Introduction

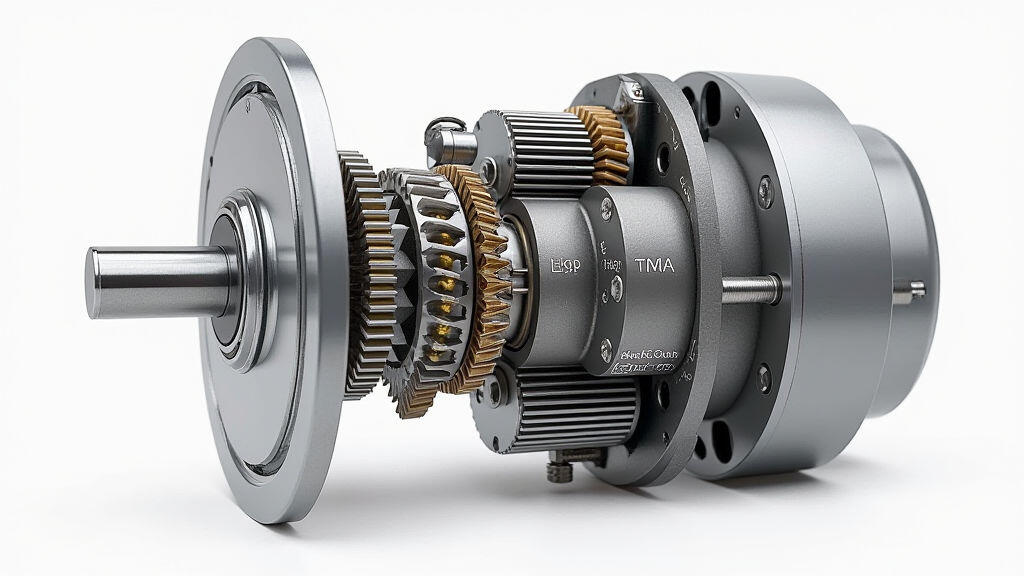

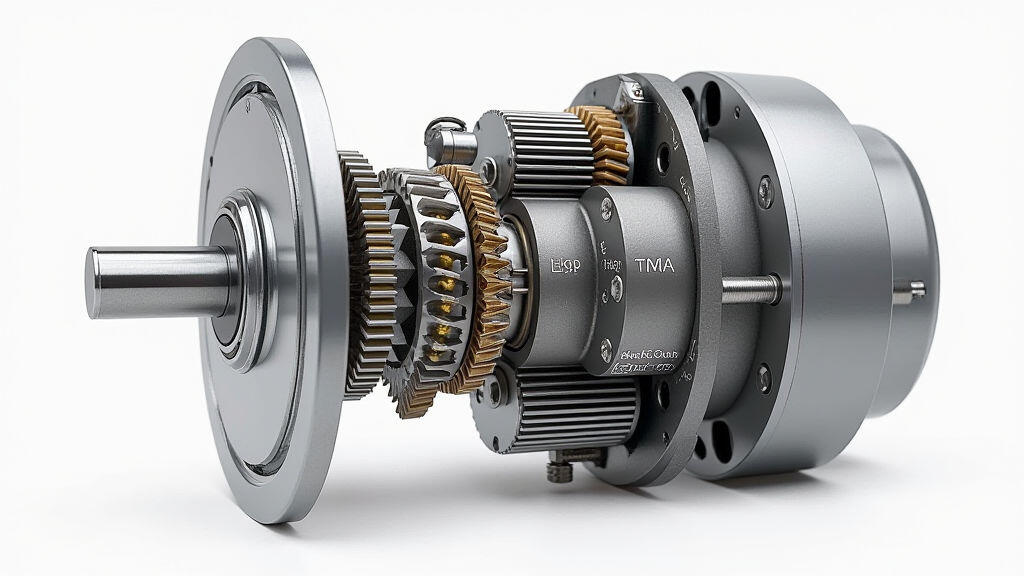

In the fast‑moving world of consumer goods and e‑commerce, packaging lines must deliver speed, reliability, and flexibility. One of the most powerful levers for modernizing these lines is the micro DC gear motor. These compact power units bring precise control, high torque, and low energy consumption to the heart of packaging equipment. This article explores how to configure micro DC gear motors effectively when upgrading packaging machines, breaking down key strategies, common pitfalls, and real‑world results.

