (EVs): EVs rely heavily on electric motors for propulsion, but also require gear reduction systems for various auxiliary functions like power steering, air conditioning compressors, and braking systems. Right-angle gear motors are well-suited for these applications, offering torque multiplication and space efficiency. The increasing adoption of EVs is directly fueling demand for high-performance, efficient gear motors.

- Advanced Driver-Assistance Systems (ADAS): ADAS, including features like adaptive cruise control, lane keeping assist, and automatic emergency braking, rely on numerous sensors, actuators, and control systems. Right-angle gear motors provide the precise and reliable motion control needed for these systems to function effectively.

- Hybrid Electric Vehicles (HEVs): HEVs leverage both internal combustion engines and electric motors for improved fuel efficiency. Right-angle gear motors are essential for integrating these systems and optimizing power distribution.

- Autonomous Driving: Autonomous vehicles necessitate sophisticated control systems and precise mechanical components. The need for reliable and compact power transmission in autonomous vehicle platforms makes right-angle gear motors indispensable.

The automotive market size for gear motors is projected to reach billions of dollars in the coming years, with right-angle gear motors holding a significant share. This expansion underscores the importance of optimizing their performance.

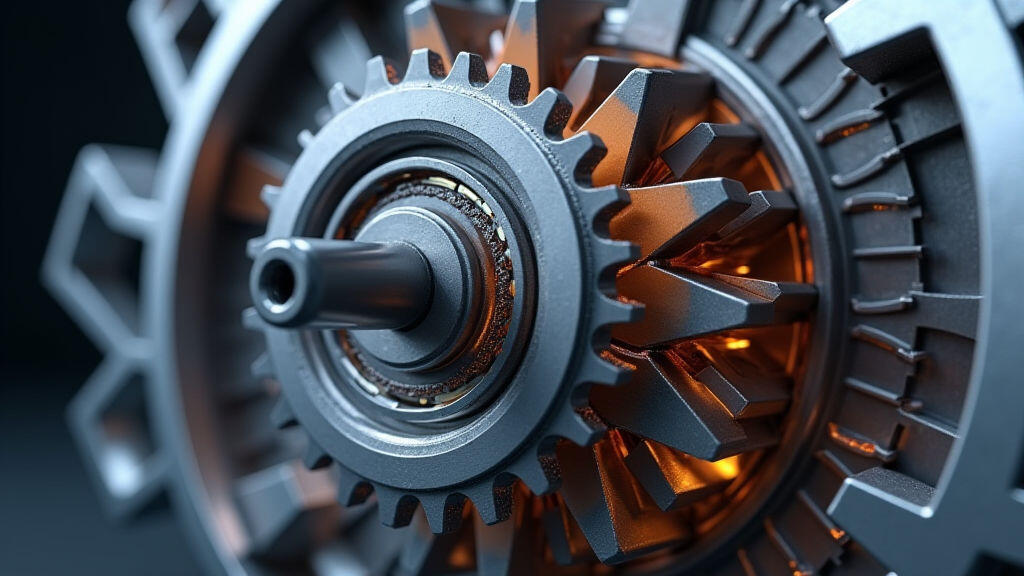

Optimizing right-angle gear motor performance involves focusing on several key parameters:

- Efficiency: Energy consumption is a critical concern in the automotive industry. Improving gear motor efficiency directly contributes to increased vehicle range in EVs and reduced fuel consumption in HEVs. Manufacturers are striving for efficiencies exceeding 90% under various load conditions. This involves minimizing friction losses within the gear mesh and optimizing the motor's electromagnetic design.

- Torque Density: Torque density, which is the amount of torque produced per unit volume, is paramount for achieving compact and lightweight designs. Higher torque density translates to smaller, lighter gear motors capable of delivering the required power. Advanced materials and optimized gear designs are key to boosting torque density.

- Reliability and Durability: Automotive applications demand exceptional reliability and durability. Right-angle gear motors must withstand harsh operating conditions, including temperature fluctuations, vibration, and shock loads. Improving lubrication systems, minimizing wear, and using robust materials enhances reliability.

- Noise and Vibration (NVH): Reducing noise and vibration is a growing concern in the automotive industry, driven by consumer demand for quieter and more comfortable vehicles. Optimized gear tooth profiles, improved manufacturing processes, and advanced damping techniques help minimize NVH.

- Weight: Weight reduction is a major focus in automotive engineering, particularly in EVs. Manufacturers are continuously seeking ways to minimize the weight of gear motors without compromising performance or reliability. This often involves innovative materials like lightweight alloys and optimized structural designs.

