The robotics industry is experiencing explosive growth, fueled by advancements in artificial intelligence (AI), automation, and the increasing demand for efficient and adaptable solutions across various sectors – from manufacturing and logistics to healthcare and even space exploration. At the heart of every robotic system lies its core components, and among these, gear motors play a pivotal role. Choosing the right gear motor isn’t simply about picking a product with the right torque; it’s about a precise balance of power and speed ratio to maximize efficiency, performance, and ultimately, the success of the robotic application. This article dives into the critical factors influencing gear motor selection, laying out a practical guide for engineers and robotics professionals to ensure optimal efficiency and unlock the full potential of their robotic equipment.

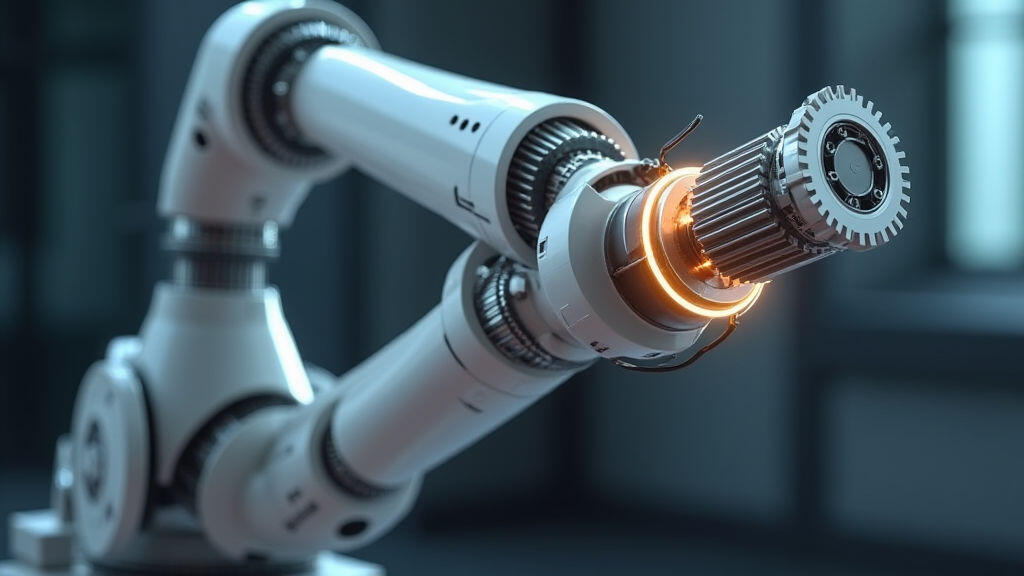

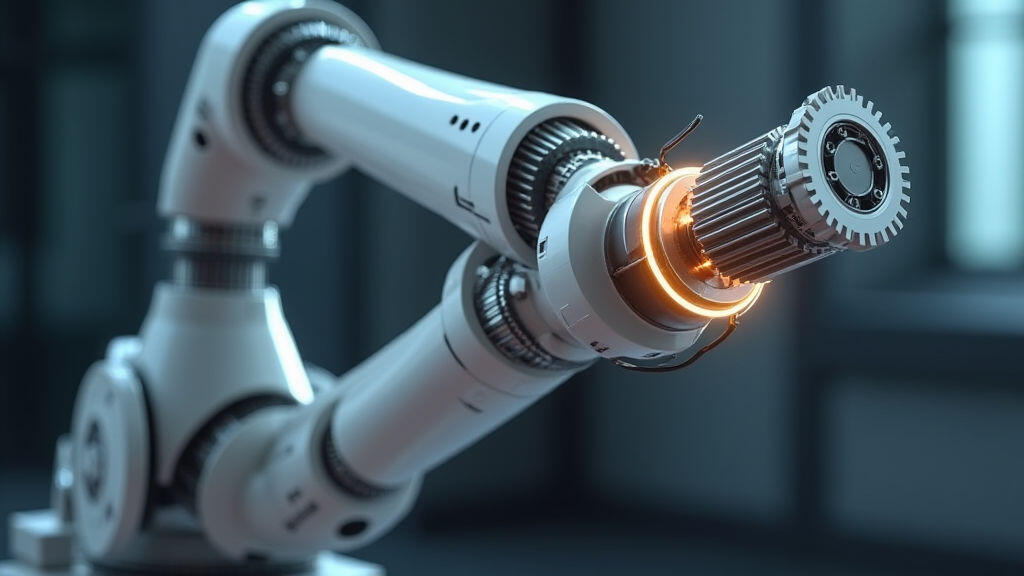

Robots are rarely designed to operate at the high speeds and power levels required for many tasks. Motors, in their raw form, often deliver excessive speed and insufficient force. This is where gear motors step in. A gear motor combines an electric motor with a gearbox to modify the motor's output, primarily reducing speed while simultaneously increasing torque. This modification is crucial for achieving precise movements, powerful force application, and overall system efficiency in robotics.

