Packaging Equipment: The Key Role of What a Gear Motor Is in Practical Applications

In today’s fast-paced world, efficient and reliable packaging is paramount. From food and beverage to pharmaceuticals and consumer goods, the demands on packaging machinery are constantly evolving. This evolution necessitates robust, precise, and energy-efficient components. At the heart of many packaging applications lies a critical piece of technology: the gear motor. While often unseen, gear motors are the unsung heroes driving a wide range of processes, ensuring smooth operation and contributing significantly to the overall efficiency of the entire packaging line. This article delves into the key role of gear motors in packaging equipment, exploring their functionality, benefits, common applications, and future trends, particularly in the context of the increasing focus on sustainability and automation.

Understanding Gear Motors: Principles and Types

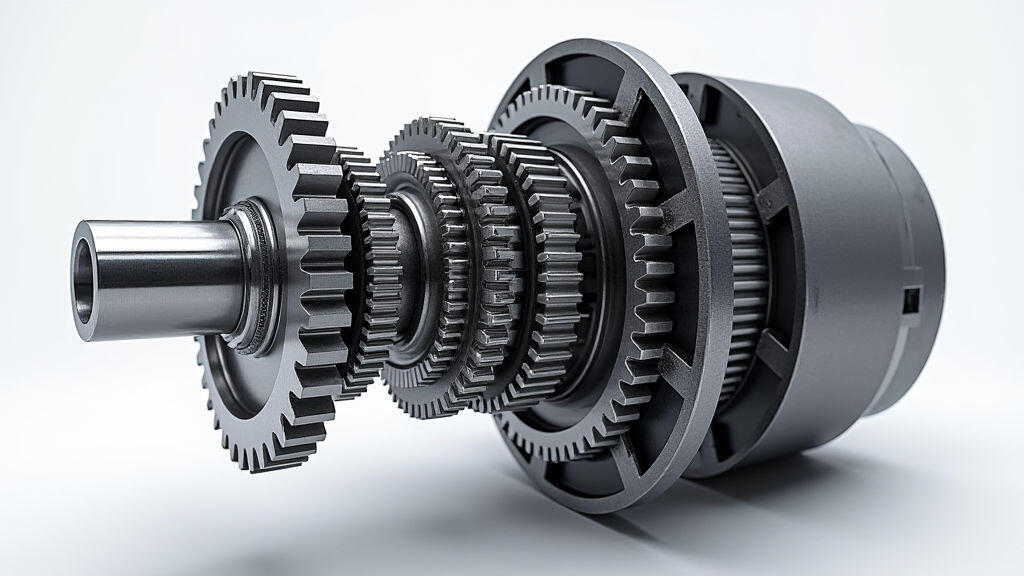

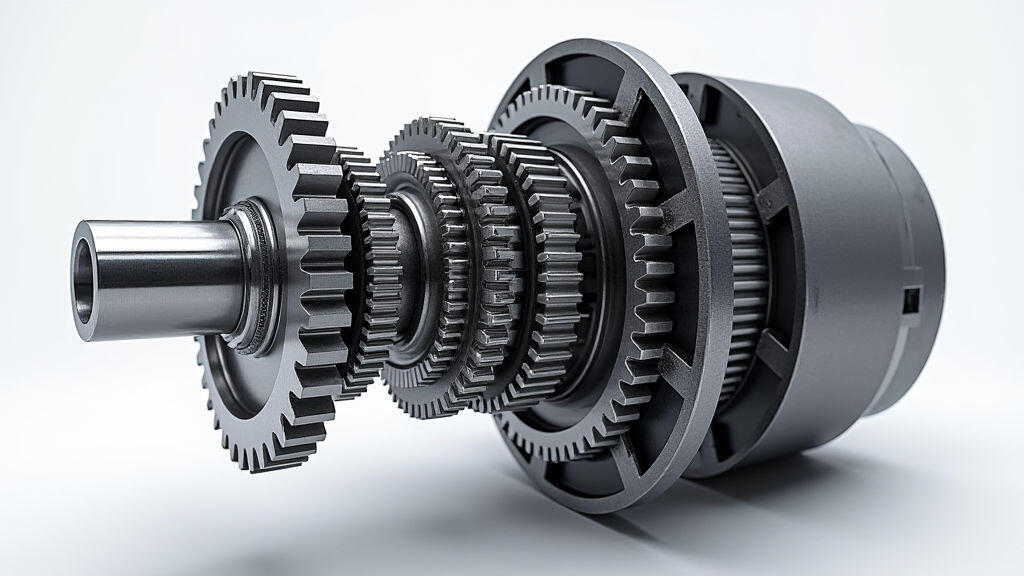

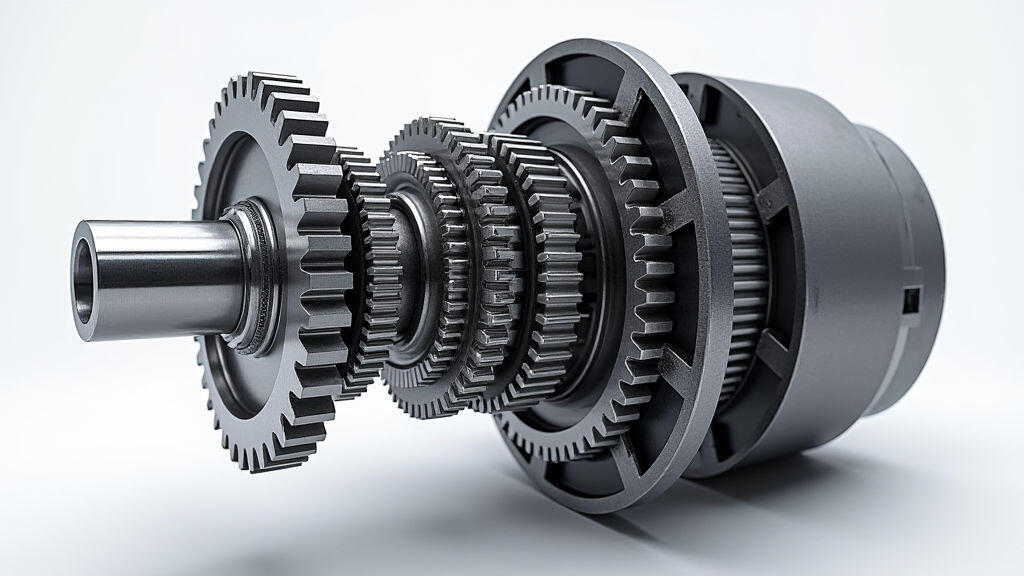

A gear motor is essentially an electric motor coupled with a gearbox. The motor provides the rotational power, while the gearbox modifies this power – primarily by reducing the speed and increasing the torque. This combination offers a powerful solution for applications requiring precise control and high force output. The gearbox uses a set of gears to achieve the desired speed and torque ratio.

There are several types of gear motors, each with its own advantages and disadvantages:

- Spur Gear Motors: These are the simplest and most common type. Gears mesh parallel to the shaft, making them relatively inexpensive and efficient. However, they can be noisy at high speeds.

- Helical Gear Motors: Offering smoother and quieter operation than spur gears due to the angled gear teeth, helical gear motors are suitable for applications demanding low noise. They typically handle higher loads than spur gears.

- Worm Gear Motors: These provide high reduction ratios in a compact package. They’re self-locking, meaning they can resist back-driving, a crucial feature for safety in certain packaging applications. However, they are less efficient than other gear types.

- Planetary Gear Motors: They offer a compact design and high torque density, making them a good solution where space is limited. Their efficiency is generally good.

