Robotics is no longer confined to cutting‑edge laboratories; it is now a cornerstone of modern manufacturing, logistics, and even healthcare. At the heart of every robotic system that moves, lifts, or assembles components lies an electric motor, often powered by a variable frequency drive (VFD). While it may seem that any motor equipped with a VFD will do the job, the real performance, energy savings, and operational life of a robot hinge on a careful match between the motor and the VFD. This article breaks down the essential considerations for selecting a VFD motor that elevates robotic equipment to peak efficiency.

A VFD is more than a speed controller; it is the brain that adapts the motor’s power supply to match changing job demands. By varying the frequency of the alternating supply, the drive can modulate speed, torque, and direction with exceptional precision. For robotics, where position accuracy and smooth acceleration are vital, the VFD also compensates for load variations, ensuring consistent motion.

Before you even look at motor specs, ask these questions:

Collecting this data gives you a clear performance envelope—speed, torque, and load curves—that the motor must span.

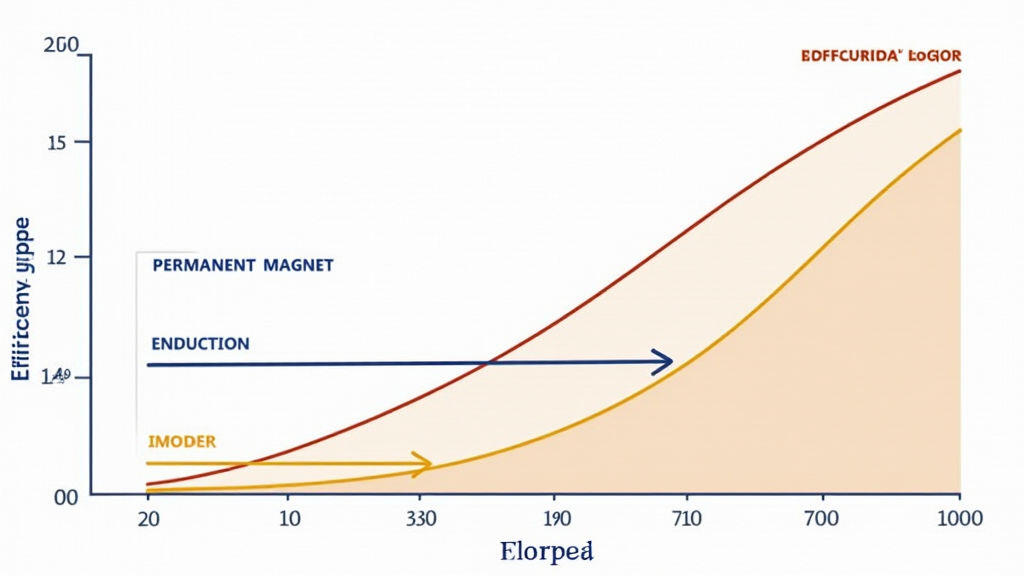

The classic “torque‑speed” relationship is key. In a VFD‑driven system, torque remains nearly constant while speed is reduced; this gives a shallow torque profile that is ideal for robotics. To choose the right motor:

Motor efficiency is a direct determinant of energy consumption. A motor with a high efficiency rating (IE3 or IE4 in IEC terms, or 80 %+ in the U.S.) can reduce operating costs by 10‑20 %. Pay attention to:

Choosing an efficient motor also reduces heat generation, which in turn allows a smaller, cheaper VFD.

Robotics applications often have space constraints. Review:

A compact motor that still delivers the required torque can save both cost and the design of the robot’s frame.

Industrial robots work in varied settings:

If the motor’s protection level is insufficient, you may need an enclosure or additional shielding—adding cost and installation time.

Not all motors play well with every drive. Key points:

Compatibility saves troubleshooting and extends overall system life.

A motor that may cost more upfront but lasts longer yields cost benefits across the robot’s lifetime.

Assess the Total Cost of Ownership (TCO) rather than focusing solely on purchase price.

Consider a 10‑kg pallet stacker that moves quickly across the floor:

As Industry 4.0 accelerates, motors are becoming smarter. Embedded intelligence can adjust motor parameters in real time, reducing wear and improving safety. Battery‑powered robots for logistics are also pushing the envelope on motor efficiency. Companies that choose motor + VFD pairs with scalability for future upgrades will stay ahead of the curve.

Selecting the right variable frequency drive motor is a decisive factor in robotics equipment efficiency. By aligning torque and speed requirements, prioritizing efficiency, fitting size and environmental constraints, ensuring VFD compatibility, and considering long‑term maintenance, you can dramatically cut energy use and prolong system life. In the high‑stakes world of automation, the motor choice is not just a technical detail—it’s a strategic investment that impacts productivity, cost, and competitiveness.

For the next wave of robotic solutions, embrace a thoughtful motor selection process. Energy efficiency, reliability, and adaptability will be the hallmarks of the robots that lead the industries of tomorrow.

Leave A Reply

Your email address will not be published. Required fiels are marked