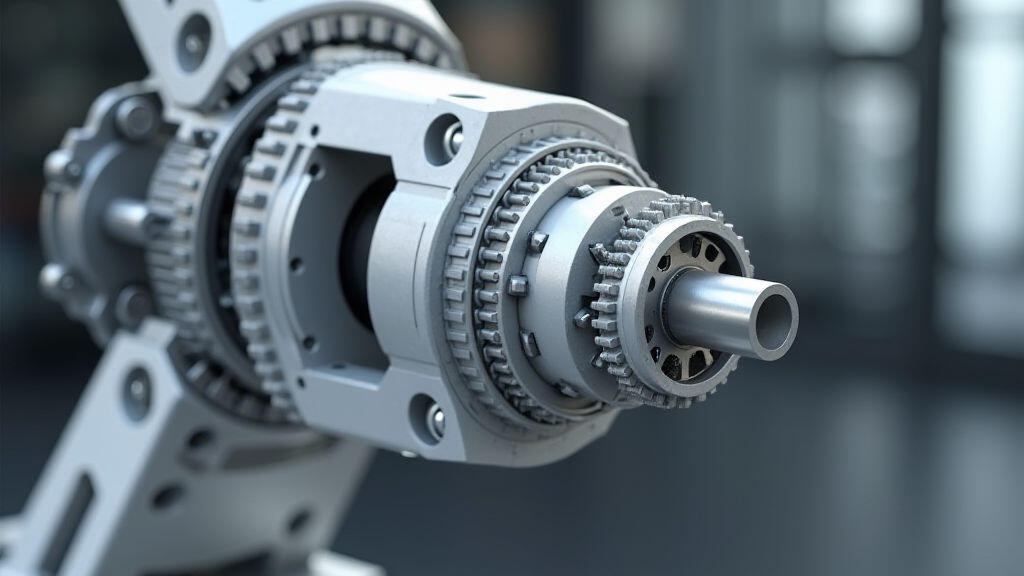

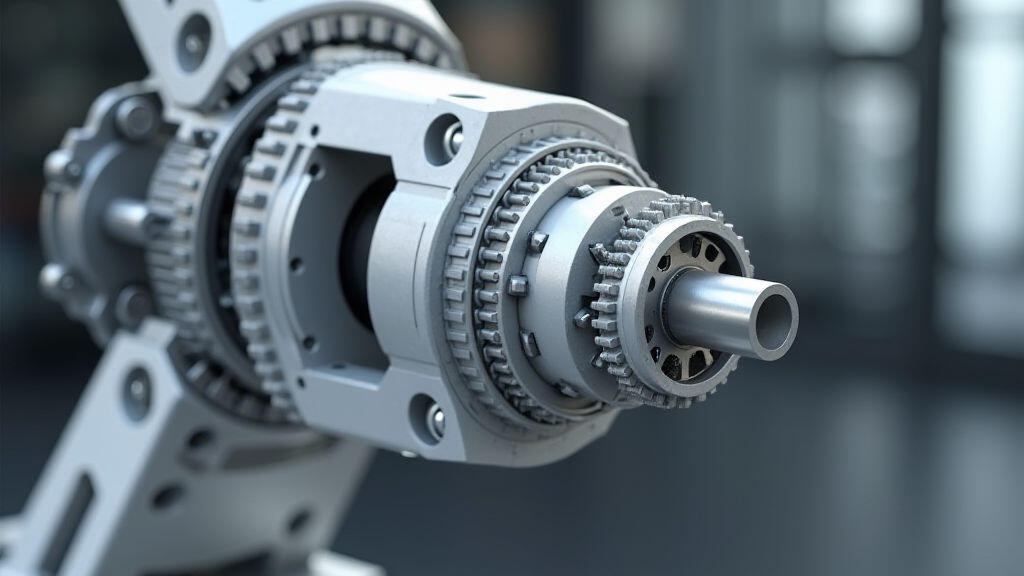

The automotive industry is undergoing a radical transformation. Driven by the relentless push for electric vehicles (EVs), autonomous driving, and advanced driver-assistance systems (ADAS), manufacturers are constantly seeking ways to improve efficiency, precision, and reliability in their production processes. A critical component in many automotive parts equipment is the gear motor – a combination of a motor and a gearbox that provides enhanced torque and speed reduction, making it vital for tasks ranging from stamping and forging to assembly and testing. Specifically, right-angle gear motors are increasingly popular due to their compact size and ability to transmit power at a 90-degree angle, offering significant advantages in space-constrained automotive manufacturing environments. This article explores effective right-angle gear motor configuration strategies in the context of upgrading automotive parts equipment, focusing on current trends and the role of innovative solutions like those offered by MES-Drive.

