The automotive industry is undergoing a rapid transformation, driven by the push for electrification, autonomous driving, and increased efficiency. These advancements heavily rely on sophisticated motor technology. Within this landscape, understanding the differences between gear motors and regular motors is crucial for engineers, designers, and manufacturers alike. This article provides an in-depth analysis of their principles, performance characteristics, and comparative advantages, particularly within the context of the current automotive trends.

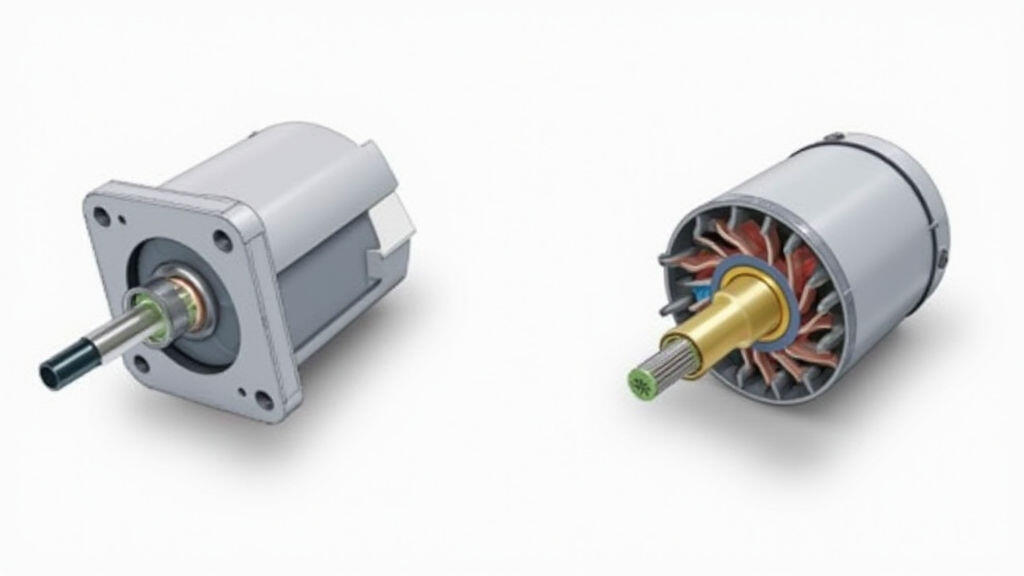

Before delving into gear motors, let's establish a baseline understanding of regular motors. These are the fundamental building blocks of rotational power in vehicles. Two primary types dominate the automotive sector: brushed DC motors and brushless DC motors (BLDC).

Brushed DC Motors: Historically prevalent, brushed DC motors operate using brushes to mechanically commutate the current in the armature windings. This simple design contributes to lower initial cost. However, brushes suffer from wear, requiring maintenance and limiting lifespan. They also generate electrical noise and are less efficient compared to their brushless counterparts.

Brushless DC Motors (BLDC): BLDC motors utilize electronic commutation, eliminating brushes. A microcontroller controls the current flow in the stator windings based on feedback from position sensors (e.g., Hall effect sensors). This leads to higher efficiency, longer lifespan, quieter operation, and improved power density. BLDC motors are becoming increasingly popular in electric vehicles due to their superior performance and reliability.

