The robotics industry is experiencing exponential growth, driven by advancements in artificial intelligence (AI), automation, and the increasing need for efficient and reliable systems. At the heart of almost every robotic application lies the gear motor – a critical component that translates electrical energy into mechanical motion. Selecting the right gear motor is paramount to the success of a robotic project, influencing performance, longevity, and cost-effectiveness. This article delves into the key selection points and calculation methods for gear motors, specifically tailored for the demands of the modern robotics landscape. We’ll also explore how current trends, like collaborative robotics and edge computing, impact gear motor requirements.

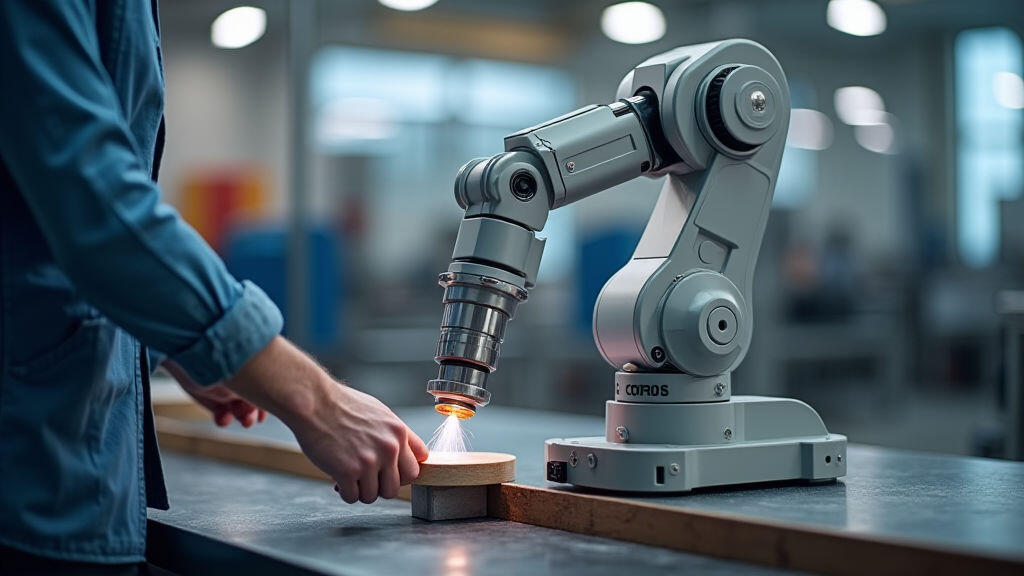

Robots aren't simply programmed to move; they need precise, controlled, and often powerful movements. Gear motors achieve this by combining the speed and power of an electric motor with the torque multiplication of a gear system. This combination allows for robots to perform a wide range of tasks – from delicate manipulation in a laboratory setting to heavy lifting in a manufacturing plant. The selection of an appropriate gear motor is therefore not a trivial task; it involves considering numerous factors linked to the robot's specific application. Increasingly, robotic applications are demanding smaller, lighter, and more energy-efficient gear motors, further driving innovation within the industry.

Choosing the right gear motor isn't a one-size-fits-all endeavor. Here's a breakdown of the crucial selection points to consider:

1. Torque Requirements: This is arguably the most important factor. Torque is the rotational force needed to perform a specific task. Robotics applications vary vastly; a robot designed to pick up lightweight objects will require significantly less torque than one tasked with moving heavy materials. Always perform a detailed load analysis to accurately determine the required torque, considering inertia, friction, and any potential overload scenarios. Units are typically measured in Newton-meters (Nm) or inch-pounds (in-lb). Failing to account for sufficient torque will result in motor stalling, system failure, and potential damage.

2. Speed Requirements: The desired speed of the robot's joints or actuators is another critical consideration. Speed is usually measured in Revolutions Per Minute (RPM). High-speed applications, like robotic arms performing intricate welding tasks, demand gear motors with higher RPMs. Conversely, slower, more controlled movements, such as those found in medical robots, necessitate lower RPMs. Precise speed control is often achieved using encoders and sophisticated control algorithms.

