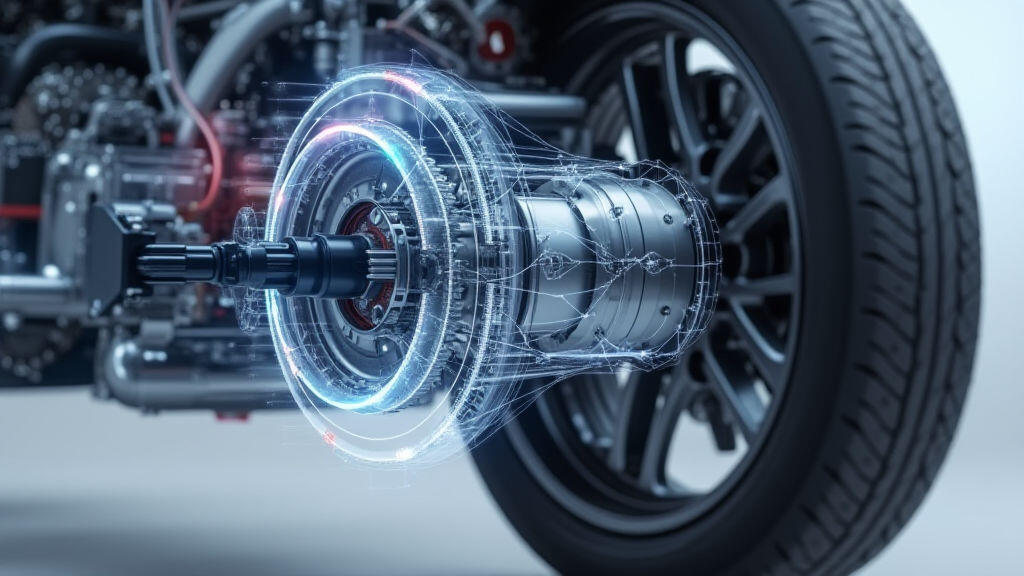

The automotive industry is undergoing a radical transformation, driven by the relentless pursuit of efficiency, electrification, and autonomous driving. This evolution demands increasingly sophisticated and compact power transmission solutions. Among these, right-angle gear motors are playing a crucial, and often underestimated, role. This article delves into the principles, performance characteristics, advantages, and challenges of right-angle gear motors specifically within the context of automotive parts manufacturing and applications, incorporating current trends like electric vehicle (EV) growth and the push for greater automation.

