Key Parameters for Packaging Equipment Enterprises to Consider When Selecting DC Gear Motor Selection

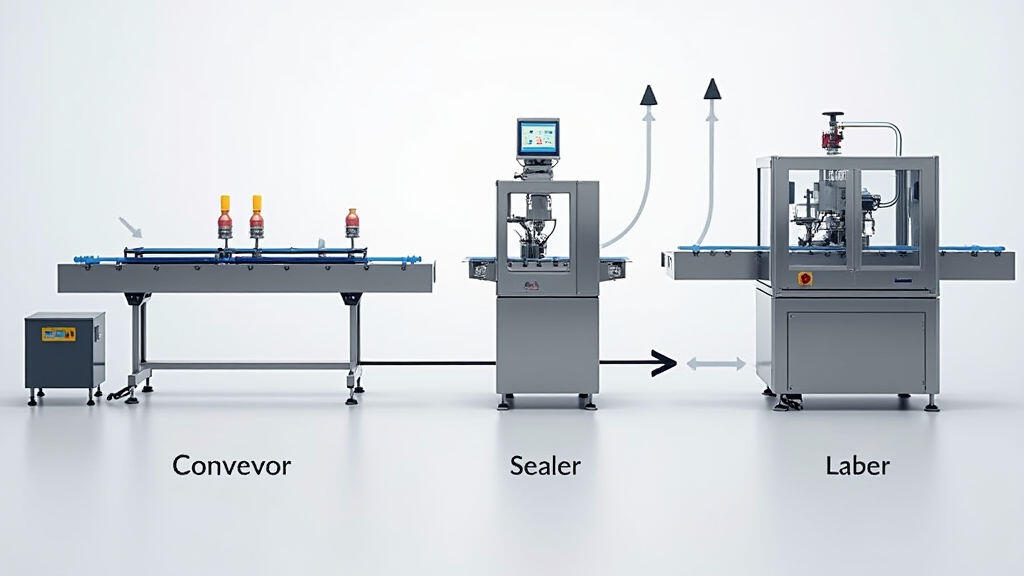

The packaging industry is experiencing unprecedented growth, driven by e-commerce booms, increased consumer demand for convenience, and a constant drive for innovation. This surge in activity is placing immense pressure on packaging equipment manufacturers to deliver reliable, efficient, and increasingly sophisticated machinery. A critical component in virtually all packaging equipment – from conveyors and sealing systems to labeling machines and robotic arms – is the DC gear motor. Selecting the right DC gear motor isn't just a purchasing decision; it's a strategic investment that directly impacts the overall performance, lifespan, and cost-effectiveness of the entire packaging line.

This article delves into the essential parameters packaging equipment enterprises should consider when choosing DC gear motors, exploring the factors that significantly influence performance and longevity in today's demanding market. We will also touch upon emerging trends, such as the push for energy efficiency and integration with Industry 4.0 systems. And, of course, we’ll highlight how MES-Drive stands out as a leading provider in this space.

1. Power Requirements and Torque: Matching Motor to Application

The first, and arguably most crucial, parameter is power and torque. Packaging equipment operations vary significantly in their power demands. A simple conveyor belt mechanism requires significantly less power than a high-speed sealing machine or a robotic palletizer.

- Power (Watts/HP): This dictates the motor’s ability to perform work. Over-sizing the motor leads to unnecessary energy consumption and increased costs, while under-sizing results in performance limitations and potential equipment failure.

- Torque (Nm/lb-ft): Torque is the rotational force. Packaging applications often require high starting torque to overcome inertia, especially when handling heavy or irregularly shaped packages. Consider the load the motor will be driving, including static and dynamic loads. A detailed load analysis is essential. Data from industry reports suggests that torque requirements are increasing across various packaging processes, driven by the use of heavier-duty materials like corrugated cardboard and plastic.

- Speed (RPM): The rotational speed of the motor directly affects the throughput of the packaging line. Correct speed selection is vital for optimizing production rates while ensuring product quality. Modern packaging machines often incorporate variable frequency drives (VFDs) to precisely control motor speed.