The Vital Role in Packaging Processes

Gear motors are integral to a vast array of packaging processes. Let’s examine some key applications:

- Conveyor Systems: From basic transport to sophisticated automated systems, gear motors are the driving force behind conveyor belts that move products through various stages of the packaging line. Precision speed control provided by gear motors ensures consistent product flow.

- Filling Machines: Accurate and consistent filling is crucial in many packaging applications. Gear motors power the mechanisms that control the dispensing of liquids, powders, and granular materials, ensuring product weight and volume accuracy.

- Forming and Shaping: Many packaging types involve forming materials into specific shapes, such as pouches, boxes, or bottles. Gear motors drive the mechanisms that perform these shaping tasks, often requiring precise force and controlled movement.

- Sealing and Closing: Reliable sealing is essential to maintain product integrity and prevent contamination. Gear motors power sealing jaws, heat seals, and other closing mechanisms, guaranteeing airtight or watertight closures. The strength and repeatability are crucial.

- Labeling and Coding: Automatic labeling and coding machines rely on gear motors for consistent positioning and movement of labels and ink applicators. Accuracy in these processes is critical for branding and regulatory compliance.

- Wrapping Machines: Gear motors are central in rotary and continuous wrapping machines, ensuring the precise movement of film or foil around products to create secure and attractive packaging.

Benefits of Using Gear Motors in Packaging

The use of gear motors in packaging equipment provides numerous advantages:

- High Torque: Gear motors excel at delivering high torque, enabling them to overcome significant resistance and power heavy packaging mechanisms.

- Precise Control: The gear reduction mechanism allows for precise speed and torque control, essential for intricate packaging processes. This precision helps minimize waste and ensures product quality.

- Compact Size: Modern gear motor designs are increasingly compact, reducing the overall footprint of packaging equipment. This is particularly important in space-constrained environments.

- Reliability and Durability: Gear motors are known for their robust construction and long service life, capable of withstanding the demanding conditions of continuous packaging operations.

- Energy Efficiency: Advances in gear motor technology have significantly improved energy efficiency, reducing operating costs and minimizing environmental impact.

- Reduced Noise: Helical and planetary gear motors are designed to operate with reduced noise levels, creating a more comfortable working environment.

The Future of Gear Motors in Packaging: Automation and Sustainability

The packaging industry is undergoing a significant transformation, driven by the trends of automation and sustainability. These trends are fueling innovation in gear motor technology.

Automation: The increasing adoption of robots and automated systems in packaging lines requires gear motors that are highly precise, reliable, and controllable. The demand for closed-loop control systems, enabled by advanced motor control techniques, is growing rapidly.

Sustainability: The focus on reducing energy consumption and minimizing waste is driving the development of more energy-efficient gear motors. This includes the use of advanced materials, optimized gear designs, and regenerative braking systems to recapture energy during deceleration. The rise of electric vehicles and the push for greener manufacturing processes are directly impacting the design and adoption of more sustainable power solutions within packaging equipment. Furthermore, the trend towards recyclable and biodegradable packaging necessitates precise equipment to handle these new materials effectively.

MES-Drive is at the forefront of developing innovative gear motor solutions specifically tailored for the evolving needs of the packaging industry. Our commitment to quality, reliability, and energy efficiency ensures that our customers can optimize their packaging operations while minimizing their environmental footprint.

Conclusion

Gear motors are fundamental components in modern packaging equipment, playing a critical role in driving efficiency, precision, and reliability. As the packaging industry continues to embrace automation and sustainability, the demand for advanced gear motor technology will only increase. From advanced robotic systems to energy-efficient processes, gear motors are enabling innovation across the packaging value chain. MES-Drive is dedicated to meeting these challenges, developing solutions that empower packaging manufacturers to thrive in a dynamic and demanding marketplace. The future of packaging hinges on the continued advancements in technologies like gear motors, and we are proud to be leading the way.

Leave A Reply

Your email address will not be published. Required fiels are marked