In the fast‑moving world of logistics and consumer goods, packaging lines must move quickly, flexibly and reliably. One often overlooked yet decisive factor in achieving this performance is the choice of the micro DC gear motor that drives each conveyor, feeder, or folding unit. This article walks through what to look for when selecting these motors and how the right choice can elevate overall equipment efficiency.

Packaging lines sit at the intersection of production volume and supply‑chain speed. Even a tiny drop in throughput can ripple through a company’s profitability. Besides speed, efficiency translates into lower energy bills, reduced maintenance downtime, and longer machine life. In a climate‑conscious industry, efficient drives also help meet aggressive sustainability targets.

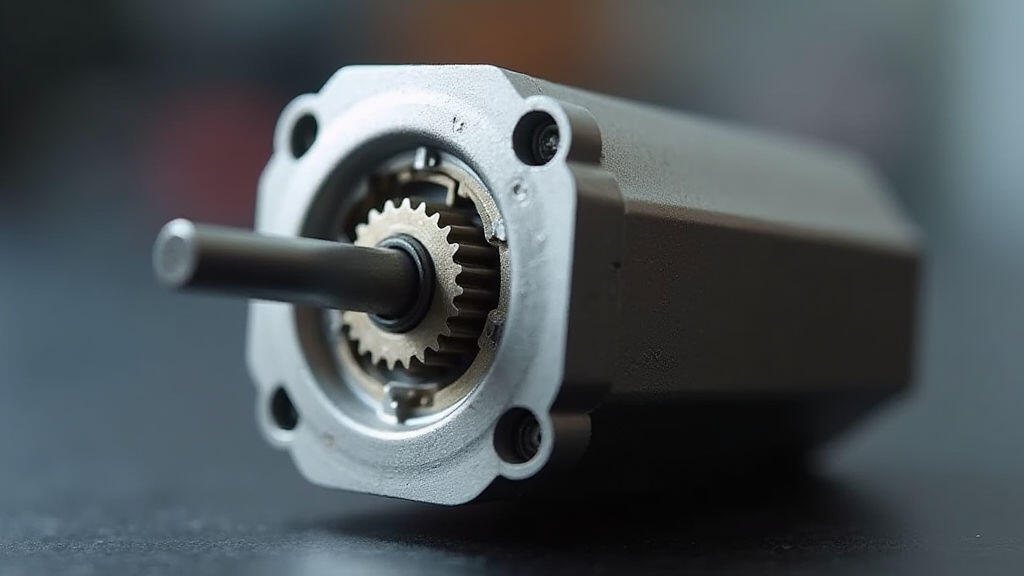

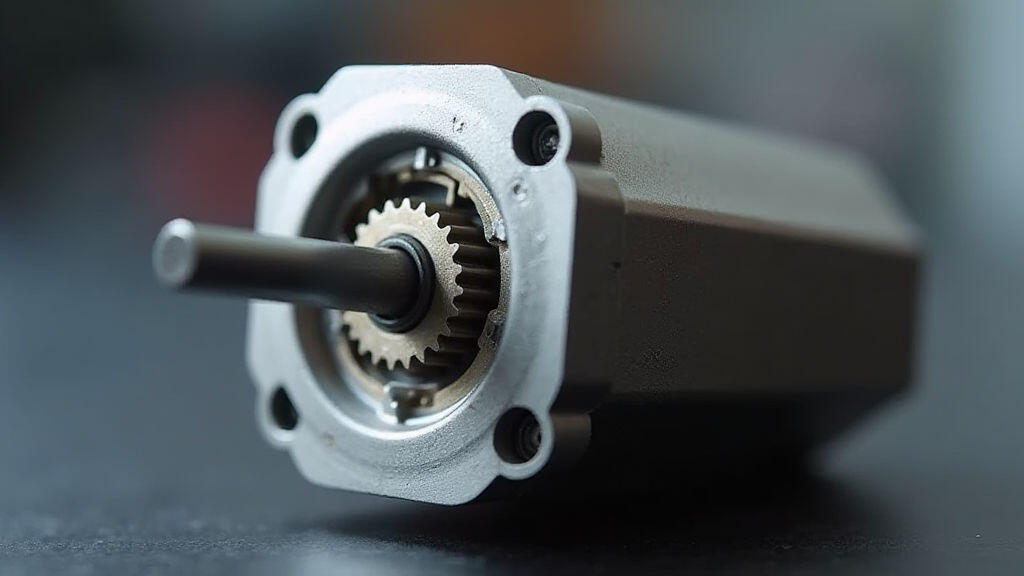

Micro DC gear motors are prized for their compactness and precise speed control. They combine a small DC motor with a planetary gear box to deliver high torque in a slim package. This makes them ideal for tight mounting spaces on chutes, screw feeders, and robotic pinchers. Their brushless variants further lower maintenance needs and extend operating life.

While it’s tempting to pick the cheapest motor that “looks good,” overlooking certain specifications can erode the gains you’re hoping for. Below is a simplified checklist that translates technical data into real‑world benefits.

Torque & Speed Requirements

• Determine the peak load and desired RPM for your specific process step.

• Choose a gear ratio that delivers at least 1.3× the required torque at the lowest operating speed; this margin protects against stall and reduces motor rotation stresses.

Power Efficiency (EER)

• Look for motors with an energy efficiency rating of 90 % or higher.

• Efficient drives will shave power consumption by 10‑15 % while maintaining the same output, translating directly to cost savings.

Control & Feedback

• If the process demands variable speeds (e.g., adjustable product width), choose a motor with a built‑in encoder or compatible with external motion controllers.

• Closed‑loop control reduces overshoot and recovers speed more quickly after a disturbance.

Build & Protection

• For food‑grade or pharmaceutical packaging, select motors rated for IEC 60068‑1/3 (dust tight, temperature‑controlled).

• In harsher environments, consider IP65 or higher seals.

Thermal Management

• Check the motor’s heat dissipation method. Heat‑sinked designs with integrated thermal pads handle continuous duty better than air‑cooled versions.

