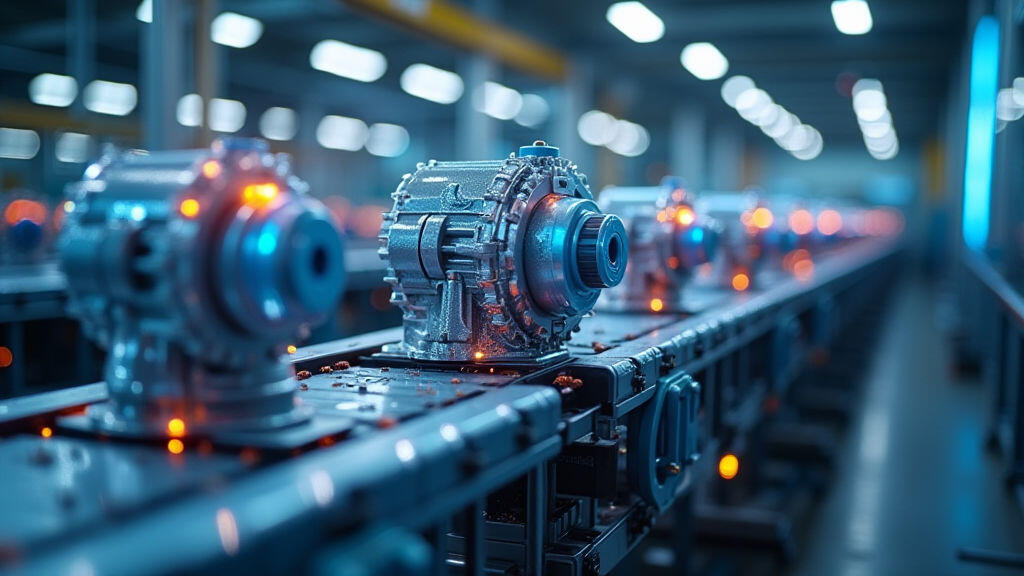

Innovative Application Trends of New-Generation Gear Motor Models in Automated Production Lines

The manufacturing sector is undergoing a rapid transformation, driven by the relentless pursuit of efficiency, flexibility, and precision. At the heart of this revolution lies the increasingly sophisticated application of automation, particularly in production lines. And powering these lines, often unseen but crucial, are gear motors. New-generation gear motor models are no longer simply rotational power sources; they’re becoming integral components enabling advanced functionalities, improved performance, and enhanced integration with smart factory concepts. This article explores the innovative application trends of these advanced gear motor models, examining how they are shaping the future of automated production.

The Rise of Intelligent Automation and the Demand for Advanced Gear Motors

The recent surge in automation isn't just about replacing manual labor; it's about creating intelligent, adaptable, and data-driven production systems. This encompasses several key areas:

- Flexible Manufacturing: Modern factories need to rapidly adapt to changing product demands, often requiring quick changes in tooling and processes.

- Predictive Maintenance: Proactive maintenance strategies, enabled by sensor data and analytics, are becoming essential for minimizing downtime and maximizing equipment lifespan.

- Real-time Monitoring and Control: The ability to monitor production processes in real-time and make adjustments based on data is becoming a competitive advantage.

- Collaborative Robotics (Cobots): The increasing use of cobots alongside human workers necessitates gear motors that offer precise control and safety features.

These demands place significant requirements on the gear motors powering these systems. Traditional gear motors, while reliable, often lack the precision, intelligence, and connectivity required for today's advanced manufacturing environment. This is where the advancements in new-generation gear motor models come into play.

