The Core Role of Gear Motor Manufacturers in the Intelligent Manufacturing of the Manufacturing Industry

The manufacturing industry is undergoing a seismic shift, propelled by the rise of intelligent manufacturing – also known as Industry 4.0. This revolution, characterized by interconnected systems, data-driven decision-making, and automation, is reshaping production processes, enhancing efficiency, and enabling unprecedented levels of customization. At the heart of this transformation lies a critical, often overlooked component: the gear motor. Gear motor manufacturers are no longer simply supplying power; they are becoming integral partners in building the smart factories of the future.

What is Intelligent Manufacturing and Why is it Important?

Intelligent manufacturing leverages technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), cloud computing, and big data analytics to create a highly responsive and adaptive production environment. The benefits are substantial. Companies are witnessing:

- Increased Efficiency: Optimized processes and reduced waste through real-time monitoring and analysis.

- Enhanced Quality: Predictive maintenance and quality control systems minimize defects and improve product reliability.

- Greater Flexibility: Agile production lines can quickly adapt to changing customer demands.

- Reduced Costs: Automation and optimized resource utilization lead to significant cost savings.

- Improved Safety: Robotics and automated systems reduce human exposure to hazardous environments.

The pandemic further accelerated the adoption of intelligent manufacturing. Supply chain disruptions highlighted the need for greater resilience and agility. Rising labor costs have amplified the demand for automation. Businesses are compelled to embrace intelligent manufacturing to remain competitive. A recent report by McKinsey estimates that Industry 4.0 could add $15.7 trillion to the global economy by 2030.