Why Micro DC Gear Motors Matter

Traditional hydraulic or larger electric motors often occupy a large footprint and demand constant maintenance. In contrast, micro DC gear motors fit into tight spaces, reduce vibration, and offer programmable speed profiles. These features translate into faster change‑over between product lines, less downtime, and lower operational costs—critical advantages for manufacturers facing high competition and short product cycles.

Understanding the Packaging Equipment Landscape

Packaging systems can range from a simple pouch seal line to a sophisticated automated box‑assembly robot. Each application has distinct torque, speed, and positional accuracy requirements. Before any motor is selected, teams should map the mechanical load, identify critical motion segments (e.g., palletization, labeling, sealing), and quantify peak torque events such as start‑up and stop‑down. This groundwork informs the motor’s gearing, shaft design, and control strategy.

1. Selecting the Right Gear Ratio

One of the most fundamental decisions is the gear ratio, which balances torque against speed. An oversized ratio can overload the motor, while an undersized ratio leaves insufficient force for high‑load tasks. A practical rule of thumb is to match the motor’s no‑load speed to 120–150 % of the required cycle speed, then use the gear train to supply the necessary torque boost. Manufacturers often employ a two‑stage gear set: a primary reduction for bulk torque and a secondary fine‑tune for precision control.

2. Bearing Choices for Longevity

Micro motors rely on high‑precision bearings—silicone or magnetic bearing types are common for noise reduction and reliability. When upgrading, assess whether the existing bearing design can sustain the new motor’s radial loads. In many cases, swapping a stock ball bearing for a tapered roller bearing with a higher load rating significantly extends service life.

3. Motor Housing and Thermals

Packaging lines generate heat through both the environment and motor operation. A thermally‑managed housing—often aluminum with finned surfaces—helps dissipate heat. Upgrades should also consider venting and airflow around the motor to avoid overheating peaks during consecutive high‑speed cycles.

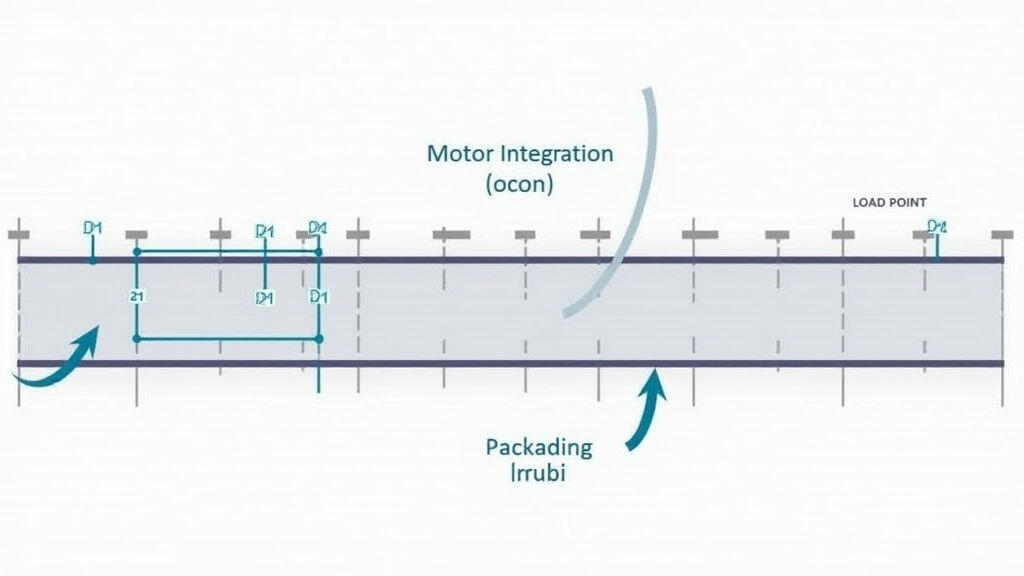

4. Integrated Controller and Feedback

Modern micro motors allow integration with PLCs or DCS via low‑voltage PWM. Embedding a Hall‑effect sensor or encoder provides real‑time feedback for closed‑loop control, ensuring positional accuracy on tasks like automated label application. For upgrading, add a compact motor driver that supports both forward/reverse operations and regenerative braking to recover energy during deceleration.