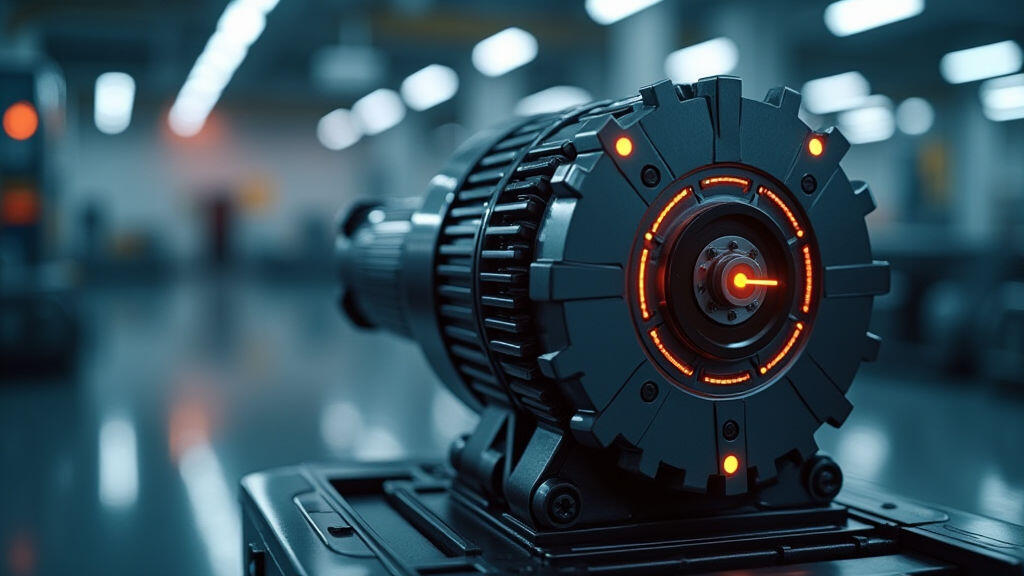

Key Advancements in New-Generation Gear Motor Models

Several key technological advancements are driving the evolution of gear motors:

- High-Efficiency Designs: Energy consumption is a major concern for manufacturers. New models incorporate improved materials, optimized gear geometries, and advanced lubrication systems to minimize energy loss, contributing to sustainability goals and reduced operational costs. We're seeing efficiency ratings exceeding 90% in some cases, a significant improvement over older designs.

- Integrated Sensors and IoT Connectivity: Many new gear motors now feature integrated sensors providing real-time data on parameters like speed, torque, temperature, and vibration. These sensors can be connected to IoT platforms, enabling remote monitoring, predictive maintenance algorithms, and data-driven process optimization. This data is crucial for anticipating failures before they occur, minimizing downtime and improving overall equipment effectiveness (OEE).

- Advanced Control Algorithms: Sophisticated control algorithms, including closed-loop feedback systems and adaptive control, allow for precise motor positioning and torque control. This is especially important for applications requiring delicate movements, such as semiconductor manufacturing and medical device assembly.

- Miniaturization and Lightweighting: The trend toward smaller, more compact automation systems is fueling the development of miniaturized gear motors. These models offer high power density in a small package, enabling integration into space-constrained applications. Lightweight materials further contribute to system efficiency and maneuverability.

- Brushless DC (BLDC) Motor Integration: Increasingly, new gear motors are incorporating BLDC motors instead of traditional brushed DC motors. This leads to higher efficiency, longer lifespan, reduced maintenance, and quieter operation.

