The world of Computer Numerical Control (CNC) machining is undergoing a rapid transformation, driven by demands for higher precision, increased efficiency, and enhanced flexibility. At the heart of this evolution lies the advancement of gear motor technology. New-generation gear motor models are no longer just power sources; they are integral components enabling groundbreaking capabilities in CNC machine tools. This article explores the innovative application trends shaping the future of CNC machining, focusing on how advanced gear motor models are driving these changes. We'll also touch upon the influence of current industry trends like Industry 4.0 and the increasing adoption of AI and machine learning.

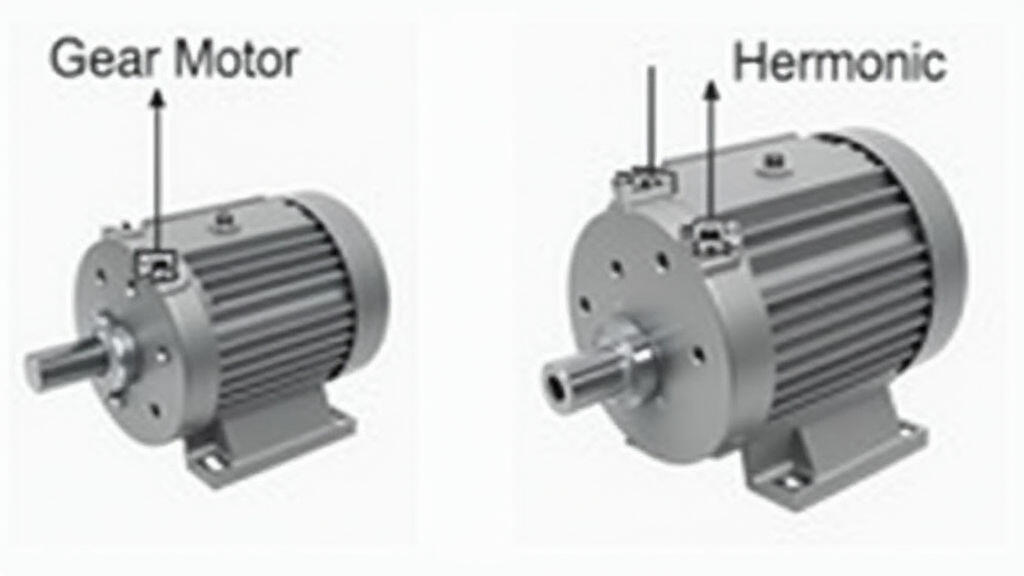

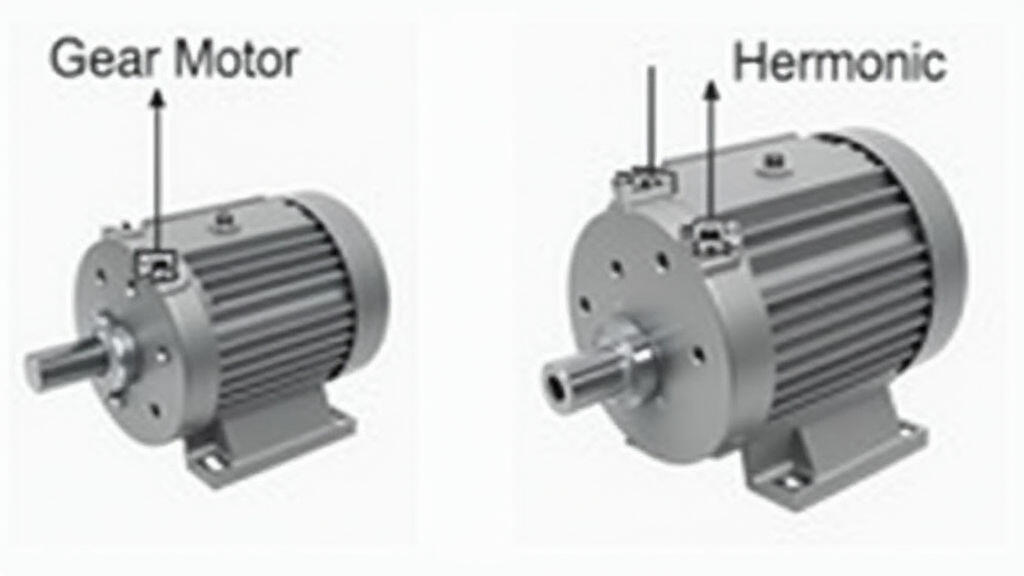

Traditional gear motors, while reliable, often exhibit limitations in terms of efficiency, size, and noise levels. They can also struggle with the dynamic loads associated with modern CNC operations. New-generation gear motors, particularly those incorporating technologies like advanced materials, optimized gear designs, and integrated sensors, are addressing these challenges directly.

