Gear reducers are the unsung heroes of modern packaging lines. From automatic wrappers to high‑speed conveyors, they translate motor speed into precise torque and position, allowing operators to work with controlled force and accuracy. However, choosing the right reducer involves more than picking a model that fits a shaft. Packaging enterprises must balance performance, durability, cost, and integration to avoid costly downtime and wasted throughput. This article breaks down the essential parameters that should drive your selection process, framed in a practical, procurement‑friendly way.

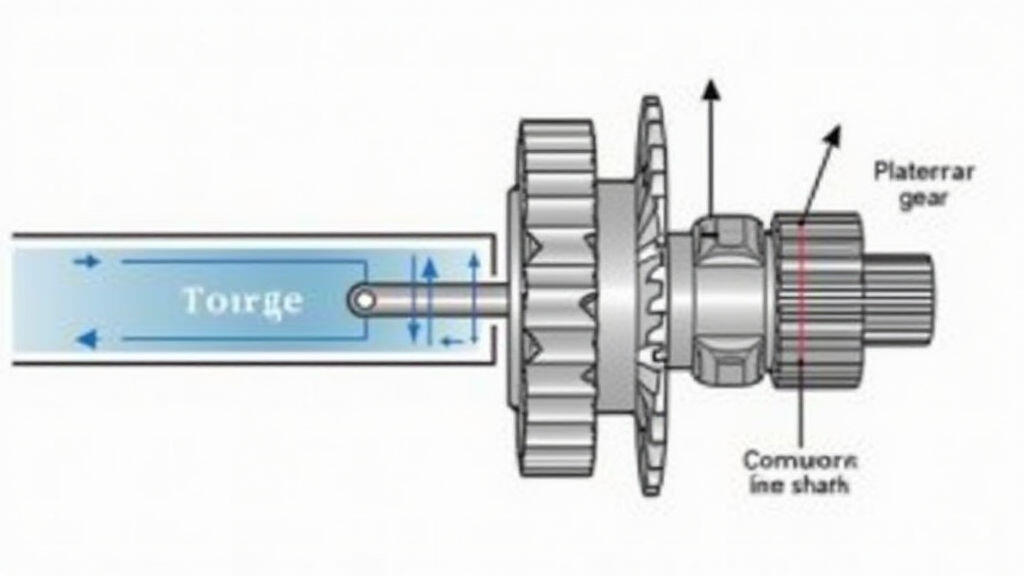

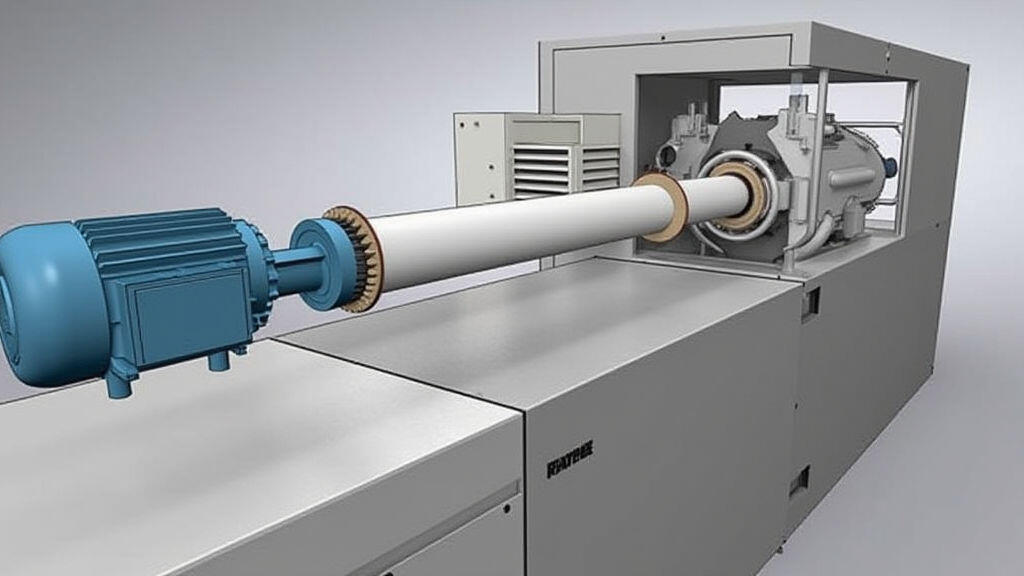

At its core, a gear reducer is a set of gears that reduces input speed while increasing torque. Most packaging machines use planetary, helical, or worm gear reductions, each with distinct advantages. Planetary gears offer unbeatable torque density and compactness – ideal for robots that pick and place cartons. Helical gears deliver high efficiency and low noise, suitable for continuous conveyor drives. Worm gears provide self‑locking capability, useful in operators that need to stop a line without a separate brake.

Before diving into parameters, keep in mind that the final choice depends on two primary factors: the input motor characteristics (speed, torque, and power) and the desired output (speed, load, and duty cycle).

Power transmission is a product of torque and speed. Packaging equipment often demands specific speed reductions, such as from a 3 kW motor at 3,000 rpm down to a conveyor belt running at 150 rpm. The gear ratio is the ratio of input to output speed; it also determines the output torque (higher ratios provide higher torque). When selecting a reducer, confirm that the ratio delivers the exact output speed while staying within the motor’s safe operating range.

Torque capacity is the maximum force the reducer can transfer without mechanical failure. It is crucial to evaluate the peak load of your packaging process—once the machine starts the load spikes dramatically due to inertia, then tapers to a steady state. Select a reducer rated well above this peak to maintain a safety margin (often 2×). Planetary reducers can offer up to 150% higher torque density than helical gears of the same size.

Efficient reducers save energy and reduce operating costs. For helical gears, efficiencies often exceed 95%; planetary units can reach 93‑95%. Noise is a more delicate issue in packaging lines that run continuously. Refined gear hobbing and surface finish can bring noise levels down to 60–65 dB(A). If your facility has strict noise regulations, consider silent planetary or hybrid reducers.

