Medical devices—from portable ultrasound scanners to advanced robotic surgery systems—rely heavily on reliable motion control. At the heart of many of these systems lies the gear motor, a compact powerhouse that converts electrical energy into precise mechanical motion. Selecting the right gear motor is not just a technical decision; it determines patient safety, product lifespan, and overall operational cost. This article walks through the essential steps of gear motor selection calculation, demystifying the process while keeping the language clear and engaging.

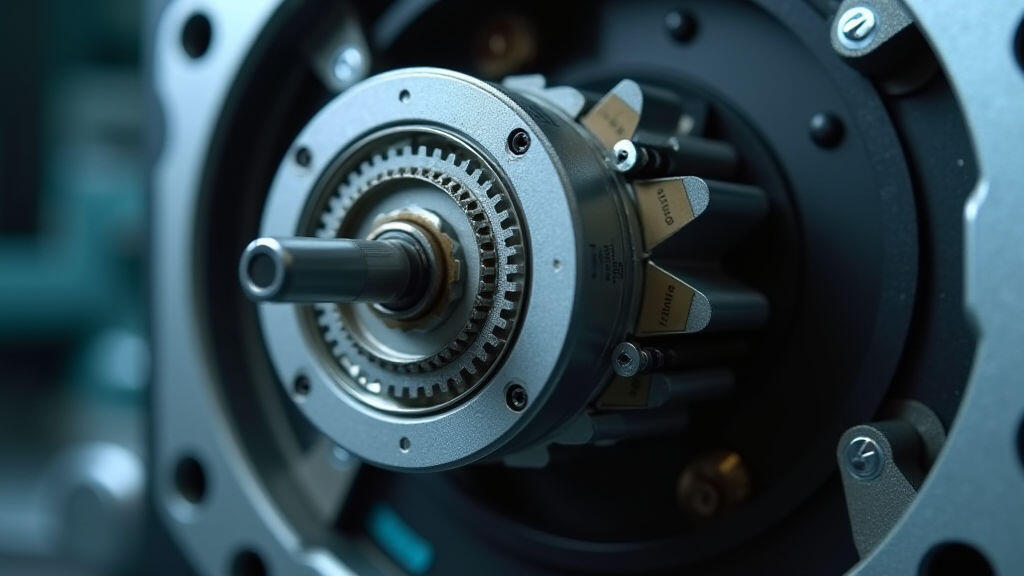

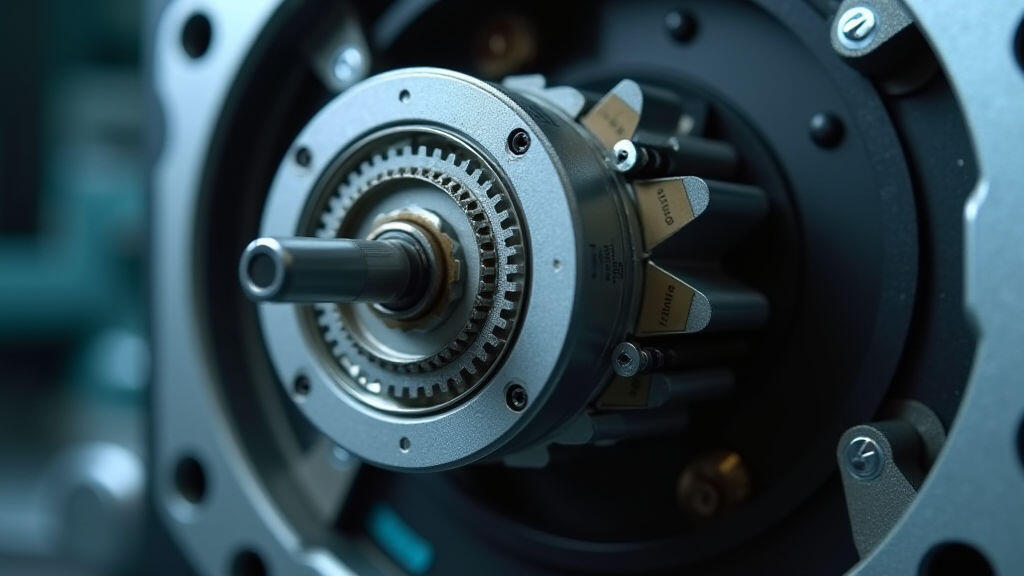

In a hospital setting, equipment must perform with zero compromise. A misbehaving motor can delay diagnostics, increase wear on components, or, in critical scenarios, affect patient outcomes. Gear motors play a dual role: they provide high torque at low speed (ideal for precise positioning) and can be assembled into compact, lightweight housings—a crucial attribute for mobile diagnostic units and wearable instruments.

When tackling the gear motor selection problem, keep these basics in mind:

Failing to account for any of these can push a device outside its safe operating envelope.