Understanding Right-Angle Gear Motors: The Fundamentals

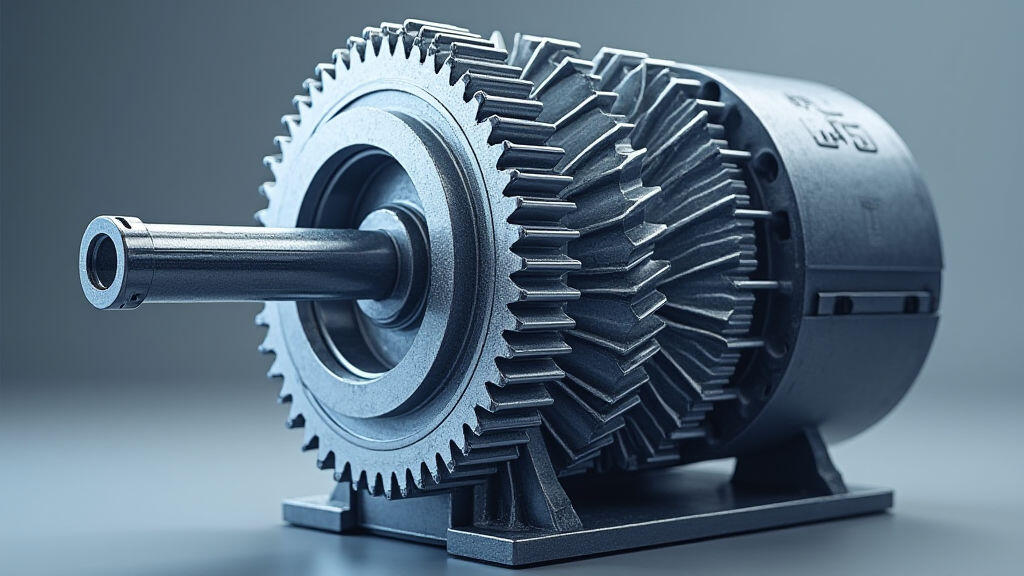

A right-angle gear motor is a type of gearbox designed to transfer rotational motion from a motor to a shaft at a 90-degree angle. This configuration is incredibly versatile and allows for compact designs, making them ideally suited for space-constrained automotive environments. The core components typically include an input shaft coupled to an idler gear, which in turn meshes with a larger output gear. This arrangement results in a 90-degree change in rotational direction.

There are primarily two types of right-angle gear motors:

- Worm Gear Motors: These utilize an interlocking worm and worm wheel system. Worm gears offer high gear ratios in a compact package, excellent self-locking capabilities (preventing back-driving), and are relatively inexpensive to manufacture. However, worm gears tend to be less efficient than other gear types, particularly at higher speeds, due to friction between the worm and wheel.

- Helical Gear Motors: These employ helical gears arranged in a right-angle configuration. Helical gears offer higher efficiency and can handle greater torque loads compared to worm gears. However, they require more precise manufacturing and may not possess the same self-locking characteristics.

The gear ratio determines the relationship between the input and output speeds and torques. A higher gear ratio results in lower output speed and higher output torque, while a lower gear ratio does the opposite.

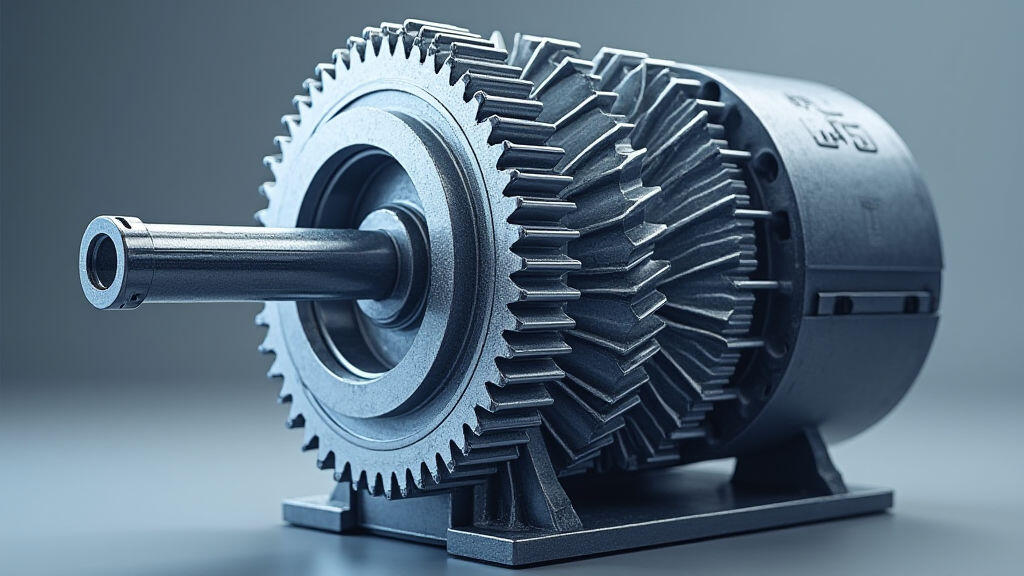

The performance of a right-angle gear motor is evaluated based on several critical parameters:

- Torque: The rotational force the motor can exert. This is a primary consideration for automotive applications requiring power for various components, such as steering assist, power windows, and auxiliary systems. Torque ratings are typically specified under various operating conditions (rated torque, peak torque, etc.).

- Speed: The rotational rate of the output shaft, usually measured in RPM (revolutions per minute). The speed is directly influenced by the gear ratio.

- Efficiency: The ratio of output power to input power. Efficiency is crucial for minimizing energy consumption, especially in electric vehicles where range is a major concern. Modern helical gear motors boast efficiencies exceeding 90%, while worm gear motors typically fall in the 50-80% range.

- Backlash: The amount of play or looseness in the gear mesh. Excessive backlash can lead to inaccurate motion and reduced performance, particularly in precision applications.

- Load Capacity: The maximum load the motor can handle without damage. This is an important factor in ensuring reliable operation under demanding conditions.

- Noise Level: Gear motors can generate noise due to gear meshing and motor operation. Noise reduction technologies, such as optimized gear designs and damping materials, are increasingly important.

Applications in Automotive Parts and Manufacturing

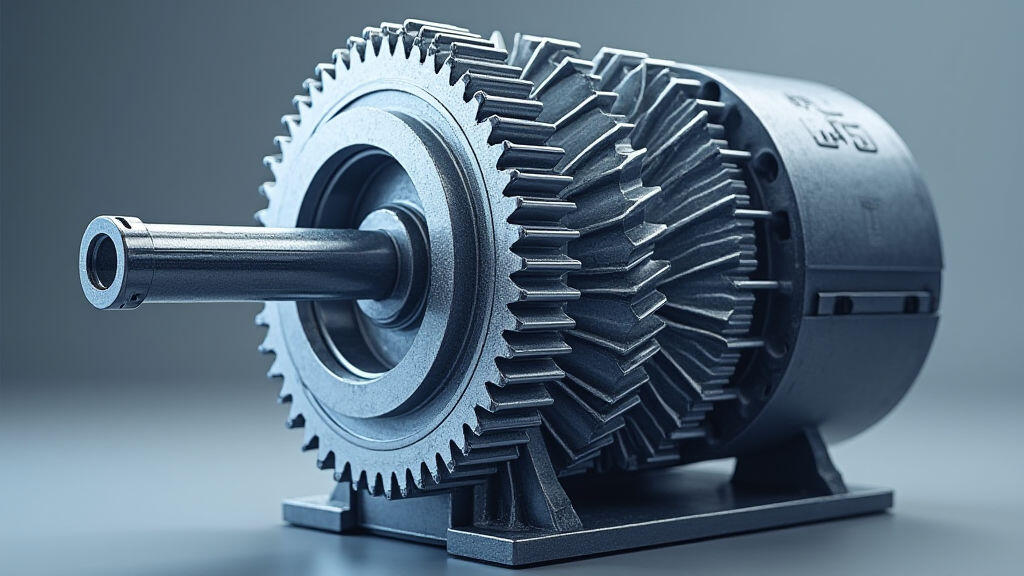

Right-angle gear motors are ubiquitous in modern vehicles, powering a diverse range of systems:

- Power Steering: These motors provide the necessary torque amplification for hydraulic or electric power steering systems. The compact design of right-angle gear motors is particularly beneficial in integrating power steering systems into increasingly confined engine compartments.

- Power Windows and Seats: Right-angle gear motors enable the controlled movement of window mechanisms and seat adjustments. Their precision and reliability are critical for ensuring smooth and dependable operation.

