In today's rapidly evolving manufacturing landscape, automated production lines are becoming increasingly prevalent. These lines demand precision, reliability, and efficiency – all of which hinge significantly on the selection of appropriate gear motors. Choosing the right gear motor isn't just about power; it's a strategic decision that impacts overall line performance, maintenance costs, and production throughput. This article delves into the crucial selection points and calculation methods for gear motor selection, specifically tailored from the perspective of an automated production line. We will also touch upon the growing importance of energy efficiency and predictive maintenance in modern manufacturing, and how advanced solutions from companies like MES-Drive can address these trends.

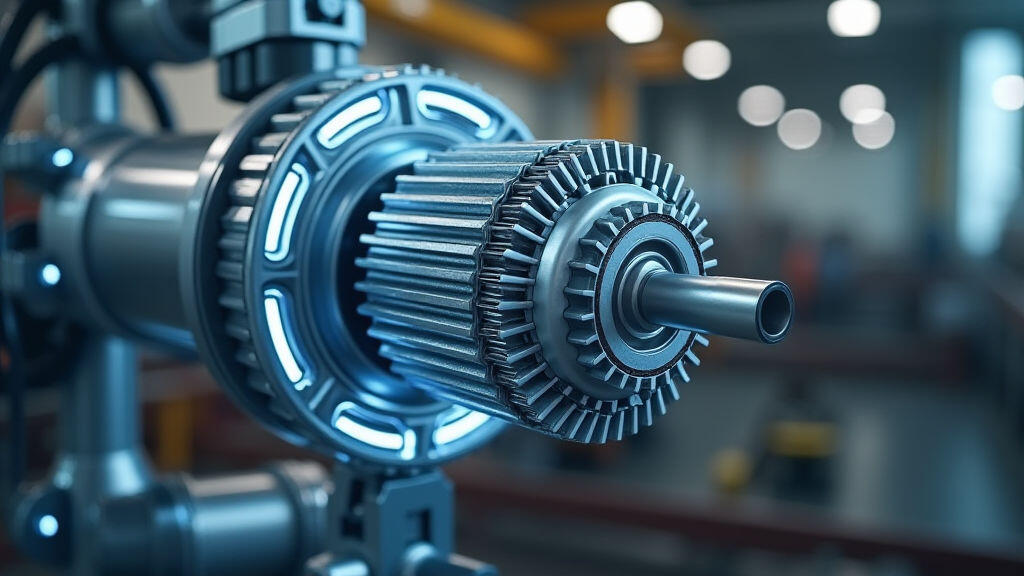

Gear motors are the workhorses of automated production lines. They bridge the gap between the motor's rotational speed and the required output speed and torque for various processes such as conveying, packaging, material handling, and robotic actuation. Without a properly selected gear motor, a production line can experience bottlenecks, reduced accuracy, increased wear and tear, and ultimately, significant financial losses. The constant demand for higher speeds, heavier loads, and more complex movements means gear motor selection demands a detailed and systematic approach.

Several factors must be considered when selecting a gear motor for an automated production line. A failure to adequately address these criteria can lead to costly downtime and operational inefficiencies. Here's a thorough breakdown:

Accurate torque and power calculations are foundational to successful gear motor selection. Here are some widely used methods:

1. Static Load Calculation:

This method is used to determine the torque required to overcome static friction and hold a load at rest.

Torque (Nm) = (Load (N) * Distance to Center of Rotation (m))2. Dynamic Load Calculation:

This method considers the torque required to accelerate, decelerate, and maintain motion with a dynamic load. It involves calculating the inertia of the load and the required acceleration/deceleration rates.

Torque (Nm) = (Moment of Inertia (kg.m²) * Angular Acceleration (rad/s²)) (for acceleration)Torque (Nm) = (Moment of Inertia (kg.m²) * Angular Deceleration (rad/s²)) (for deceleration)3. Efficiency Factor:

To account for energy losses due to friction, a gear efficiency factor is applied:

Output Power (Watts) = (Motor Power (Watts) * Gear Efficiency)Gear efficiency typically ranges from 70% to 95%, depending on the gear type and design.

4. Safety Factor:

A safety factor is essential to ensure the gear motor can handle unexpected loads and extend its lifespan. A common safety factor is 1.5 to 2.0.

Modern manufacturing is increasingly focused on energy efficiency and minimizing downtime. Gear motors playing a pivotal role in these initiatives. Manufacturers are actively seeking gear motors with IE3 or IE4 efficiency ratings to reduce energy consumption. Furthermore, the adoption of Internet of Things (IoT) and Industry 4.0 technologies is driving the demand for predictive maintenance. Advanced sensors and data analytics can monitor gear motor performance, identify potential issues early, and prevent costly breakdowns. MES-Drive offers gear motors designed with optimized efficiency and connectivity, paving the way for proactive maintenance strategies.

companies like MES-Drive are at the forefront of developing high-performance, energy-efficient gear motors tailored for automated production lines. Their product range encompasses a wide variety of gear types, power ratings, and mounting options, ensuring compatibility with diverse application requirements. MES-Drive's commitment to innovation extends to incorporating smart features like remote monitoring and diagnostics, facilitating predictive maintenance and enhancing operational efficiency. Their gear motors are designed for optimal performance, reliability, and longevity, ultimately contributing to higher production yields and reduced operating costs.

Choosing the right gear motor is a critical investment for any automated production line. By meticulously considering the selection points, applying accurate calculation methods, and embracing energy-efficient solutions, manufacturers can optimize line performance, minimize downtime, and enhance overall profitability. In the context of the increasing demand for sustainable manufacturing practices and the rapid advancements in Industry 4.0, gear motors like those offered by MES-Drive are poised to play an even more vital role. The integration of smart features, predictive maintenance capabilities, and optimized energy efficiency will be key to unlocking the full potential of automated production lines in the years to come. Addressing these requirements will enable manufacturers to remain competitive and thrive in the evolving landscape of modern manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked