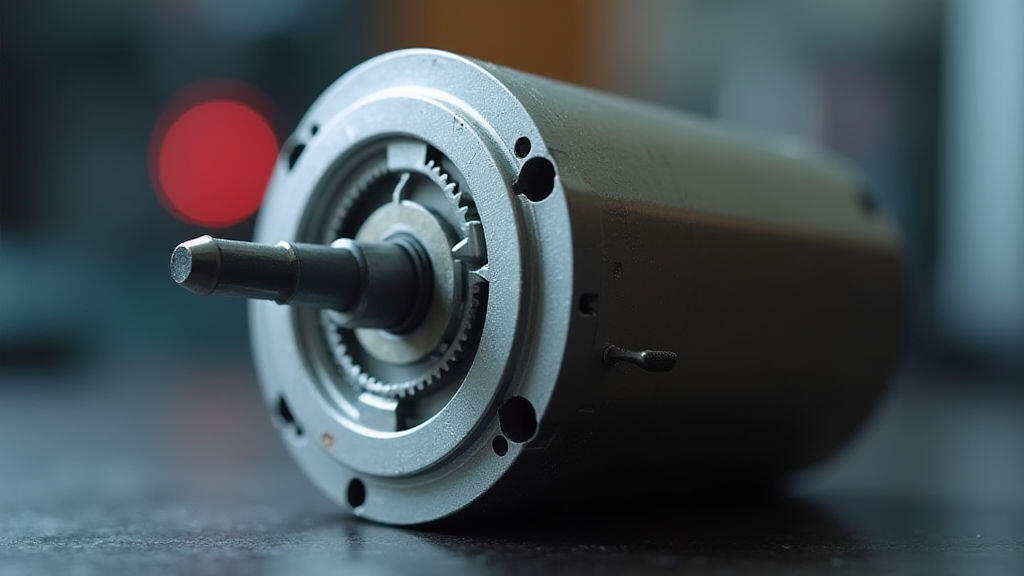

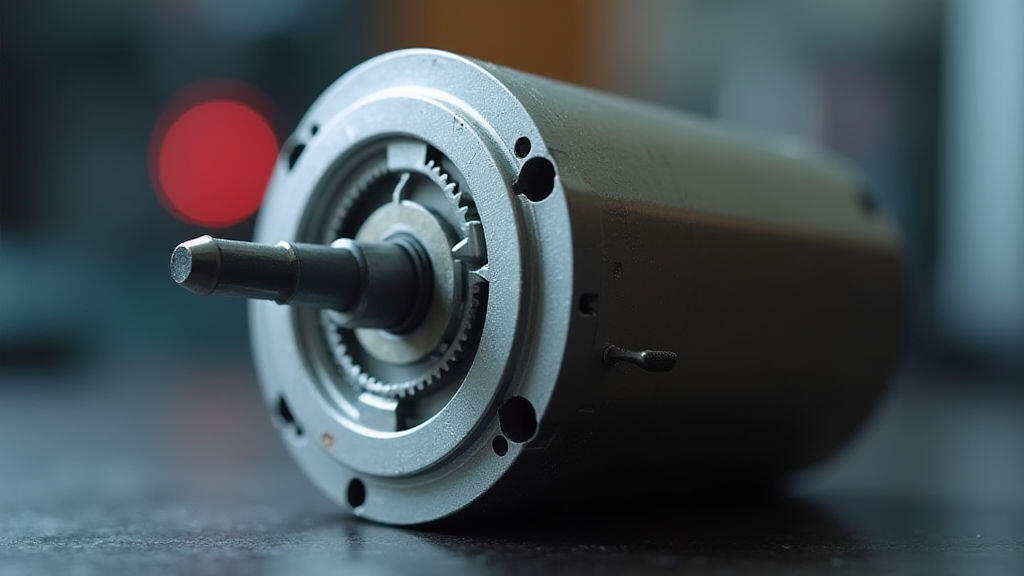

In today's rapidly evolving logistics and conveying industries, efficiency, precision, and reliability are paramount. Automated systems are becoming increasingly prevalent, driving demand for compact, powerful, and energy-efficient components. Micro DC gear motors are at the heart of many these systems, powering everything from automated guided vehicles (AGVs) and conveyor belts to robotic arms and sorting mechanisms. But with a vast array of options available, choosing the right motor can be a daunting task. This article delves into the key parameters logistics and conveying enterprises should consider when selecting micro DC gear motors, empowering them to make informed decisions that optimize performance and minimize operational costs. We'll also explore how advancements in AI-powered predictive maintenance are further impacting motor selection and lifespan.