The Evolving Demands of Automotive Manufacturing

The transition to EVs and increasingly complex vehicles has dramatically altered the requirements for automotive parts equipment. Traditional hydraulic and pneumatic systems are gradually being replaced with electric solutions for improved energy efficiency, reduced emissions, and enhanced control. This shift creates a surge in demand for high-performance gear motors capable of handling higher torques and operating at variable speeds. Furthermore, the rise of ADAS necessitates increased accuracy and precision in automated assembly and testing processes. This translates into a need for gear motors with tighter tolerances, smoother operation, and sophisticated control capabilities. The focus has moved beyond simply providing rotational power to delivering precise, controlled motion, a trend heavily influenced by advancements in AI and machine learning.

Why Right-Angle Gear Motors? A Strategic Advantage

Right-angle gear motors are particularly well-suited for modern automotive equipment due to several key advantages:

]

] Configuration Strategies for Enhanced Performance

Successful implementation of right-angle gear motors in automotive equipment necessitates careful consideration of configuration strategies. Here are a few key areas:

Gear Ratio Optimization: The choice of gear ratio is paramount. A higher gear ratio provides greater torque but reduces speed, while a lower gear ratio offers higher speed with less torque. Selection should align precisely with the equipment's specific power and speed requirements. Simulation tools are increasingly employed to optimize gear ratios based on application demands, minimizing energy consumption and maximizing efficiency.

Gearbox Type Selection: Different gearbox types – helical, bevel-helical, worm, and planetary – offer varying performance characteristics.

Motor Selection: The motor must be compatible with the gearbox and provide the required power output and speed. Brushless DC (BLDC) motors are gaining popularity due to their high efficiency, long lifespan, and precise control capabilities. AC induction motors remain a viable option for more cost-sensitive applications. Considerations include motor power, voltage, and control algorithms.

Cooling Systems: High-power applications often require sophisticated cooling systems to prevent overheating and ensure reliable operation. Options include air cooling, liquid cooling, and oil cooling. The choice depends on the motor's power rating and operating environment. Thermal management is crucial for maintaining long-term performance and preventing premature failure.

Integrated Control Systems: Modern automotive equipment relies on sophisticated control systems for precise motion control and feedback. Integrating the right-angle gear motor with a closed-loop control system allows for dynamic adjustment of speed, torque, and position, optimizing performance and enabling advanced functionalities like adaptive control and predictive maintenance.

MES-Drive: Leading the Way in Right-Angle Gear Motor Solutions

MES-Drive is at the forefront of developing and implementing cutting-edge right-angle gear motor solutions for the automotive industry. Their advanced gear designs, coupled with high-performance motors and sophisticated control systems, provide unparalleled performance, efficiency, and reliability. MES-Drive's solutions are tailored to meet the evolving demands of modern automotive manufacturing, offering custom configurations and integrated control systems.

[  ]

]

MES-Drive's commitment to innovation extends to the integration of AI-powered predictive maintenance systems. By analyzing real-time data from motor sensors, these systems can identify potential failures before they occur, minimizing downtime and maximizing equipment lifespan. This aligns perfectly with the industry's push for greater operational efficiency and reduced maintenance costs.

Conclusion: Powering the Future of Automotive Manufacturing

Right-angle gear motors are no longer just a simple power transmission component; they are integral to the performance, efficiency, and reliability of modern automotive parts equipment. The strategic configuration of these motors, encompassing gear ratio optimization, gearbox type selection, and integrated control systems, is essential for meeting the evolving demands of the industry.

As the automotive sector continues to embrace electrification, automation, and advanced driver-assistance systems, the demand for high-performance, precision-engineered right-angle gear motor solutions will only increase. MES-Drive, with its focus on innovation and customer-centric solutions, is well-positioned to lead the way in powering the future of automotive manufacturing. The ongoing trends in automotive technology, particularly the rise of AI-driven predictive maintenance, create exciting opportunities for further advancements in right-angle gear motor technology, promising even greater efficiency, reliability, and performance in the years to come.

Leave A Reply

Your email address will not be published. Required fiels are marked