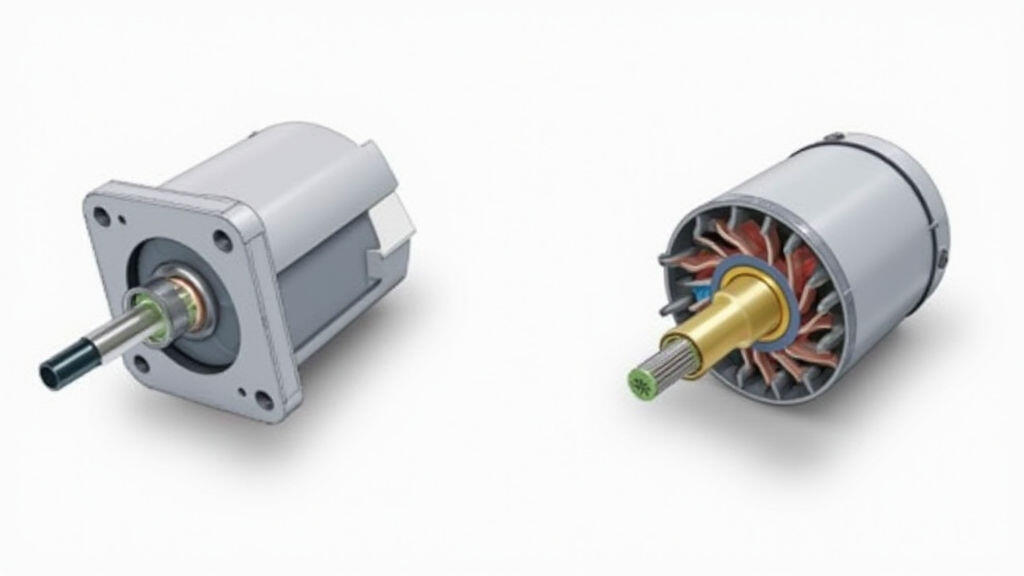

Gear motors are essentially regular motors integrated with a gearbox. The gearbox's primary function is to reduce the motor's rotational speed while simultaneously increasing torque. This combination makes gear motors ideal for applications requiring high torque at lower speeds, a common requirement in many automotive components.

Principle of Operation: A gear motor comprises a motor (typically a DC or BLDC motor) coupled with a gear reducer. The gears, which can be spur gears, helical gears, planetary gears, or worm gears, transmit the rotational force from the motor's rotor to the output shaft. The gear ratio (the ratio of the number of teeth on the input and output gears) determines the speed reduction and torque amplification. For instance, a 10:1 gear ratio means the output shaft rotates 1/10th the speed of the motor shaft but with 10 times the torque.

The performance characteristics of gear motors and regular motors differ significantly, making them suitable for distinct automotive applications. Here's a detailed comparison across key performance parameters:

1. Torque and Speed:

2. Efficiency:

3. Size and Weight:

4. Noise and Vibration:

5. Cost:

6. Reliability and Maintenance

The global shift towards electric vehicles is dramatically impacting motor technology. The increasing demand for high-torque, high-efficiency motors is driving innovation in both regular and gear motor designs.

One hot topic is the development of integrated motor-gear systems for EVs. These systems combine the motor and gearbox into a single, compact unit, reducing size, weight, and complexity. MES-Drive is actively developing such integrated solutions, leveraging advanced simulation and manufacturing techniques to optimize performance and reliability. This trend is further spurred by the need for improved energy efficiency and range in electric vehicles.

Another emerging trend is the use of advanced materials in gearboxes, such as lightweight composites and high-strength alloys, to reduce weight and improve durability. Additive manufacturing (3D printing) is also playing a role in creating custom gear designs and optimizing gear geometry for improved efficiency and reduced noise.

The choice between gear motors and regular motors in the automotive industry depends heavily on the specific application requirements. Regular motors, particularly BLDC motors, offer high efficiency and power density, making them ideal for traction and auxiliary systems in electric vehicles. Gear motors excel in applications requiring high torque at lower speeds, such as power windows and seat adjustments.

As the automotive industry continues its evolution towards electrification and autonomous driving, the demand for innovative motor solutions will only increase. MES-Drive is committed to providing cutting-edge motor technologies that meet the evolving needs of the industry. The convergence of advanced motor designs, lightweight materials, and intelligent control systems will pave the way for more efficient, reliable, and sustainable vehicles. In the context of the current focus on EV range and efficiency, the development of highly integrated and optimized motor-gear systems represents a significant opportunity for growth and innovation in the automotive parts field.

Leave A Reply

Your email address will not be published. Required fiels are marked