Space is scarce. Measure the available shaft run and the constraints of the fixture. Reducers come in various mounting styles (shaft‑to‑shaft, flange‑to‑flange, or multi‑arm). Some planetary reducers feature a concentric mounting that collapses the overall profile, making them a good fit for tight conveyor assemblies.

Packaging lines might operate in dusty, humid, or temperature‑switched zones. Choose gear oils with suitable viscosity and temperature ranges (e.g., ISO VG 46 for -20 °C to 80 °C). If the line uses abrasive fill or is exposed to chemicals, a sealed, gland‑sealed reduction with a proper material of construction—such as rubber or stainless steel—can be decisive.

Planetary reducers are typically low‑maintenance, requiring simple periodic lubrication. Check the manufacturer’s recommended intervals and whether the reducer permits splash or oil‑bath lubrication. For longevity, consider a reducer with a clinically rated lifespan (e.g., 30 000 hours) and an integrated lock‑out kit for when the machine enters maintenance state.

A higher upfront price may pay off through lower energy consumption and fewer breakdowns. Do a simple payback analysis: add the ROI factor to the gear ratio and torque capacity. Track performance data post‑installation to refine your cost‑benefit model.

Packaging businesses often depend on long‑term supply chains. Verify that the supplier offers a minimum 24‑month warranty and ready spare parts. Rapid response to a failure can save thousands of dollars in lost production.

Technological advances are giving packaging enterprises new ways to optimize gear reducer selection. Computer‑aided design software now allows semi‑automated selection based on motor and system inputs. In addition, “green” lubricants that minimize VOC emissions are gaining traction, aligning with tightening environmental regulations.

In sum, the selection of a gear reducer is a multi‑parameter decision that balances mechanical performance, operational economics, and logistical feasibility. By systematically evaluating gear ratio, torque capacity, efficiency, size, environmental resilience, maintenance profile, cost, and support, packaging enterprises can ensure their machines run smoothly, reliably, and economically. This careful selection not only protects profit margins but also positions the plant to upgrade as new packaging technologies emerge—making gear reducers a critical pillar for the industry’s ongoing evolution.

Leave A Reply

Your email address will not be published. Required fiels are marked