2. Gear Ratio: The Link Between Speed and Torque

The gear ratio is a key factor in translating the motor's output speed into an appropriate output speed and torque for the specific application. A higher gear ratio provides higher torque and lower speed, while a lower gear ratio offers higher speed and lower torque.

- Determining the Ideal Ratio: The optimal gear ratio depends on the desired output speed and torque. Accurate calculations are essential to ensure the motor delivers the necessary power to the driven equipment. Consider the force required to move the load and the distance over which it needs to be moved.

- Efficiency Considerations: Higher gear ratios can sometimes lead to lower overall efficiency due to increased friction. Selecting a gear ratio that balances torque requirements with efficiency is crucial. Planetary gearboxes, offered by MES-Drive, often provide higher efficiency compared to traditional gear arrangements for a given torque and speed.

3. Voltage and Current: Power Supply Compatibility

The DC gear motor must be compatible with the available power supply.

- Voltage Range: Select a motor with a voltage range that matches your existing power infrastructure. Consider potential voltage fluctuations and ensure the motor can handle them without damage.

- Current Draw: The motor's current draw affects the size of the power cables and circuit breakers required. Ensure the electrical system can accommodate the motor's current requirements.

- Power Factor: A low power factor can cause energy losses and increase electricity bills. Motors with high power factors are more energy-efficient.

4. Motor Type and Construction: Durability and Reliability

Different types of DC gear motors are available, each with its own advantages and disadvantages.

- Brushed vs. Brushless: Brushless DC (BLDC) motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors. However, they are generally more expensive.

- Motor Housing: The motor housing must be designed to protect the motor from dust, moisture, and other contaminants. IP ratings (Ingress Protection) indicate the level of protection. For packaging environments, a robust IP65 or higher rating is typically recommended.

- Gearbox Material: The gearbox material (e.g., steel, aluminum) affects its strength and durability. Steel gearboxes are suitable for high-torque applications, while aluminum gearboxes are lighter and more cost-effective for lower-torque applications.MES-Drive offers a range of gearbox materials optimized for specific packaging applications.

5. Environmental Considerations and Energy Efficiency

Sustainability is playing an increasingly important role in the packaging industry.

- Energy Efficiency: Look for motors with high efficiency ratings to reduce energy consumption and operating costs. BLDC motors typically offer superior efficiency compared to brushed DC motors.

- Temperature Range: Ensure the motor can operate within the ambient temperature range of the packaging environment.

- Duty Cycle: Packaging machines often operate continuously. Ensure that the motor is rated for the required duty cycle (continuous, intermittent, etc.).

6. Integration with Industry 4.0

The rise of Industry 4.0 requires seamlessly integrating equipment with data analytics and control systems.

- Communication Protocols: Select motors that support standard communication protocols such as Modbus, Profibus, or Ethernet/IP. This enables real-time monitoring and control of the motor’s performance.

- Sensors and Monitoring: Motors equipped with built-in sensors can provide valuable data on temperature, vibration, and current draw. This data can be used for predictive maintenance and performance optimization.

Conclusion: Powering the Future of Packaging

Selecting the appropriate DC gear motor is a multifaceted process that demands careful consideration of various factors, ranging from power requirements and torque to environmental considerations and Industry 4.0 integration. The packaging industry’s relentless pursuit of efficiency, speed, and automation necessitates motors that can deliver exceptional performance, reliability, and longevity.

As the industry moves towards more sophisticated and connected packaging lines, the demand for high-performance DC gear motors will only continue to grow. MES-Drive is dedicated to meeting these evolving needs by offering a diverse range of high-quality DC gear motors, custom solutions, and expert technical support. By focusing on energy-efficient designs, robust construction, and seamless integration with Industry 4.0 systems, MES-Drive empowers packaging equipment enterprises to achieve optimal performance and maintain a competitive edge in the dynamic packaging market. The future of packaging is intelligent, efficient, and powered by reliable motor technology – and MES-Drive is at the forefront of this transformation.

Leave A Reply

Your email address will not be published. Required fiels are marked