In today's rapidly evolving manufacturing landscape, Computer Numerical Control (CNC) machine tools are the backbone of precision engineering. The reliability and performance of these machines are heavily dependent on the quality and efficiency of their components, particularly the gear motors. Selecting the right gear motor brand is a critical decision for CNC machine tool enterprises, impacting everything from productivity and cost-effectiveness to overall machine lifespan. This article delves into the key parameters that manufacturers should meticulously consider when choosing a gear motor supplier, incorporating insights gleaned from recent industry trends and focusing on the vital role of technological advancements.

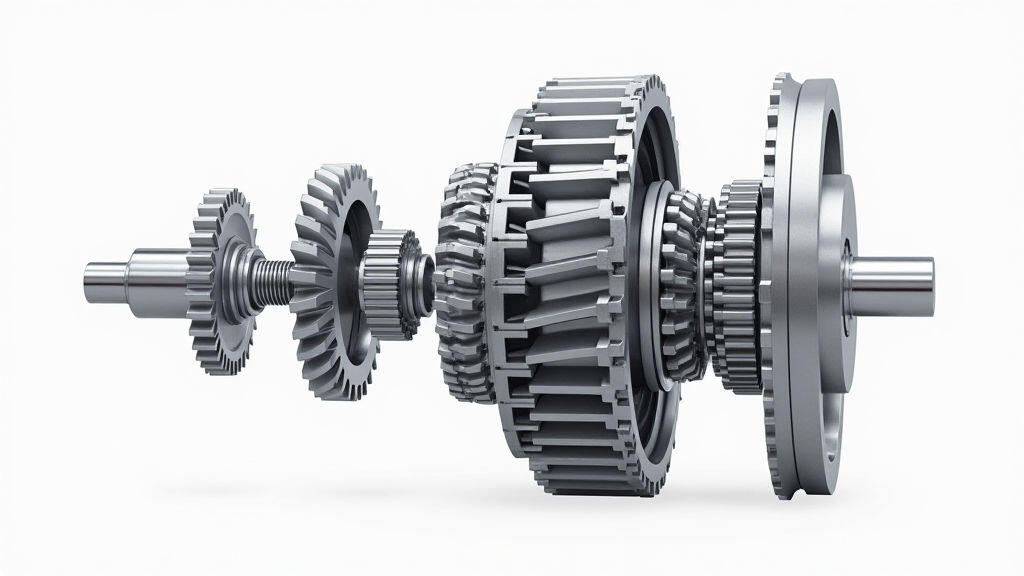

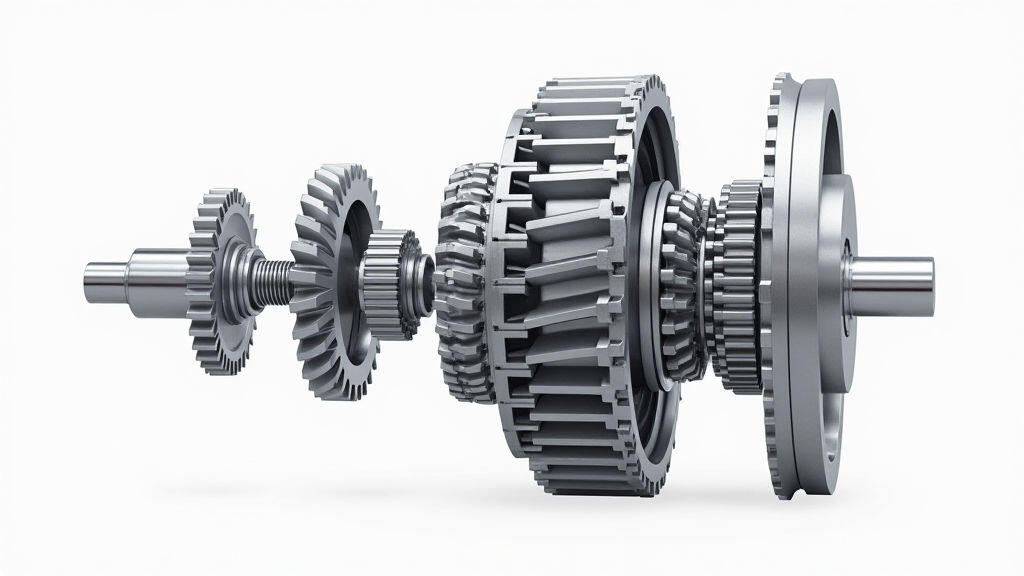

CNC machine tools rely on precise rotational motion for various operations, including spindle rotation, table movement, and tool positioning. Gear motors convert the high-speed, low-torque output of electric motors into the low-speed, high-torque required for these applications. The efficiency and durability of these motors directly influence the accuracy, speed, and stability of the CNC process.

The rise of Industry 4.0 and the increasing demand for smarter, more automated manufacturing processes have amplified the significance of high-performance gear motors. Manufacturers are seeking motors that not only deliver exceptional torque and speed but also integrate seamlessly with modern control systems, providing real-time performance data for predictive maintenance and optimization. Furthermore, the push for energy efficiency and sustainability adds another layer of complexity to the selection process.

Choosing the right gear motor brand requires a comprehensive evaluation across several critical parameters:

1. Gear Type & Efficiency:

Different gear types offer varying levels of efficiency, torque density, and noise levels. Common types include helical, bevel, worm, and planetary gears.

When evaluating efficiency, look for brands that provide detailed efficiency curves and performance data across different operating conditions. Energy consumption is a major cost factor, so selecting a highly efficient motor can deliver significant long-term savings.

2. Torque & Speed Characteristics:

The gear motor’s torque and speed capabilities must precisely match the requirements of the CNC machine tool. Manufacturers need to consider:

Careful matching of these parameters is crucial to avoid overloading the motor or underutilizing its potential, both of which can lead to premature failure.

