The medical equipment industry is undergoing a rapid transformation, driven by the convergence of several powerful technologies, most notably Artificial Intelligence (AI), the Internet of Things (IoT), and advanced automation. This evolution is propelling the shift towards intelligent manufacturing—a paradigm focused on creating highly adaptable, efficient, and personalized medical devices. At the heart of this revolution lies a seemingly simple yet crucial component: the gear motor. Understanding and leveraging the core principles of gear motors is no longer just an engineering detail; it’s a fundamental requirement for success in modern medical equipment production.

Traditional manufacturing methods often involved rigid processes and standardized products. Intelligent manufacturing, in contrast, embraces flexibility and responsiveness. It leverages data-driven insights to optimize production, reduce waste, and personalize devices to individual patient needs. This involves integrating connected devices (IoT), predictive maintenance enabled by AI, and collaborative robots (cobots) working alongside human operators.

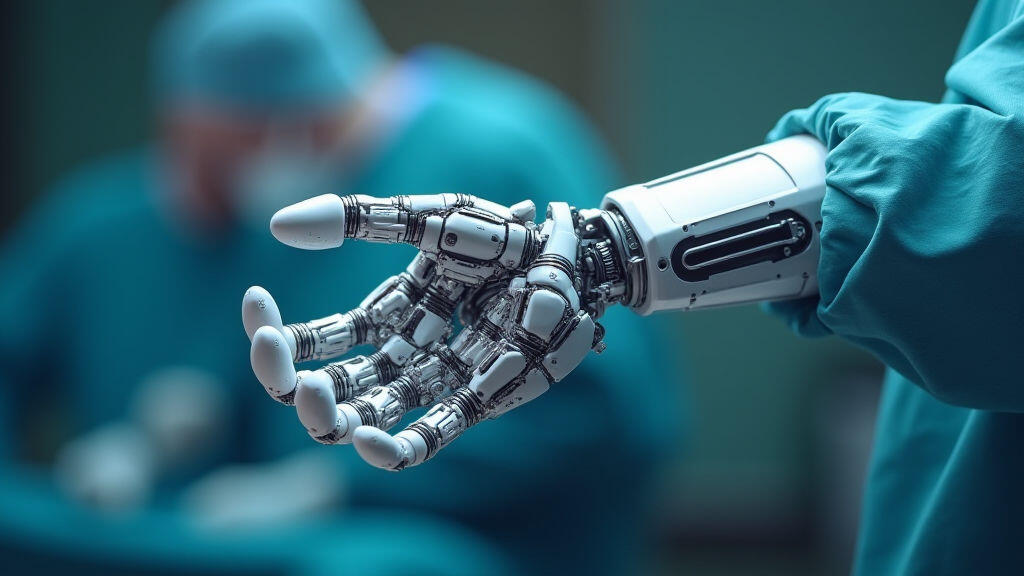

The demand for miniaturization, precision, and real-time control is particularly strong in medical devices. Consider implantable devices like pacemakers or drug delivery systems – their functionality and longevity depend heavily on the reliable performance of micro-motors. Similarly, surgical robots require unparalleled levels of accuracy and smooth, precise movements. These are areas where gear motors excel.

