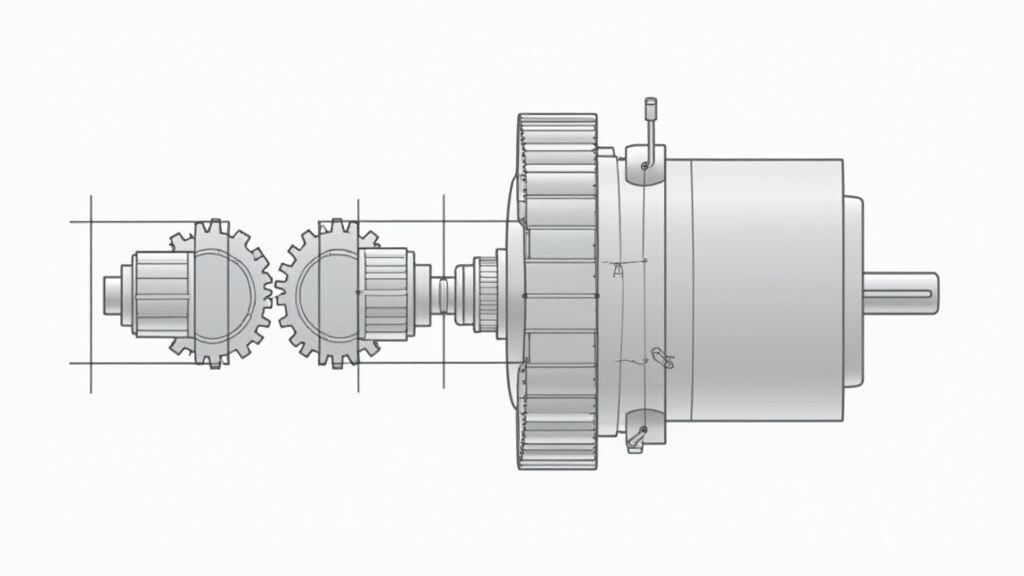

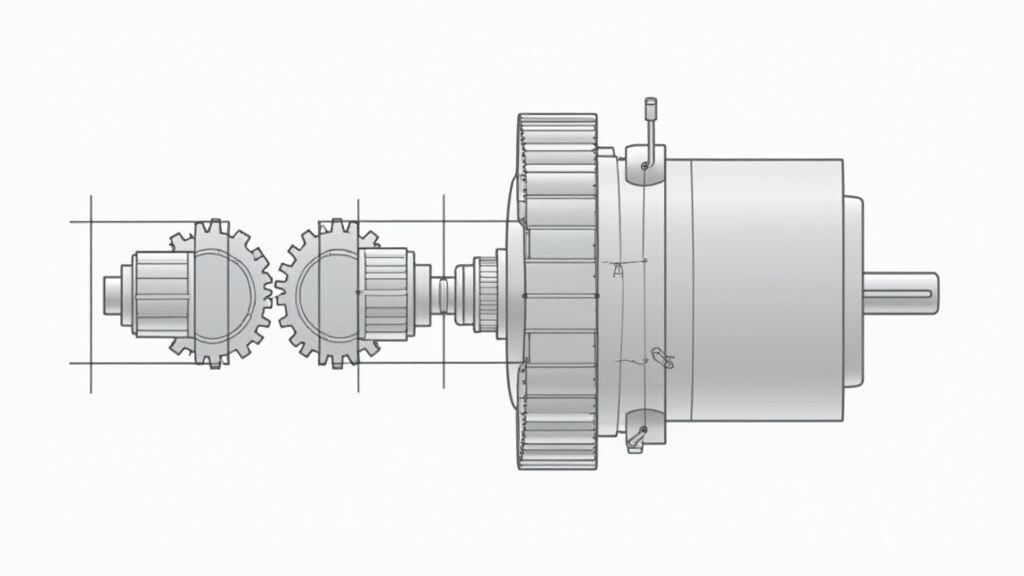

The medical equipment industry is a rapidly evolving sector, driven by advancements in healthcare technology and a growing demand for precision, reliability, and safety. At the heart of many medical devices lies the DC gear motor, a crucial component responsible for converting electrical energy into mechanical motion with controlled speed and torque. Choosing the right DC gear motor is paramount for ensuring the performance, longevity, and safety of these sensitive instruments. This article delves into the critical selection points and calculation methods for DC gear motor selection specifically tailored for the demanding requirements of medical equipment, highlighting considerations relevant to current industry trends like remote patient monitoring and AI-assisted diagnostics.

Unlike industrial applications, medical equipment operates under stringent regulations and faces heightened safety concerns. DC gear motors intended for medical use must meet rigorous standards outlined by organizations like the FDA (Food and Drug Administration) and IEC (International Electrotechnical Commission). These standards encompass aspects like electromagnetic compatibility (EMC), biocompatibility, and electrical safety. Beyond compliance, medical applications often demand exceptionally precise control, quiet operation, and minimal vibration to avoid interfering with sensitive measurements or patient comfort. Furthermore, long operational lifespans and high reliability are essential to minimize downtime and ensure uninterrupted patient care. The rise of connected medical devices for remote patient monitoring, fueled by the increasing adoption of IoT (Internet of Things) technologies, further necessitates robust and dependable motor performance.