The Vital Role of Gear Motors in Intelligent Manufacturing

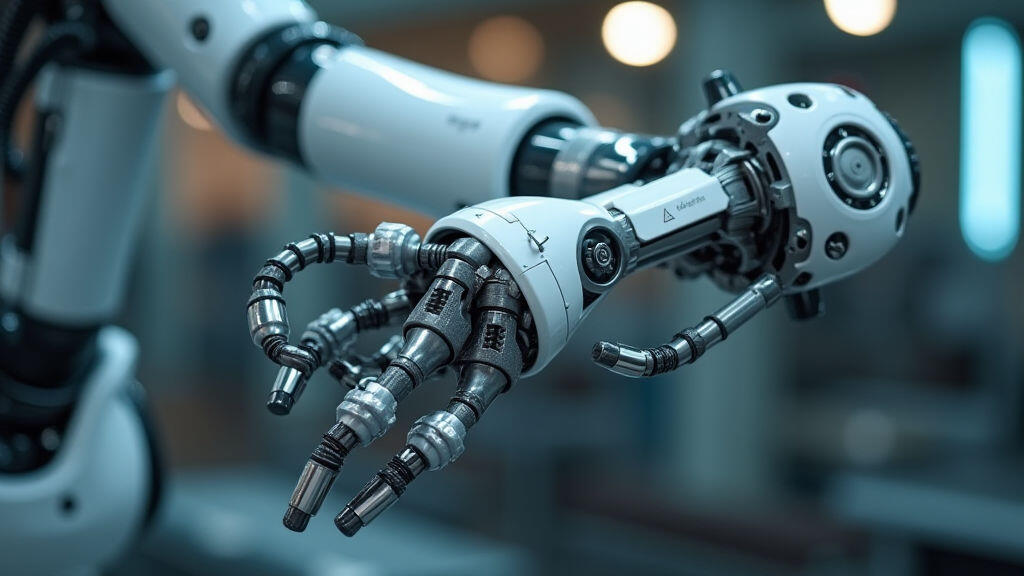

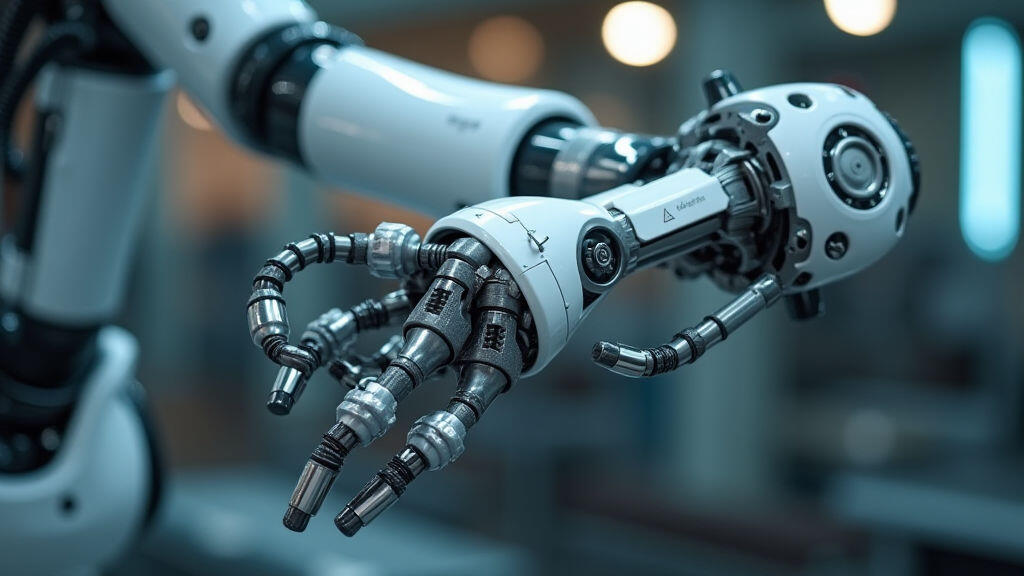

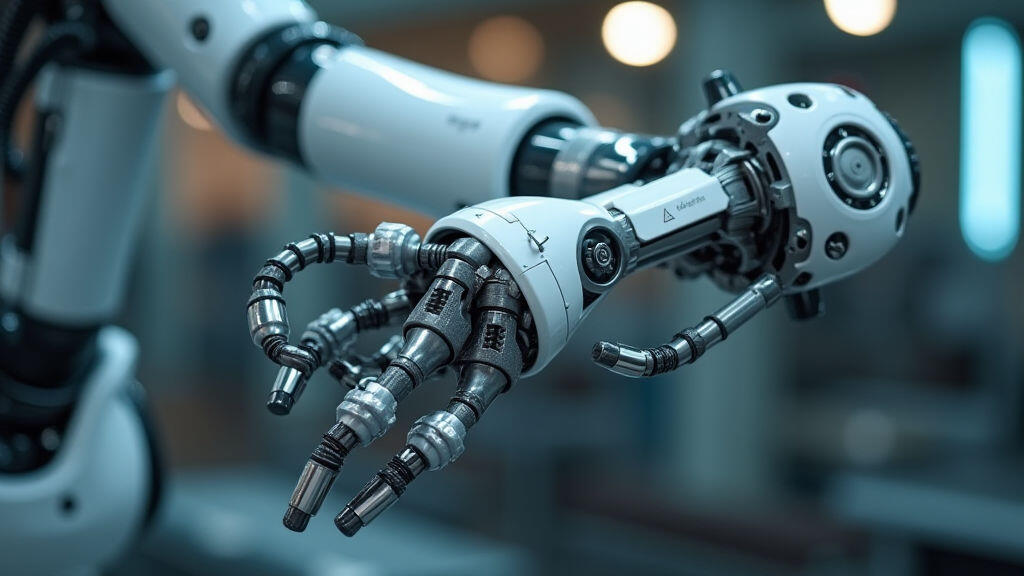

Gear motors are fundamental power transmission devices that combine a motor with a gearbox. They offer a powerful, compact, and highly efficient way to convert rotational energy into usable mechanical motion. In intelligent manufacturing, gear motors are essential for a wide range of applications:

- Robotics: Robots, the workhorses of automated factories, rely heavily on gear motors for precise and controlled movements. From pick-and-place operations to welding and assembly, gear motors provide the necessary torque and speed.

- Automated Guided Vehicles (AGVs) & Autonomous Mobile Robots (AMRs): AGVs and AMRs navigate factories transporting materials and products. Gear motors drive their wheels allowing for precise movement and obstacle avoidance.

- Conveyor Systems: Efficient material handling is critical for production flow. Gear motors power conveyor belts, ensuring smooth and continuous transfer of goods.