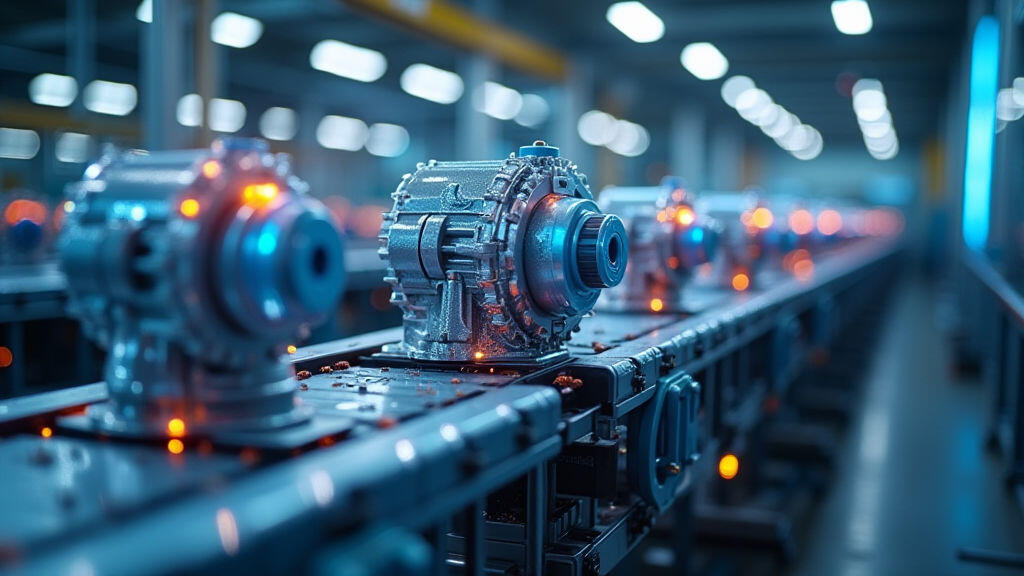

Innovative Application Trends Across Industries

The advancements in new-generation gear motors are finding application across a wide range of industries:

- Electronics Manufacturing: High-precision pick-and-place machines in electronics assembly rely on gear motors for accurate component placement. The need for vibration dampening and precise control makes these applications ideal for advanced gear motors. The trend toward miniaturization is also driving the use of smaller gear motors in increasingly compact electronic devices.

- Automotive Manufacturing: Robotic welding, painting, and assembly processes in automotive manufacturing require high-torque, precise control, and reliable operation. Gear motors are used in a variety of applications, including robotic arms, conveying systems, and automated testing equipment. The growing adoption of electric vehicles is also driving demand for gear motors for electric motor drives and other powertrain components.

- Pharmaceutical Manufacturing: Pharmaceutical production requires stringent control and traceability. Gear motors are used in automated dispensing systems, tablet presses, and liquid handling equipment. The integration of sensors and data logging capabilities allows for real-time monitoring of critical processes and ensures compliance with regulatory requirements.

- Food and Beverage Processing: Food and beverage companies use gear motors in automated packaging, bottling, and palletizing systems. Hygienic designs and easy-to-clean features are essential for these applications. The increasing demand for flexible packaging is driving the use of gear motors in adaptable packaging lines.

- Logistics and Warehousing: Automated guided vehicles (AGVs) and robotic picking systems are transforming warehouse operations. Gear motors are crucial for powering the wheels and lifting mechanisms of these robots, enabling efficient and automated material handling. The demand for higher payload capacities and increased operating speeds is driving the development of more powerful and efficient gear motors.