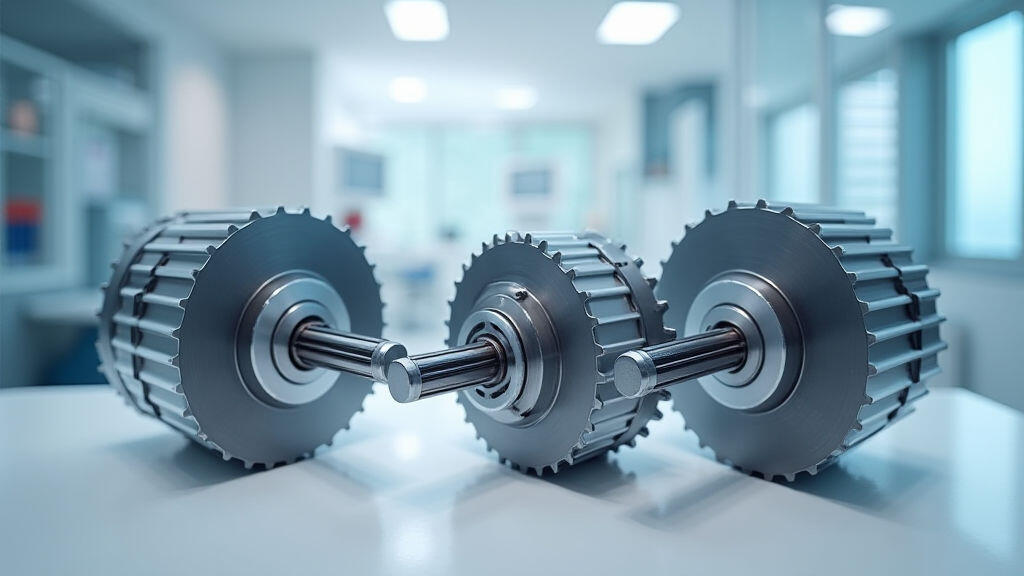

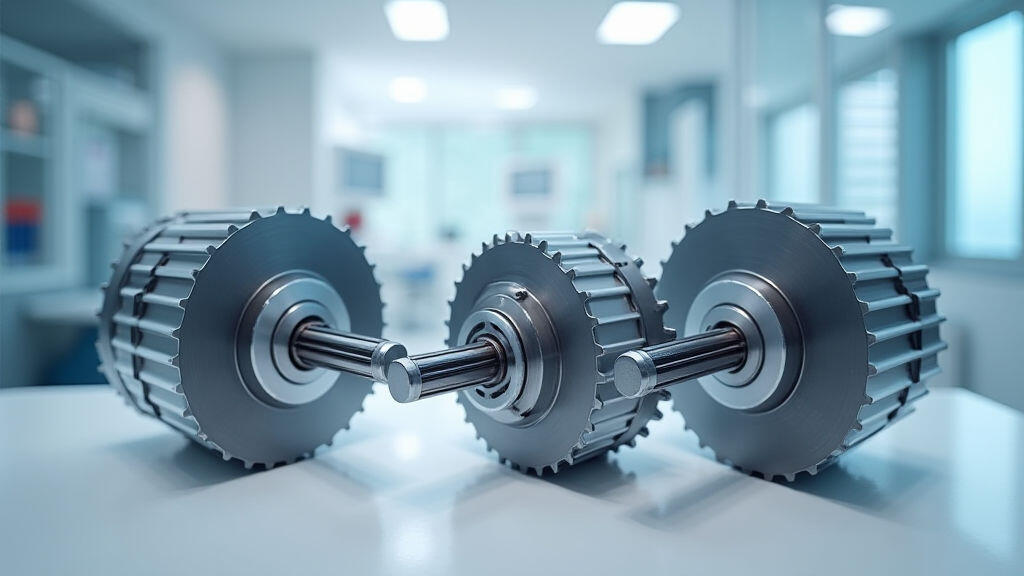

Gear motors are electromechanical devices that combine the power of electric motors with the speed reduction and torque amplification capabilities of gears. This combination makes them ideally suited for a wide range of medical equipment applications. Several types of gear motors are utilized, each offering unique advantages:

The integration of AI is further enhancing the capabilities of gear motors in intelligent manufacturing.

The Internet of Things (IoT) plays a vital role in data collection. Gear motors integrated with IoT sensors can transmit real-time performance data to a central system. This data can then be analyzed to:

MES-Drive is a leading provider of high-precision gear motor solutions specifically tailored for the medical equipment industry. We offer a comprehensive portfolio of gear motors, ranging from compact planetary units to high-torque worm gear drives. MES-Drive's commitment to innovation, combined with our expertise in AI and IoT integration, enables us to deliver solutions that meet the evolving needs of intelligent medical device manufacturing.

Our gear motors are designed with stringent quality controls and adhere to the highest industry standards (ISO 13485, FDA regulations). We also offer customized solutions to meet specific application requirements, collaborating closely with our customers throughout the design and manufacturing process. MES-Drive’s predictive maintenance platform helps medical device manufacturers proactively manage their gear motor assets, minimizing downtime and reducing maintenance costs.

The future of gear motors in intelligent manufacturing of medical equipment is incredibly promising. As AI and IoT technologies continue to advance, we can expect even more sophisticated applications, including:

Specifically, the current wave of generative AI coupled with advanced simulation techniques will significantly accelerate the design and optimization of these future gear motor systems. This will directly impact the efficiency and cost-effectiveness of producing innovative medical devices. The heightened focus on personalized medicine and remote patient monitoring will also drive demand for miniature, high-precision gear motors capable of operating in challenging environments.

The current global healthcare landscape, fueled by aging populations and a growing demand for advanced medical treatments, presents a unique opportunity for growth in the intelligent manufacturing of medical equipment. Gear motors, as essential components of these systems, are poised to play a pivotal role in shaping the future of healthcare.

In conclusion, gear motors are far more than just mechanical components; they are integral enablers of intelligent manufacturing in the medical equipment industry. The incorporation of AI, IoT, and advanced materials is transforming gear motor capabilities, leading to improved efficiency, reliability, and quality. MES-Drive is committed to leading this transformation by providing innovative gear motor solutions that empower medical device manufacturers to create safer, more effective, and more personalized healthcare solutions.

Leave A Reply

Your email address will not be published. Required fiels are marked