Consider a robotic arm tasked with delicate assembly. A high-speed motor would lack the necessary control and force to accurately position components. Conversely, a low-speed, high-torque motor might be too slow to meet production deadlines. The ideal solution lies in a gear motor that bridges this gap, providing the necessary combination of speed and torque for the task at hand. The rapid development of collaborative robots ("cobots") further underscores this need, requiring gear motors capable of both high precision and safe, controlled force applications.

To effectively select a gear motor, a thorough understanding of power and speed ratio is paramount.

Power: Measured in Watts (W), power represents the rate at which work is done. For robotics, power determines the force a motor can exert and the speed at which it can apply that force. Higher power translates to the ability to lift heavier objects, accelerate faster, or perform tasks requiring significant force.

Speed Ratio: This is the ratio between the motor's output speed and the gearbox's output speed. A higher speed ratio indicates a lower output speed and a higher output torque. It’s calculated by dividing the motor's RPM (revolutions per minute) by the gearbox's RPM. For example, a 10:1 speed ratio means the motor rotates 10 times for every 1 revolution of the output shaft.

Selecting the right gear motor involves a systematic approach, taking into account the specific requirements of the robotic application. Here's a breakdown of the key steps:

Define the Task: Clearly articulate the tasks the robot will perform. This includes understanding the required force, speed, precision, and range of motion. For instance, is the robot lifting, pushing, rotating, or performing repetitive motions?

Calculate the Required Torque: Determine the torque needed to accomplish the task, considering the weight of the load, friction, and acceleration requirements. This often involves complex calculations and simulations. Using tools like mechanical analysis software can be very beneficial.

Determine the Required Speed: Establish the necessary speed for each part of the robot's motion profile. Consider the acceleration and deceleration rates needed to avoid jerky movements and ensure smooth operation.

Calculate the Necessary Power: Once you have the torque and speed requirements, use the following formula:

*Power (Watts) = Torque (Nm) * Angular Velocity (rad/s)*

You'll need to convert RPM (revolutions per minute) to rad/s (radians per second) using the formula:

*Angular Velocity (rad/s) = (RPM * 2π) / 60*

Select the Gear Ratio: Based on the required power and speed ratio, choose a gearbox that achieves the desired output speed while providing sufficient torque. Manufacturers like MES-Drive offer a wide range of gearboxes with varying ratios to suit diverse applications.

Motor Selection: Based on the determined power requirement, select a motor with sufficient power output. Consider factors like voltage, current, and efficiency.

Efficiency is a critical factor in robotics, directly impacting energy consumption, operational costs, and overall system lifespan. A gear motor's efficiency indicates how effectively it converts electrical power into mechanical power. Higher efficiency means less energy is wasted as heat, leading to lower operating costs and reduced environmental impact.

MES-Drive gear motors are designed with advanced materials and optimized designs to maximize efficiency. They often incorporate features like high-quality bearings, precision gears, and efficient motor windings to minimize energy losses.

The robotics industry is constantly evolving, with emerging trends like edge computing, digital twins, and AI-powered automation driving demand for more sophisticated and efficient gear motors.

Choosing the right gear motor is a fundamental step towards building efficient, reliable, and high-performing robotic systems. A careful analysis of power and speed ratio requirements, combined with a focus on efficiency, is crucial for maximizing the potential of robotics in various applications. As robotics continues to integrate with AI and become more sophisticated, the demand for innovative gear motor solutions will only increase. Companies like MES-Drive are at the forefront of developing advanced gear motors that meet the evolving needs of the industry, ensuring that robots are not only powerful but also energy-efficient and sustainable. In the context of the current push for sustainable manufacturing and increased automation driven by AI, optimizing gear motor selection is no longer just a technical consideration; it’s a crucial factor in achieving long-term operational and environmental success.

Leave A Reply

Your email address will not be published. Required fiels are marked