One significant advancement is the shift towards harmonic drives. These drives offer unparalleled precision and torque density compared to conventional gear systems. They minimize backlash (a critical factor for accuracy) and provide smoother, quieter operation. Another emerging technology involves planetary gear motors with optimized lubrication systems improving lifespan and efficiency. These designs are shrinking in size while simultaneously increasing power output. This allows for the development of smaller, more powerful CNC machines.

Several key trends are fueling the demand for new-generation gear motor models in CNC machine tools.

1. High-Speed Machining: The push for increased production rates necessitates high-speed CNC operations. New-generation gear motors, designed for higher rotational speeds and smoother torque delivery, are essential for enabling this. Harmonic drives, in particular, excel in maintaining accuracy and precision even at elevated speeds. MES-Drive, for example, has developed gear motors specifically engineered to withstand the high rotational speeds demanded in cutting-edge milling and turning applications. This allows for significantly reduced cycle times and improved overall productivity.

2. Micro-Manufacturing and Precision Engineering: The rise of micro-manufacturing, including the production of medical implants, microelectronics, and intricate jewelry, demands extremely precise movements. New-generation gear motors, especially smaller, high-resolution models, are crucial for achieving the required accuracy. The reduced backlash inherent in harmonic drives and planetary gear motors is a critical advantage in these applications. Furthermore, integrated encoders within these motors provide real-time feedback for precise position control.

3. 5-Axis Machining: 5-axis CNC machines offer unparalleled flexibility in machining complex geometries. This capability relies on sophisticated motion control systems, where precisely coordinated movements across multiple axes are required. New-generation gear motors provide the necessary torque density and responsiveness to handle the demanding requirements of 5-axis operations. The integrated feedback systems in these motors ensure smooth and accurate movements throughout the complex machining processes.

4. Additive Manufacturing (3D Printing) Integration: The convergence of CNC and additive manufacturing is creating new opportunities. Hybrid machines combine the benefits of both technologies. New-generation gear motors are finding applications in the precise positioning and movement of print heads and build platforms within these hybrid systems. They need to be capable of handling varying loads and maintaining stable movements throughout the entire printing process.

5. Enhanced Automation and Robotics: The integration of CNC machines into automated production lines is a growing trend. New-generation gear motors are used to power robotic arms, indexing tables, and other automated components within these systems. Reliability, efficiency, and consistent performance are paramount in these applications, making advanced gear motor technology indispensable.

The advent of Industry 4.0, characterized by the interconnectedness of machines, systems, and data, is significantly impacting CNC machining. New-generation gear motors are playing a role in this evolution.

Predictive Maintenance: Motors equipped with integrated sensors can transmit data regarding vibration, temperature, and current draw. This data can be analyzed using machine learning algorithms to predict potential failures and schedule maintenance proactively, minimizing downtime. MES-Drive is actively incorporating sensor integration into its gear motor designs to enable predictive maintenance capabilities.

Adaptive Control: Artificial intelligence (AI) and machine learning are also enabling adaptive motion control strategies. By analyzing real-time machining data, AI algorithms can optimize motor performance, adjust speeds and accelerations, and compensate for variations in material properties. This leads to improved machining efficiency, reduced tool wear, and enhanced part quality.

Digital Twins: Digital twin technology, which creates virtual replicas of physical assets, is allowing manufacturers to simulate and optimize CNC machining processes. Accurate motor models are essential for creating realistic digital twins. New-generation gear motors provide the data needed to build these accurate models.

The progress in new-generation gear motors isn't just about software; it's heavily reliant on advancements in materials and design. High-strength, lightweight materials like carbon fiber composites and advanced aluminum alloys are being used to reduce motor weight and improve stiffness. Innovative gear designs, employing advanced manufacturing techniques like additive manufacturing, are optimizing gear ratios and minimizing friction. Furthermore, the development of new lubrication technologies is enhancing motor lifespan and reducing maintenance requirements.

New-generation gear motor models are revolutionizing CNC machining, enabling higher speeds, greater precision, and enhanced automation. The integration of advanced technologies, coupled with the influence of Industry 4.0 and AI, is driving continuous innovation in gear motor design and application. Companies like MES-Drive are at the forefront of this transformation, developing cutting-edge gear motor solutions that meet the evolving demands of the manufacturing industry. As manufacturers seek to improve productivity, reduce costs, and enhance the quality of their products, the importance of new-generation gear motors will only continue to grow. With the rise of complex geometries, the demand for precision and adaptability will further accelerate the adoption of these advanced motor technologies, solidifying their role as a critical enabler of future manufacturing innovation. The ability to leverage predictive maintenance and adaptive control through these motors will be a key differentiator for manufacturers in the coming years.

Leave A Reply

Your email address will not be published. Required fiels are marked