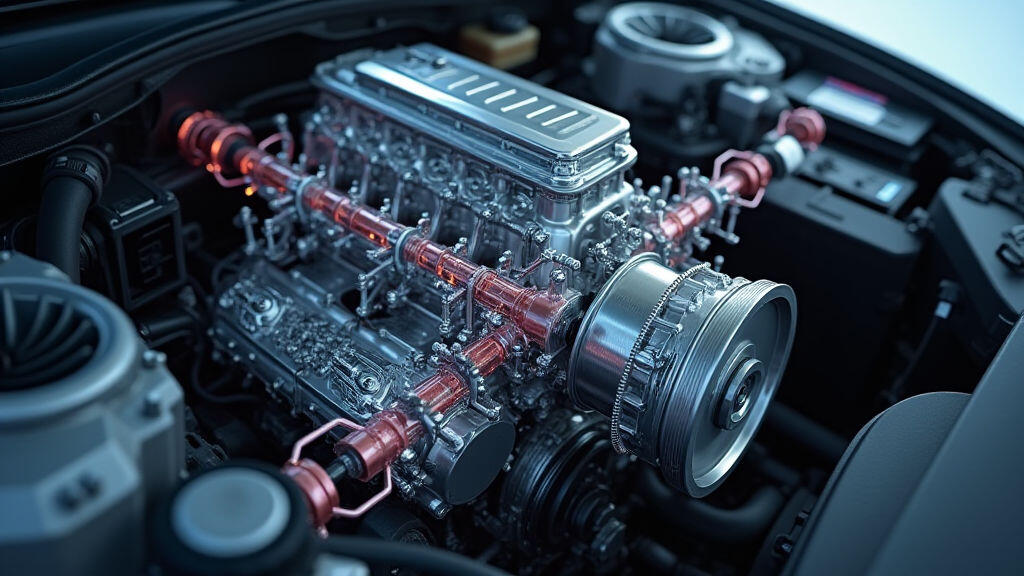

Technological Advancements Driving Optimization

Several technological advancements are enabling significant improvements in right-angle gear motor performance:

- Advanced Materials: The use of lightweight alloys like aluminum and magnesium, as well as high-strength steels, is reducing motor weight while maintaining structural integrity. Furthermore, advanced polymers are being used for housings and other components, offering improved resistance to corrosion and vibration.

- Precision Manufacturing: Advanced manufacturing techniques, such as CNC machining and additive manufacturing (3D printing), enable the creation of complex gear geometries and optimized internal designs. This allows for enhanced efficiency, torque density, and reduced weight.

- Improved Lubrication Systems: Novel lubrication systems, including advanced oil formulations and optimized lubrication delivery methods, are minimizing friction losses and extending motor lifespan. The use of electric lubrication systems, which precisely control oil flow, is gaining traction.

- Smart Motor Control: Integrating sensors and control algorithms into right-angle gear motors enables real-time monitoring of performance parameters and adaptive control strategies. This allows for optimizing efficiency, preventing overheating, and extending motor lifespan. Predictive maintenance capabilities are also becoming increasingly important.

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD): These simulation tools are being used to optimize gear designs, predict thermal behavior, and minimize noise and vibration. FEA allows engineers to analyze stress distribution, while CFD is used to simulate airflow and optimize cooling systems.

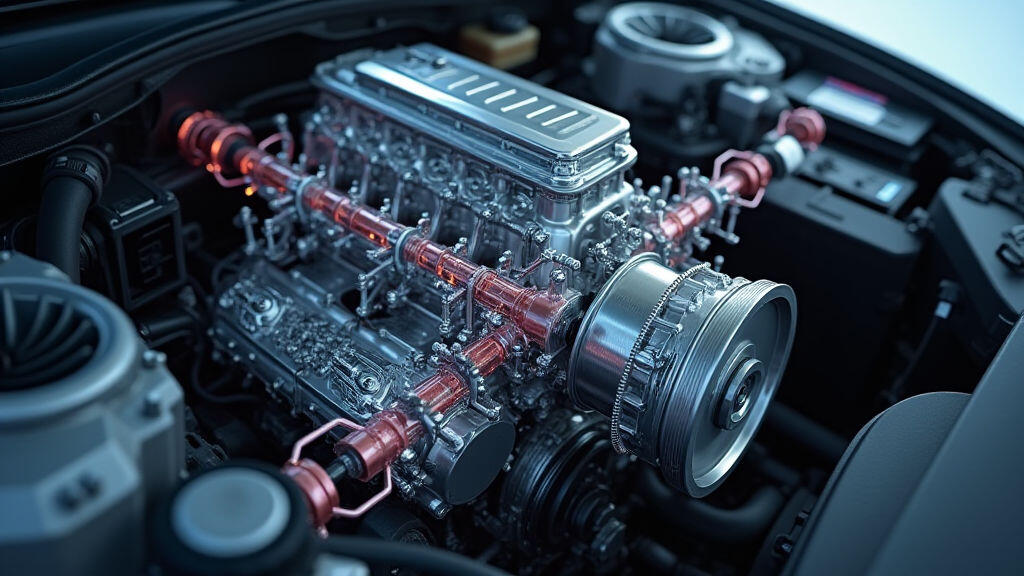

Companies like MES-Drive are at the forefront of this revolution, developing and implementing advanced technologies to optimize right-angle gear motor performance. MES-Drive leverages FEA simulations, advanced manufacturing techniques, and smart motor control to deliver high-efficiency, lightweight, and reliable gear motors tailored to the specific needs of automotive manufacturers. Their focus on precision engineering and material science allows for pushing the boundaries of performance. MES-Drive’s modular design approach also allows for customization and easy integration into various vehicle platforms.

Conclusion: Powering the Future of Automotive Mobility

The increasing demand for EVs, ADAS, and autonomous driving is undeniably driving the evolution of right-angle gear motors. Manufacturers are intensifying their focus on performance optimization, driven by the need for increased efficiency, reduced weight, enhanced reliability, and improved NVH. Technological advancements in materials, manufacturing, lubrication, and control systems are paving the way for significant breakthroughs. Companies like MES-Drive are leading this charge, developing cutting-edge solutions that will power the future of automotive mobility. As the automotive industry continues its rapid transformation, the right-angle gear motor will remain a critical component, and its optimization will be essential for achieving the performance goals of the next generation of vehicles. The increasing emphasis on these factors, particularly within the context of global sustainability efforts and the push for electric mobility, positions right-angle gear motor performance optimization as a key area of investment and innovation for years to come.

Leave A Reply

Your email address will not be published. Required fiels are marked