- CNC Machines: Computer Numerical Control (CNC) machines require precise positioning of cutting tools. Gear motors provide the torque and accuracy needed for intricate machining operations.

- Packaging Machinery: Modern packaging lines are highly automated. Gear motors drive mechanisms for filling, sealing, and labeling products with speed and precision.

- Sensor Actuators: In many advanced manufacturing processes, sensors need to trigger actuators to perform specific tasks. Gear motors are often used as actuators providing the necessary force for these actions.

The Evolution of Gear Motor Technology for Smart Factories

The rise of intelligent manufacturing is driving innovation in gear motor design and manufacturing. Key trends include:

- High Precision and Accuracy: Intelligent systems demand higher levels of precision. Manufacturers are developing gear motors with tighter tolerances and improved control systems.

- High Efficiency: Energy efficiency is a crucial consideration in smart factories, contributing to reduced operating costs and a smaller carbon footprint. Advanced materials, optimized gear designs, and efficient motor technologies are driving improvements in efficiency.

- Connectivity (IoT Integration): IoT connectivity allows for real-time monitoring of gear motor performance, enabling predictive maintenance and remote diagnostics. Sensors embedded in gear motors can collect data on temperature, vibration, and load, providing valuable insights into their health and operation. This allows for proactive interventions, minimizing downtime.

- Customization: Smart factories require tailored solutions. Gear motor manufacturers are offering customized gear motors designed to meet the specific needs of individual applications. This includes variations in torque, speed, gear ratio, and housing designs.

- Advanced Materials: The use of lightweight materials like aluminum alloys and composites are enhancing gear motor performance by reducing inertia and improving efficiency. Wear-resistant coatings extend lifespan and reduce maintenance requirements.

MES-Drive: Pioneering Gear Motor Solutions for Intelligent Manufacturing

MES-Drive is a leading gear motor manufacturer committed to delivering innovative solutions for intelligent manufacturing. We specialize in designing and producing high-precision, high-efficiency gear motors tailored to the demanding requirements of modern factories. MES-Drive's offerings include:

- Servo Gear Motors: For applications requiring precise speed and position control.

- Planetary Gear Motors: Offering high torque density and compact size.

- Harmonic Drive Gear Motors: Providing exceptionally high precision and smooth operation.

- Custom Gear Motors: Tailored to specific application requirements.

MES-Drive embraces IoT integration enabling remote monitoring and performance analysis. Our commitment to quality and innovation has made us a trusted partner for manufacturers across various industries.

Challenges and Future Outlook

While the potential of gear motors in intelligent manufacturing is immense, there are challenges to overcome. These include:

- Cybersecurity: Connecting gear motors to the internet introduces cybersecurity risks. Manufacturers must implement robust security measures to protect against cyberattacks.

- Data Management: The vast amount of data generated by connected gear motors requires efficient storage and analysis.

- Interoperability: Ensuring compatibility between different gear motor systems and other components in the intelligent manufacturing environment is crucial.

Looking ahead, the future of gear motors in intelligent manufacturing is bright. Advancements in AI and ML will enable more sophisticated predictive maintenance and performance optimization. The integration of digital twins – virtual replicas of physical systems – will allow for virtual testing and optimization of gear motor designs. As the manufacturing industry continues to evolve, gear motor manufacturers will remain at the forefront of innovation, empowering smart factories of the future. The current global semiconductor shortage, with the impending expansion of foundries worldwide, presents an opportunity to further innovate in gear motor control and power management. MES-Drive is actively researching and developing solutions to improve power efficiency and reduce dependence on scarce resources, solidifying its commitment to a sustainable and intelligent manufacturing future.

Conclusion

Gear motor manufacturers are not merely component suppliers; they are enablers of intelligent manufacturing. Their ability to provide high-performance, connected, and customizable gear motor solutions is essential for building the smart factories of the future. As Industry 4.0 gains momentum, the demand for advanced gear motors will continue to grow. Companies like MES-Drive are poised to lead this transformation, delivering the power and precision needed to drive efficiency, quality, and agility in modern manufacturing. The convergence of advanced motor technology, IoT connectivity, and AI-driven optimization is creating a new era of manufacturing excellence.

Leave A Reply

Your email address will not be published. Required fiels are marked