3. Gear Ratio: The gear ratio determines the trade-off between torque and speed. A higher gear ratio provides increased torque at the expense of reduced speed, and vice versa. Choosing the optimal gear ratio involves balancing these trade-offs to meet the specific requirements of the robotic application. For example, a robot needing to lift a heavy object with slow, deliberate movements will need a high gear ratio.

4. Motor Type: Several motor types are available, each with its own advantages and disadvantages. * DC Motors: Simple, inexpensive, and offer good speed control. * AC Motors: Robust and efficient, suitable for high-power applications. * Brushless DC (BLDC) Motors: Highly efficient, long lifespan, and excellent torque-to-weight ratio – increasingly popular in modern robotics. * Stepper Motors: Offer precise positioning, ideal for applications requiring accurate and repeatable movements.

5. Size and Weight: In robotics, especially in mobile robots and collaborative robots (cobots), size and weight are often significant constraints. Compact and lightweight gear motors are becoming increasingly important. Miniaturization efforts are a key driver of innovation in this area.

6. Efficiency: Energy efficiency is crucial, not only for reducing operating costs but also for extending battery life in mobile robots. BLDC motors generally offer the highest efficiency.

7. Environmental Considerations: Robots often operate in harsh environments, such as dusty, humid, or corrosive settings. Select a gear motor designed to withstand these conditions. Consider IP (Ingress Protection) ratings to assess the motor's resistance to dust and water ingress.

8. Control Interface: The gear motor's control interface – whether it's analog, digital, or a serial communication protocol – must be compatible with the robot's controller. Popular protocols include CAN bus, Ethernet, and Modbus.

Selecting the right gear motor involves some calculations. Here's a simplified overview:

1. Torque Calculation:

Gear Ratio = T<sub>out</sub> / T<sub>motor</sub>. Select parameters that fit the optimal application.2. Speed Calculation:

Gear Ratio = Motor RPM / Output RPM. This allows you to select the appropriate motor and gear ratio to achieve the desired output speed.3. Power Calculation:

P<sub>out</sub> = T<sub>out</sub> * RPM. This is the power the gear motor needs to deliver to the application.P<sub>motor</sub> = P<sub>out</sub> / Efficiency. Ensure that the motor's power rating exceeds the required power.Current trends in robotics are reshaping gear motor demands:

1. Collaborative Robotics (Cobots): Cobots, designed to work alongside humans, often require gear motors with enhanced safety features, such as rounded edges and reduced noise levels. Lightweight and compact gear motors are also crucial for cobot applications.

2. Edge Computing: The rise of edge computing is driving the need for more powerful and autonomous robots. This, in turn, requires gear motors that can deliver higher torque and precision.

3. AI-Powered Robots: AI algorithms often demand faster and more precise movements. Gear motors with high-speed and low-latency control are essential for these applications. The increasing use of reinforcement learning in robotics also demands reliable and consistent performance from the gear motors.

4. Soft Robotics: Soft robots, employing flexible materials, pose challenges for traditional gear motors. Research is focused on developing more adaptable and compliant gear motor designs for these applications.

Selecting gear motors for robotics applications is a multifaceted process requiring careful consideration of torque, speed, gear ratio, motor type, size, weight, efficiency and environmental conditions. Using the provided calculation methods, engineers and roboticists can accurately assess the needs of their applications and choose the optimal gear motor. The trends of collaborative robotics, edge computing, AI-powered robots and soft robotics are directly influencing gear motor requirements, urging manufacturers to innovate towards more compact, efficient, safe and adaptable designs. As robotics continues to evolve, the demand for high-performance and reliable gear motors will only intensify, making this selection process a critical area of focus for the entire industry. MES-Drive is committed to providing a range of high-quality gear motors that meet the evolving needs of the robotics market, supporting innovation and driving progress in this exciting field. The increasing sophistication of robotic systems means that efficient and precisely controlled motion – delivered by meticulously selected gear motors – is not just desirable, but essential for future success.

Leave A Reply

Your email address will not be published. Required fiels are marked