Cost vs. Life‑Cycle Value

• Initial price is only part of the equation. Compare base price with projected energy savings, maintenance costs, and expected uptime to calculate pay‑back period.

1. Under‑rating torque – A motor that can barely meet load requirements spends more time running near its maximum, leading to instant wear.

2. Ignoring duty cycle – Motors rated for intermittent use may fail silently during long runs, causing unexpected downtime.

3. Forgetting integration complexity – Some high‑efficiency motors need specialized controllers. Skipping this step can negate efficiency gains.

By assessing the above parameters, you can count on a motor that retains performance even under varying operational stresses.

Today, several breakthroughs are shaping the next wave of packaging equipment.

Silicon Carbide (SiC) Drives – SiC semiconductors allow motors to handle higher voltages without heat generation, pushing overall system efficiency to new levels.

Digital Twin Integration – Pairing motors with real‑time data analytics lets maintenance teams detect drift before failures occur, dramatically reducing unplanned stoppage.

Compact High‑Efficiency Motors – Innovations in gear tooth geometry and magnetic material composition yield motors that are simultaneously smaller, lighter, and more efficient.

<mkimg prompt='A futuristic assembly line with glowing micro DC gear motors, sensors floating, networked data streams, label “Digital Twin & SiC integration’ />

These trends point toward a market where each motor is not only a power source but a data‑rich, self‑optimizing component. Companies investing in smart micro DC gear motors today stand to reap future returns in uptime, energy savings, and product safety.

Packaging equipment efficiency hinges on more than line speed; it relies heavily on the right micro DC gear motor. By focusing on torque‑speed matching, energy efficiency, control compatibility, protection ratings, and thermal capability, designers can select motors that keep the line humming and the costs low. Avoiding common pitfalls protects against premature wear and costly downtime. Finally, embracing emerging technologies such as SiC drives and digital twins promises even sharper efficiency gains and better assurance of quality compliance.

As sustainability and speed become ever more critical to success, the micro DC gear motor will remain a central piece of the packaging puzzle. Thoughtful selection today brings a competitive edge tomorrow.

Leave A Reply

Your email address will not be published. Required fiels are marked