The manufacturing sector is undergoing a profound transformation, driven by the rise of Industry 4.0 and the concept of Intelligent Manufacturing. At the heart of this revolution lies the integration of advanced technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) into production processes. Central to this transformation, and often overlooked, is the critical role of specialized mechanical components, particularly gear motors, in enabling the precision, efficiency, and adaptability demanded by modern CNC (Computer Numerical Control) machine tools. This article delves into the importance of understanding gear motors and explores their rapidly expanding applications within the context of Intelligent Manufacturing. We'll also highlight how companies like MES-Drive are leading the way in developing and supplying cutting-edge gear motor solutions for this evolving landscape.

CNC machine tools are the backbone of modern manufacturing, enabling the creation of complex parts with high accuracy and repeatability. The evolution of CNC technology has consistently demanded improvements in motion control – the ability to precisely and efficiently position cutting tools along multiple axes. Early CNC systems relied on relatively simple motor technology. However, the advancements in materials science, control systems, and the increasing complexity of manufactured parts have placed increasingly stringent demands on the performance of these motors. This includes requirements for smaller footprints, higher torque density, smoother operation, and increased lifespan – all of which are directly influenced by the type and quality of the gear motor used.

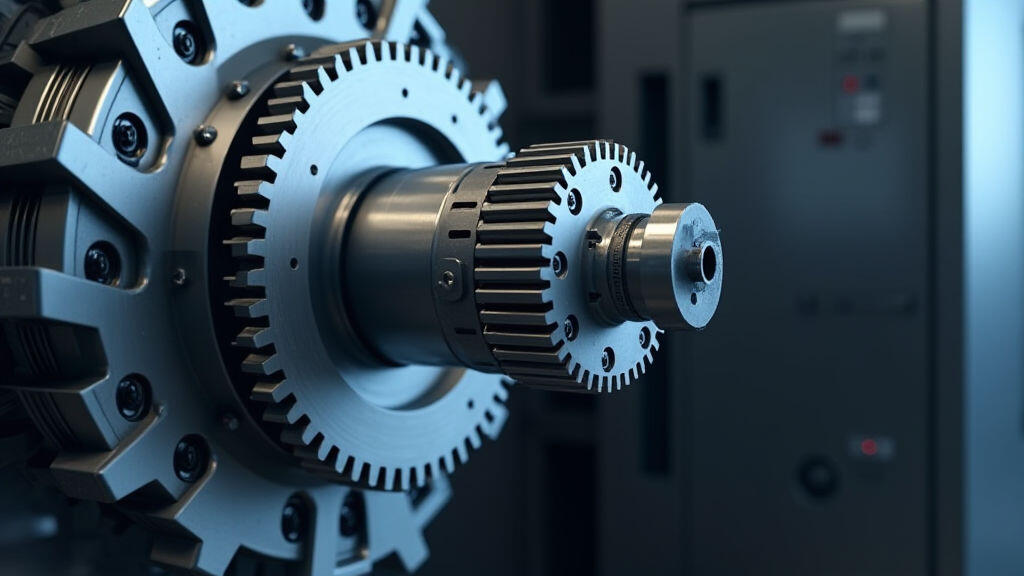

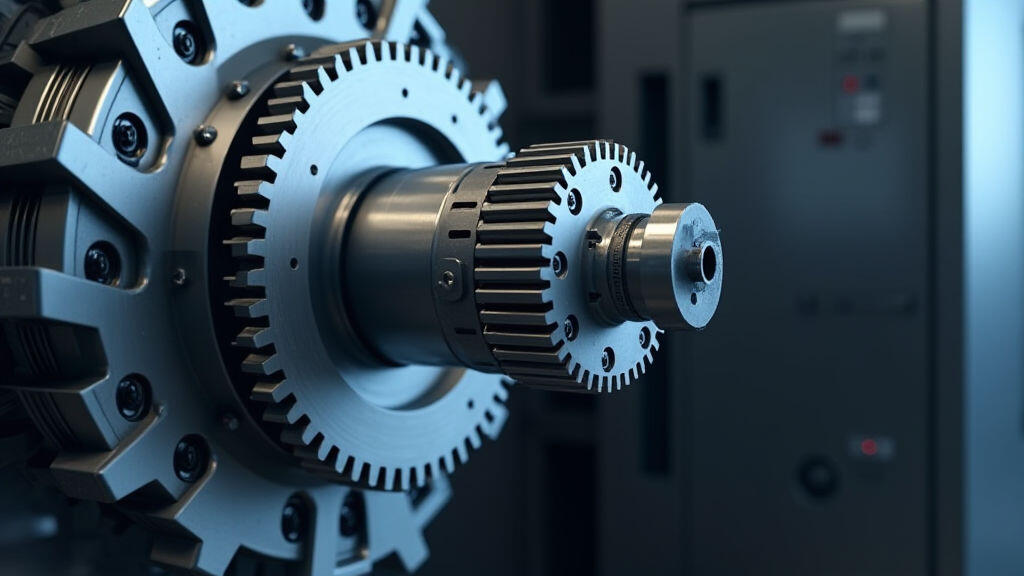

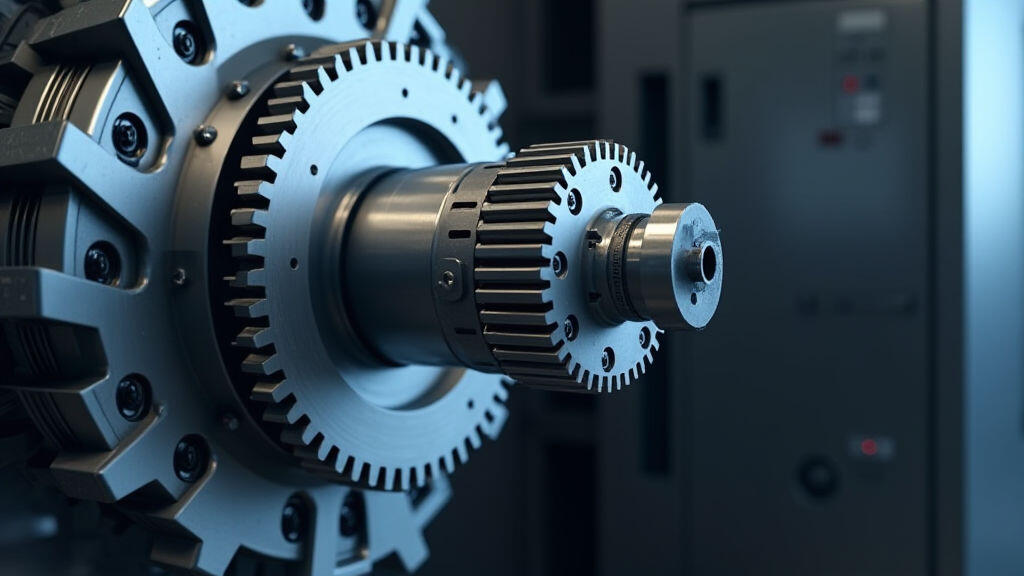

What are Gear Motors and Why are They Essential for CNC?

A gear motor combines the power of an electric motor with the mechanical advantage of a gearbox. The motor provides rotational power, while the gearbox reduces the rotational speed and increases the torque. This combination is ideal for CNC applications because:

- High Torque at Low Speed: CNC machines often require high torque to overcome the inertia of the workpieces and cutting tools, especially during rapid acceleration and deceleration. Gear motors deliver this torque at lower speeds than a direct-drive motor would.

- Precise Positioning: The gear reduction allows for incredibly fine control over the motor's position, critical for accurate machining operations.

- Compact Size: Gearmotors offer a higher power-to-volume ratio compared to other motor types. This is an important factor in the increasingly space-constrained designs of modern CNC machines.

- Smooth Operation: Well-designed gearboxes reduce vibration and noise, contributing to a smoother and more efficient machining process.

- Durability and Reliability: Gear motors, when properly maintained, offer excellent durability which is essential for continuous operation in demanding manufacturing environments.

Common types of gear motors utilized in CNC include: planetary gear motors, harmonic drive gearmotors, and worm gear motors – each offering different advantages in terms of efficiency, torque density, and speed range. The choice of gear motor depends on the specific requirements of the CNC application.

The Role of Intelligence: Gear Motors in Intelligent Manufacturing

The shift towards Intelligent Manufacturing necessitates the integration of sensors, data analytics, and AI into CNC machine tools. Gear motors are becoming increasingly 'smart' and interconnected, directly contributing to this intelligence. Key aspects include:

- Predictive Maintenance: Sensors integrated into the gear motor can monitor parameters like vibration, temperature, and current draw. AI algorithms can analyze this data to predict potential failures before they occur, minimizing downtime and optimizing maintenance schedules. MES-Drive offers gear motors with integrated IoT connectivity specifically designed for predictive maintenance applications.

- Adaptive Control: ML algorithms can be used to optimize motor control based on real-time feedback from the CNC machine. This enables adaptive control strategies that improve machining performance, reduce tool wear, and enhance surface finish. For example, the motor’s torque can be adjusted dynamically to compensate for variations in material hardness or cutting conditions.

- Energy Efficiency: AI can optimize motor operation to minimize energy consumption. This is particularly important in the context of sustainability initiatives and increasing energy costs. Smart gear motors can automatically adjust speed and torque based on the current workload, reducing energy waste.

- Remote Monitoring and Diagnostics: IoT connectivity allows for remote monitoring of gear motor performance, enabling engineers to diagnose problems and optimize operation from anywhere in the world.

MES-Drive: Driving Innovation in Gear Motor Technology

MES-Drive is a leading provider of high-quality gear motors for the CNC machine tool industry. They are actively involved in developing intelligent gear motor solutions that meet the evolving demands of Intelligent Manufacturing. MES-Drive differentiates itself through:

- Customization: MES-Drive offers a wide range of customizable gear motors to suit specific CNC applications.

- Advanced Materials: They utilize advanced materials like high-strength alloys and specialized coatings to enhance durability and performance.

- IoT Integration: MES-Drive's smart gear motors feature integrated IoT connectivity for remote monitoring and predictive maintenance.

- Focus on Efficiency: They are committed to developing energy-efficient gear motor solutions that reduce operating costs and minimize environmental impact.

Future Trends and the Convergence of Technologies

The future of gear motors in CNC machine tools is inextricably linked to the advancements in AI, ML, and IoT. We can expect to see:

- Increased Sensor Integration: Gear motors will become even more densely packed with sensors, providing a more comprehensive picture of their performance and condition.

- Edge Computing: Processing data directly on the gear motor (edge computing) will enable faster response times and improved reliability.

- Digital Twins: Creating digital twins of gear motors will allow engineers to simulate performance, optimize operation, and predict failures with unprecedented accuracy.

- Enhanced Cybersecurity: As more gear motors become connected, ensuring their cybersecurity will be critical to protect against malicious attacks and data breaches.

The ongoing development of gear motor technology, particularly in the context of Intelligent Manufacturing, signifies a shift away from purely mechanical solutions toward intelligent, data-driven systems. This convergence offers enormous potential for improving the efficiency, precision, and adaptability of CNC machine tools and ultimately, the manufacturing process as a whole. As the manufacturing industry continues to embrace Industry 4.0, the role of smart gear motors like those provided by MES-Drive will only become more critical.

Leave A Reply

Your email address will not be published. Required fiels are marked