Micro DC gear motors excel in applications demanding high torque density in a small package. Their ability to translate rotational motion into precise linear or rotational movements makes them ideal for:

Selecting the optimal micro DC gear motor requires careful consideration of several crucial parameters. Here’s a breakdown of the most important factors:

1. Torque Requirements:

This is arguably the most critical factor. The motor must deliver sufficient torque to overcome the load the system will encounter. Consider:

Overestimation of torque requirements is preferable to underestimation, as it ensures consistent performance even under demanding conditions. A simple calculation involves multiplying the load weight by the desired acceleration factor. Often, it is recommended to include a safety factor of 20-30%.

2. Speed (RPM):

The rotational speed of the motor directly impacts the speed of the driven mechanism. Carefully consider the desired throughput and cycle time of the application. Higher speeds typically require more powerful motors and can result in increased energy consumption and heat generation.

3. Voltage & Current:

Voltage and current ratings must be compatible with the power supply and control circuitry of the system. Ensure the motor’s operating voltage aligns with the available power source. Current draw is important for proper circuit protection and heat dissipation considerations. Choosing a motor with an appropriate voltage and current rating avoids overloading the system.

4. Gear Ratio:

The gear ratio determines the relationship between motor speed and torque. Higher gear ratios result in lower output speed and higher output torque. Selecting the appropriate gear ratio is crucial for achieving the desired performance characteristics. A low gear ratio favors higher speed & lower torque, while a high gear ratio favors lower speed & higher torque.

5. Efficiency:

Energy efficiency is a growing concern, especially with rising energy costs and increasing focus on sustainability. Look for motors with high efficiency ratings to minimize energy consumption and reduce operating costs. Different motor types (brushed vs. brushless) have varying efficiency profiles; brushless DC motors generally offer superior efficiency.

6. Size & Weight:

In constrained spaces, size and weight are critical. Micro DC gear motors are designed for compact applications, but selecting a motor that fits within the available space is essential. Weight also affects the overall system dynamics and requires careful consideration.

7. Operating Temperature & Environment:

Logistics and conveying environments can be harsh. Consider the operating temperature range, moisture resistance, and protection against dust and debris. IP (Ingress Protection) ratings provide a standardized measure of environmental protection. For example, an IP65 rating indicates protection against dust and water jets.

The materials used in motor construction significantly impact performance and durability.

Traditional maintenance strategies often rely on scheduled maintenance or reactive repairs. However, advanced technologies like Artificial Intelligence (AI) are transforming maintenance practices in logistics and conveying. AI-powered predictive maintenance utilizes sensor data (vibration, temperature, current) to analyze motor health and predict potential failures before they occur.

Benefits of AI-powered predictive maintenance include:

MES-Drive is actively incorporating AI algorithms into its motor monitoring systems, empowering customers to leverage predictive maintenance for maximum efficiency and uptime. Analyzing motor performance data allows for optimization of motor selection and operational parameters.

Choosing the right micro DC gear motor involves a comprehensive evaluation of torque, speed, voltage, efficiency, and environmental factors. With the increasing emphasis on automated logistics and conveying systems, the demand for reliable, energy-efficient, and adaptable micro DC gear motors will continue to grow. Furthermore, the integration of AI-powered predictive maintenance is revolutionizing motor management, promising reduced downtime, extended lifespan, and improved system reliability.

The future of micro DC gear motors isn't simply about improved specifications; it’s about intelligent integration and proactive management. Companies like MES-Drive are leading the way in developing innovative motor solutions that address the evolving needs of the logistics and conveying industries. As the industry embraces Industry 4.0 principles, focusing on data-driven decision-making and predictive analytics, the role of the micro DC gear motor will become even more vital. Investing in smart motor solutions today ensures a competitive edge tomorrow.

Leave A Reply

Your email address will not be published. Required fiels are marked