5. Cable Management & Safety

The smaller the motor, the more critical its cable routing. Plan for flexible, strain‑relieved cables that can withstand repeated flexing. Also, incorporate overcurrent protection, such as a fuse rated slightly above the motor’s peak current, to guard against supply surges.

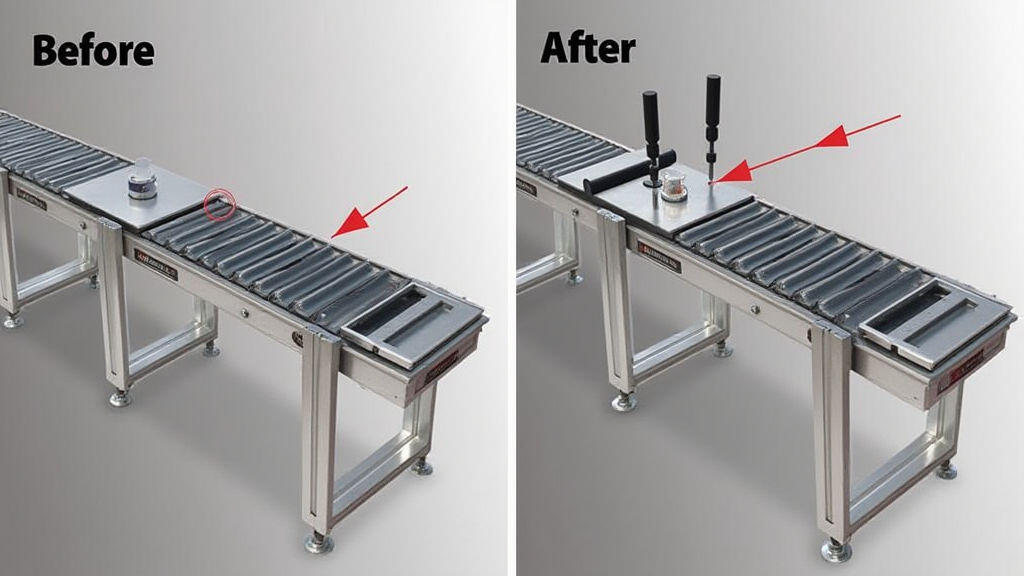

6. Modular Installation

Design the motor mounting as a plug‑and‑play module. By using standardized brackets and quick‑release fittings, technicians can swap motors or upgrade gearing without long shutdowns. This modularity is especially valuable in high‑throughput environments where a 4‑hour downtime kills revenue.

Case Study: Retrofitting a Box‑Sealing Line

A mid‑size manufacturer updated its box‑sealing line by replacing the legacy 90 V AC motor with a 48 V DC gear motor rated at 12 Nm and 1,200 RPM. The new motor, coupled with a 30:1 gear train, delivered the required 2,400 Nm peak torque for sealing heavy cardboard boxes. The integration also added a micro‑controller for dynamic speed tuning, reducing cycle time from 4.5 s to 3.2 s—an 29 % throughput increase. Energy consumption dropped by 18 % thanks to the DC motors’ higher efficiency.

Future Trends: IoT and Predictive Maintenance

The next wave of upgrades looks beyond motor selection to connectivity. Embedding IoT sensors—temperature, vibration, or current monitoring—into the motor module allows predictive maintenance. Manufacturers can schedule repairs before a bearing fails, avoiding catastrophic machine stoppage. In addition, AI algorithms can adjust gear ratios dynamically in response to real‑time loads, ensuring optimal torque distribution during varying production scenarios.

Conclusion

Micro DC gear motors are a game‑changer for packaging equipment upgrades. By carefully selecting gear ratios, bearings, and controllers, manufacturers can achieve higher speed, greater torque, and lower energy usage—all while retaining compact form factors that fit into existing line layouts. The modular, IoT‑ready designs we discuss today not only deliver immediate ROI but also position firms to adapt swiftly to tomorrow’s market demands. As packaging needs evolve toward sustainability and speed, the micro motor upgrade strategy will become a cornerstone of competitive capability.

Leave A Reply

Your email address will not be published. Required fiels are marked