The calculation process can be broken into three parts: torque and speed determination, gear ratio selection, and motor sizing.

| Load Torque (N·m) | Operating Speed (RPM) |

|---|---|

| Example: 0.75 | 1000 |

Start with the functional requirement: how much force does the device need at the output? For a robotic arm that lifts 5 kg at 0.5 m, the torque would be T = m × g × r = 5 kg × 9.81 m/s² × 0.5 m ≈ 24.5 N·m. However, gear motors rarely operate at full load continuously; thus, multiply by a safety factor (e.g., 1.5) to obtain a design torque of ~36.8 N·m.

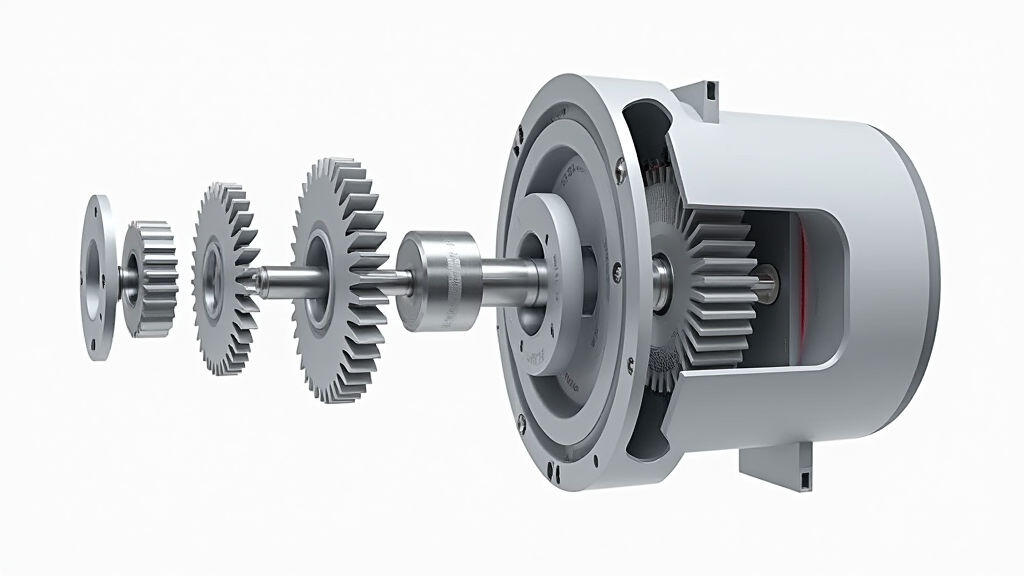

Gear ratio (i) is the ratio between the input speed (motor) and output speed (device). For high torque at low speed, a larger ratio is appropriate. If the desired device speed is 100 RPM and the motor can run at 10,000 RPM, the minimum ratio is 10,000 / 100 = 100:1. In practice, designers often settle for a slightly lower ratio (e.g., 80:1) to enhance robustness and allow for speed control flexibility.

The motor’s continuous torque (T_c) and speed (N_m) must satisfy:

T_c ≥ T_design / i and N_m ≥ i × N_output

Using the numbers above, with i = 80:1 and T_design = 36.8 N·m, we need a motor capable of at least 0.46 N·m continuous torque. The speed requirement becomes 80 × 100 = 8,000 RPM. Modern brushless DC (BLDC) motors often meet these specs while offering higher efficiency.

Mechanical power required at the output is:

P_o = T_design × ω_out (where ω_out = 2π × N_output/(60) rad/s)

With T_design = 36.8 N·m, N_output = 100 RPM:

P_o ≈ 36.8 × (2π × 100/60) ≈ 383 W

The motor must supply this under gear losses (~15% typical). So the input mechanical power must be roughly 383 / 0.85 ≈ 451 W. For a 12 V supply, current I = P_in / V ≈ 37.6 A—an impractical value for a compact medical device. Here, the engineer would either lower load torque, increase gear ratio further, or use a higher‑voltage supply (e.g., 48 V) to reduce current to manageable levels.

Visualizing the gear train and motor placement helps spot spatial clashes or thermal hotspots.

As the Internet of Medical Things (IoMT) expands, gear motors are evolving into intelligent components:

These developments promise lighter, more energy‑efficient devices—critically important for portable diagnostics, telemedicine, and remote surgical procedures.

Gear motor selection is foundational to medical equipment performance. By systematically evaluating torque, speed, gear ratio, and thermal constraints, engineers can design motors that deliver reliable motion, prolonged lifespan, and safety compliance— all while maintaining compactness and energy efficiency. As the industry moves toward smarter, connected devices, optimizing gear motor choices will underpin the next wave of breakthroughs in patient care. In short, the right gear motor is not just a component; it is the invisible driver that keeps lifesaving technologies moving smoothly.

Leave A Reply

Your email address will not be published. Required fiels are marked