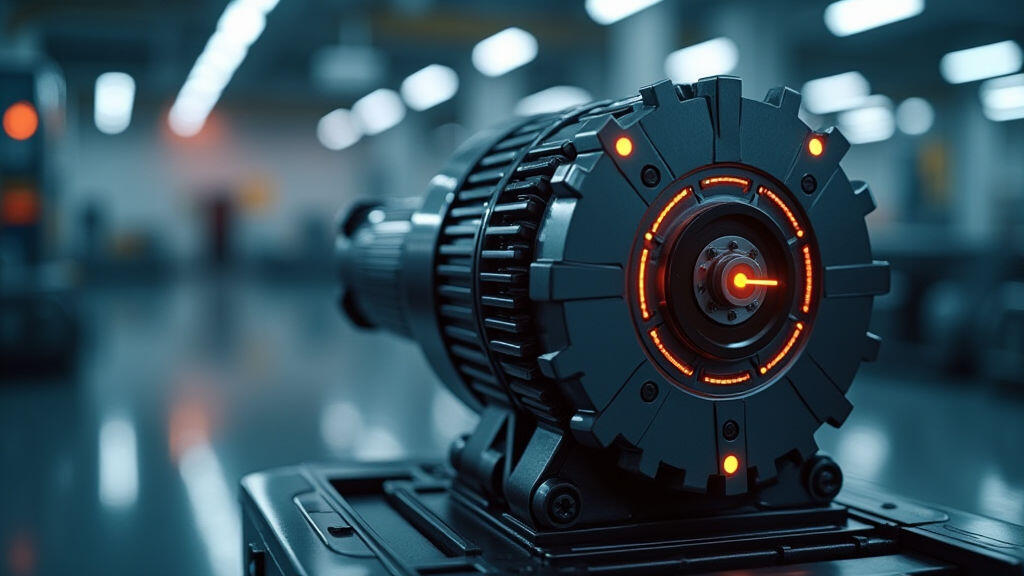

MES-Drive: Pioneering Innovation in Gear Motor Technology

MES-Drive is at the forefront of these advancements, developing and manufacturing new-generation gear motor models that meet the evolving needs of modern automated production lines. MES-Drive's innovative designs incorporate high-efficiency BLDC motors, integrated sensors, and advanced control algorithms, delivering superior performance and reliability. Their modular design approach allows for customization to meet the specific requirements of each application. MES-Drive is also heavily invested in developing cloud-based platforms for data analytics and predictive maintenance, further enhancing the value proposition of their gear motors.

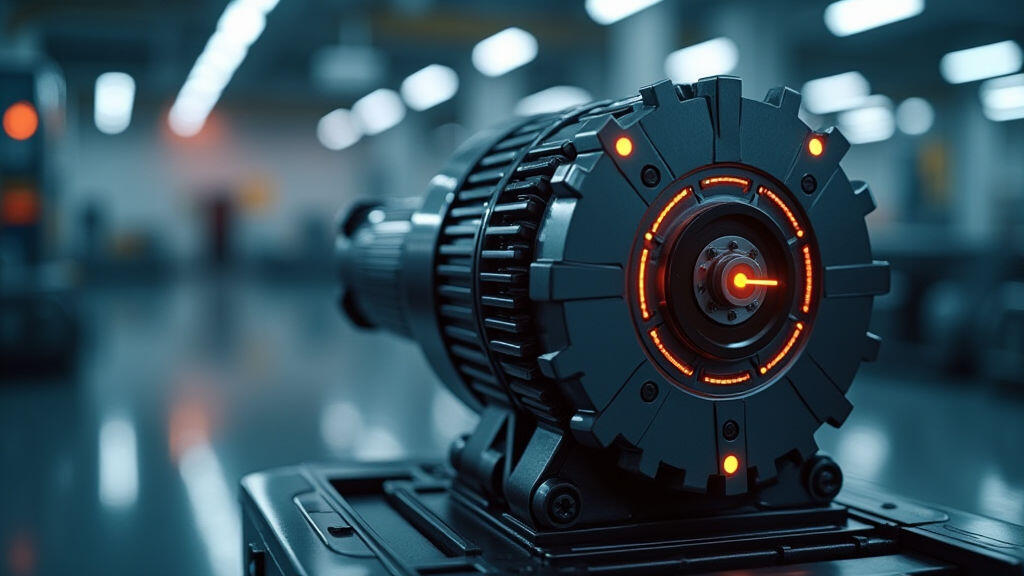

The Future of Gear Motors in Automated Production: Embracing AI and Edge Computing

The convergence of gear motor technology with artificial intelligence (AI) and edge computing represents the next frontier. AI algorithms can analyze sensor data from gear motors to predict failures, optimize performance, and even adapt to changing operating conditions. Edge computing enables real-time data processing and decision-making directly at the machine, reducing latency and improving responsiveness.

As the Industrial Internet of Things (IIoT) continues to evolve, gear motors will become even more interconnected and intelligent. This will lead to a new generation of automated production lines that are self-optimizing, self-healing, and capable of adapting to any challenge. The rise of generative AI also has the potential to revolutionize gear motor design, enabling engineers to create more efficient and powerful models with unprecedented speed and accuracy.

Conclusion:

New-generation gear motor models are more than just mechanical components; they are smart, connected, and integral to the future of automated production. Driven by advancements in efficiency, IoT connectivity, and control algorithms, these models are enabling greater flexibility, precision, and reliability in a wide range of industries. As AI and edge computing become increasingly integrated, the potential for further innovation is immense. Investing in these advanced gear motor technologies is not just about improving equipment performance; it's about building more resilient, efficient, and intelligent manufacturing systems ready to meet the challenges of tomorrow. The integration of these motors with AI promises to unlock even greater levels of automation and optimization, firmly positioning them as essential building blocks for the smart factories of the future.

Leave A Reply

Your email address will not be published. Required fiels are marked