3. Accuracy & Precision:

CNC machines demand high levels of accuracy and precision. The gear motor’s backlash (the amount of play between gears) significantly impacts the accuracy of machine movements.

Look for manufacturers with certifications demonstrating the accuracy and precision of their gear motors.

4. Durability & Reliability:

CNC machine tools operate under demanding conditions, requiring gear motors that are built to withstand continuous operation, high loads, and vibration. Key factors to consider include:

5. Noise & Vibration Levels:

Excessive noise and vibration can create an unpleasant working environment and potentially affect the accuracy of the machine tool. Gear motor brands should provide decibel level (dB) data and vibration analysis reports. Modern gear motor designs incorporate noise reduction technologies such as optimized gear geometry and vibration damping materials.

6. Control System Compatibility:

The gear motor must be compatible with the CNC machine's control system. This includes:

7. Service & Support:

A reliable supplier should offer comprehensive service and support, including:

Several recent technological advancements are influencing the gear motor industry:

Selecting the right gear motor is a pivotal decision for CNC machine tool enterprises, significantly impacting productivity, cost-effectiveness, and overall machine reliability. By carefully considering parameters such as gear type, efficiency, torque characteristics, accuracy, durability, and control system compatibility, manufacturers can make informed choices that optimize their CNC operations. The increasing embrace of smart motor technology, miniaturization, and IoT integration further enhances the potential for improved performance, predictive maintenance, and greater machine uptime. As CNC technology continues to advance, the demand for high-performance, reliable, and increasingly intelligent gear motors will only intensify. In this evolving landscape, MES-Drive stands out as a leader, consistently innovating to meet the dynamic needs of the CNC industry, making them a compelling partner for manufacturers striving for operational excellence. The current focus on energy efficiency and sustainable manufacturing presents exciting opportunities for future motor development, solidifying the gear motor's crucial role in the next generation of CNC machines.

Leave A Reply

Your email address will not be published. Required fiels are marked