Selecting the correct DC gear motor requires careful consideration of several factors:

Torque Requirements: This is arguably the most crucial factor. Medical equipment necessitates precise force application. Consider the peak torque, continuous torque, and starting torque required for the application. For example, infusion pumps need sufficient torque to precisely control fluid flow, while surgical robots require high torque for intricate movements. Datasheets provide information about stall torque and rated torque - the rated torque is the maximum torque the motor can consistently produce without overheating. Ensure the selected motor consistently exceeds the highest torque demand within the operating range. Oversizing slightly is often preferable to under-sizing, guaranteeing reliable performance.

Speed Requirements: The output speed dictates the rate of motion in the medical device. Different applications have varying speed requirements. Infusion pumps may require very low speeds for precise drug delivery, while diagnostic equipment like ultrasound machines might require higher speeds for image scanning. The gear ratio significantly influences the output speed; a higher gear ratio results in lower speed but higher torque, and vice versa. Accurate speed calculation is essential to ensure the device functions correctly.

Voltage and Current: The motor's voltage and current rating must be compatible with the power supply of the medical device. Ensure proper voltage regulation and current limiting mechanisms are implemented to protect the motor from overvoltage or overcurrent conditions. Voltage fluctuations are a common issue in medical settings, so a motor with a wide operating voltage range can be beneficial.

Size and Weight: In many medical devices, space is limited, and weight is a critical concern. Select a motor that is compact and lightweight while still meeting performance requirements. Miniaturization trends in medical devices are driving the demand for smaller, more efficient motors.

Noise and Vibration: Medical devices must operate silently to avoid disturbing patients or interfering with sensitive measurements. Look for motors designed for low noise and vibration, such as those with specialized bearing designs or damping mechanisms. This is especially critical for bedside monitoring systems and patient-facing equipment.

Environmental Conditions: Medical equipment often operates in environments with varying temperatures, humidity, and dust levels. Ensure the motor is rated for the specific environmental conditions of its intended use. IP (Ingress Protection) ratings provide a measure of the motor's resistance to dust and water ingress.

Safety and Compliance: The motor must meet all relevant safety standards, including those related to electromagnetic compatibility (EMC) and electrical safety. Look for motors that are certified to IEC 60601-1, the international standard for safety of electrical medical equipment. Biocompatibility is essential if the motor or any of its components come into contact with patients.

Several calculations are vital to ensure motor selection accuracy:

Torque Calculation: This involves determining the required torque based on the load being driven, considering factors such as friction, inertia, and acceleration/deceleration rates. The formula is simple:

*Torque (T) = Moment of Inertia (J) * Angular Acceleration (α)*

where:

It's recommended to add a safety factor (e.g., 20-30%) to the calculated torque to account for unforeseen loads or operating conditions.

Speed Reduction Calculation: This calculates the required gear ratio based on the desired output speed and the motor's input speed.

Gear Ratio (GR) = Input Speed (Nin) / Output Speed (Nout)

Selecting an appropriate gear ratio is crucial for achieving the desired torque and speed characteristics.

Power Calculation: Determine the required power based on the required torque and speed.

*Power (P) = Torque (T) * Angular Velocity (ω)*

where:

Consider efficiency losses in the gear system; power loss is always present.

MES-Drive offers a comprehensive range of high-quality DC gear motors specifically designed for the medical equipment industry. Our motors are manufactured to meet stringent quality standards and are compliant with relevant safety regulations. We offer a variety of sizes, power ratings, and gear ratios to meet the diverse needs of medical device manufacturers. Furthermore, MES-Drive invests heavily in research and development to provide innovative motor solutions tailored for emerging medical technology trends. Our motors incorporate advanced features such as low noise designs, high efficiency, and extended lifespans, ensuring optimal performance and reliability.

The confluence of remote patient monitoring, AI-assisted diagnostics, and miniaturized medical devices is reshaping the medical equipment landscape. This trend demands motors that are not only precise and reliable but also energy-efficient and compact. Furthermore, the increasing focus on cybersecurity necessitates motor designs that are resistant to electromagnetic interference and potential hacking attempts. MES-Drive is actively developing motors with enhanced cybersecurity features and improved energy efficiency to meet these evolving demands. The integration of smart motor control systems, leveraging IoT connectivity, also promises to unlock new capabilities for remote monitoring, diagnostics, and predictive maintenance within medical devices.

Selecting the appropriate DC gear motor for medical equipment is a critical decision that significantly impacts device performance, reliability, and patient safety. By carefully considering the factors outlined in this article and employing accurate calculation methods, medical device manufacturers can ensure they choose a motor that meets their specific needs. As the medical equipment industry continues to innovate and embrace emerging technologies like AI and IoT, the demand for high-performance, reliable DC gear motors will only increase. MES-Drive is well-positioned to be a key partner in this evolution, offering innovative solutions that empower medical device manufacturers to create the next generation of healthcare technologies. The increasing adoption of connected medical devices offers vast potential, and robust motor technology is the foundation of this advancement.

Leave A Reply

Your email address will not be published. Required fiels are marked