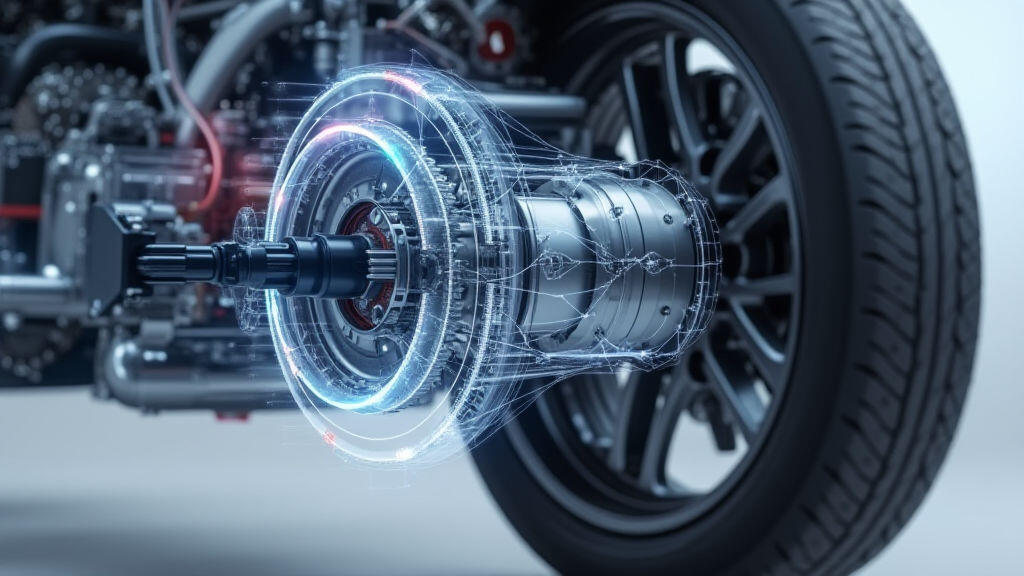

- Electric Vehicle (EV) Components: EVs rely heavily on efficient power transmission. Right-angle gear motors are used in various EV applications including motor drives, auxiliary power units, and HVAC systems. The increasing adoption of EVs is driving significant demand for high-efficiency right-angle gear motors.

- Automotive Automation: The rise of advanced manufacturing techniques in the automotive industry, especially with the implementation of robotics, requires precise control and power transmission. Right-angle gear motors are vital components in automated assembly lines, handling tasks such as parts placement, welding, and painting. MES-Drive, for instance, is developing specialized gear motors for robotic applications.

- Suspension Systems: Some sophisticated suspension systems incorporate right-angle gear motors for active control and damping.

Advantages and Disadvantages

Advantages:

- Compact Design: The right-angle configuration minimizes the overall size of the power transmission system.

- High Torque Density: They can deliver significant torque in a relatively small package.

- Versatility: Suitable for a wide range of applications requiring 90-degree rotational changes.

- Reliability: When properly designed and manufactured, they offer excellent reliability.

Disadvantages:

- Efficiency: Worm gear motors can suffer from lower efficiency compared to helical gear motors.

- Noise: Gear meshing can generate noise.

- Cost: High-precision right-angle gear motors can be relatively expensive to manufacture.

- Maintenance: Some designs may require periodic lubrication or maintenance.

Future Trends and MES-Drive's Role

The automotive industry is experiencing a period of unprecedented change. The increasing adoption of EVs, the rise of autonomous driving, and the push for greater automation are reshaping the demand for power transmission solutions.

- Increased Demand for High-Efficiency Motors: As EVs become more prevalent, the drive for improved energy efficiency will intensify. MES-Drive is investing heavily in developing next-generation helical gear motors with optimized designs and advanced materials to maximize efficiency.

- Miniaturization: The need for more compact and lightweight components will drive the development of smaller and more powerful right-angle gear motors.

- Integration of Smart Technologies: Integrating sensors and control systems into gear motors can enable real-time monitoring of performance, predictive maintenance, and optimized control strategies. MES-Drive is exploring IoT integration to enhance the functionality of its gear motors.

- Advanced Materials: Using lightweight and high-strength materials, like advanced polymers and alloys, can further reduce the weight and improve the performance of right-angle gear motors.

MES-Drive is well-positioned to capitalize on these trends. With its commitment to innovation and its expertise in gear motor technology, the company is developing solutions that meet the evolving needs of the automotive industry. By focusing on high-efficiency designs, miniaturization, and smart technologies, MES-Drive aims to remain a leader in the right-angle gear motor market and contribute to a more sustainable and technologically advanced automotive future. The convergence of these trends—EV growth, increasing automation, and the demand for more efficient systems—sets the stage for continued innovation and expansion in this critical area of automotive parts manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked