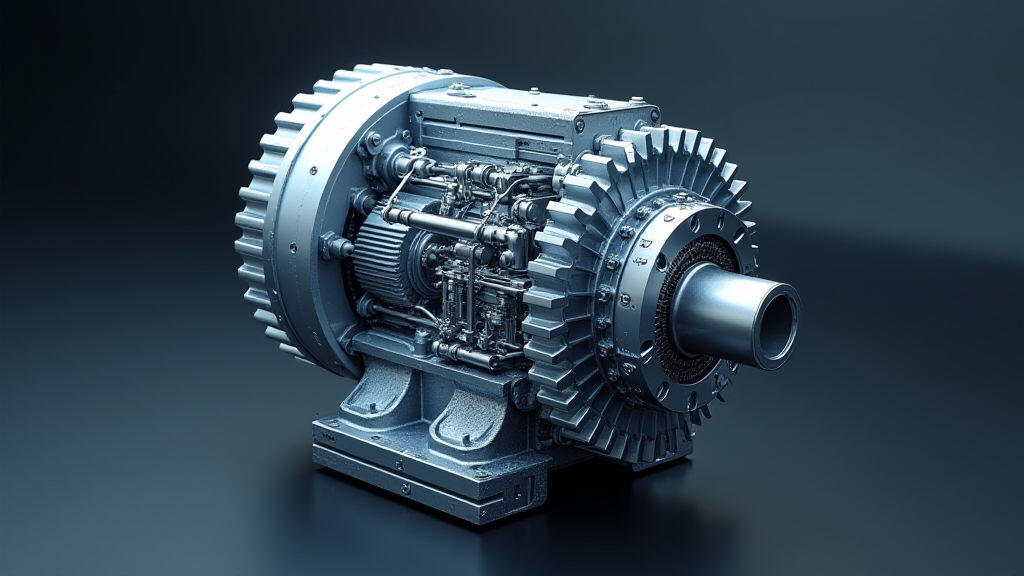

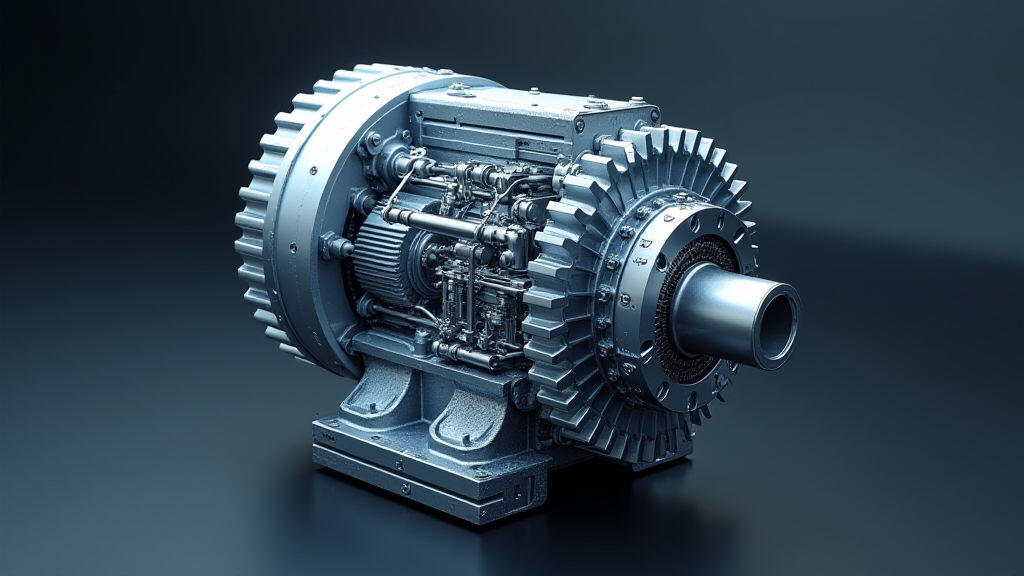

The global industrial landscape is undergoing a rapid transformation, driven by advancements in automation, digitalization, and a growing emphasis on energy efficiency. At the heart of many modern industrial applications are gear motors – robust, reliable, and versatile power transmission devices. For gear motor manufacturers, understanding the evolving needs of the market, optimizing production processes, and ensuring product quality are paramount. This article delves into critical selection points and calculation methods for gear motor manufacturers, viewed through the lens of manufacturing efficiency, cost-effectiveness, and future-proofing. We’ll also touch upon how AI and Industry 4.0 trends are impacting the industry.

The demand for gear motors is consistently rising, fueled by several key trends:

These trends present significant challenges for manufacturers. Maintaining quality under pressure, optimizing production costs, and adapting to rapidly changing specifications require a holistic approach to engineering, manufacturing, and supply chain management.

For gear motor manufacturers, selecting the right materials, processes, and technologies is crucial for staying competitive. Here are some key considerations:

1. Gear Material Selection:

2. Gear Type:

3. Lubrication:

Accurate calculations are essential for optimizing gear motor performance, efficiency, and reliability. Here’s an overview of key calculation methods:

1. Torque and Speed Calculation:

The fundamental equation relates torque (T), speed (N), and power (P): P = T * N. Gear ratios are crucial for adjusting torque and speed. Manufacturers utilize software tools (e.g., finite element analysis, dynamic simulation) to accurately predict torque, speed, and power characteristics under various load conditions.

2. Efficiency Calculation:

Efficiency (η) is a critical performance metric. It’s calculated as η = (Output Power / Input Power) * 100%. Manufacturers use advanced modeling techniques, considering frictional losses due to gear mesh, bearing friction, and windage, to accurately estimate efficiency. Improving efficiency is a key focus for manufacturers in light of rising energy costs and environmental regulations.

3. Load Analysis:

Detailed load analysis is vital for selecting appropriate gear materials and designs. Manufacturers use FEM (Finite Element Method) analysis to simulate stress and strain distribution within the gears under various load scenarios. This helps to identify potential failure points and optimize gear geometry for maximum strength and fatigue resistance.

4. Thermal Analysis:

Gear motors generate heat due to friction. Thermal analysis is crucial for ensuring that the motor operates within safe temperature limits. Manufacturers use computational fluid dynamics (CFD) to simulate heat transfer and optimize cooling systems.

Artificial intelligence (AI) and Industry 4.0 are revolutionizing gear motor manufacturing. Here's how:

MES-Drive, for example, is actively exploring the use of AI for predictive maintenance and process optimization, offering its clients a competitive edge.

The gear motor market is poised for continued growth, driven by evolving industry needs. To succeed, gear motor manufacturers must embrace innovation, optimize manufacturing processes, and leverage emerging technologies like AI. By focusing on material selection, gear type optimization, efficient lubrication, and accurate performance calculations, manufacturers can deliver high-quality, reliable, and energy-efficient gear motor solutions. Furthermore, integrating AI and Industry 4.0 principles into their operations will be critical for maintaining competitiveness and adapting to the rapidly changing industrial landscape. The ability to personalize gear motors, combined with increased automation and predictive maintenance, positions gear motor manufacturers for long-term success and plays a critical role in enabling a more sustainable and efficient future.

Leave A Reply

Your email address will not be published. Required fiels are marked