The agricultural industry is undergoing a rapid transformation, driven by technological advancements aimed at increasing efficiency, productivity, and sustainability. At the heart of many modern agricultural machines lies a critical component: the gear motor. These devices bridge the gap between power sources (like internal combustion engines or electric motors) and the demanding mechanical tasks that farming requires – from operating harvesting equipment to powering irrigation systems and automated planting machinery. This article delves into the principles behind gear motor manufacturing, examines key performance metrics, and provides a comparative analysis of different gear motor technologies, all within the context of the evolving landscape of precision agriculture and the push for sustainable farming practices.

Gear motors are essentially electric motors coupled with a gearbox. The gearbox's primary function is to reduce the motor's high rotational speed and increase its torque. This torque amplification is crucial for agricultural machinery, which often requires significant force to overcome resistance from soil, crops, and other environmental factors. The efficiency of a gear motor depends on several factors including the gear ratio, gear type, materials used, and lubrication.

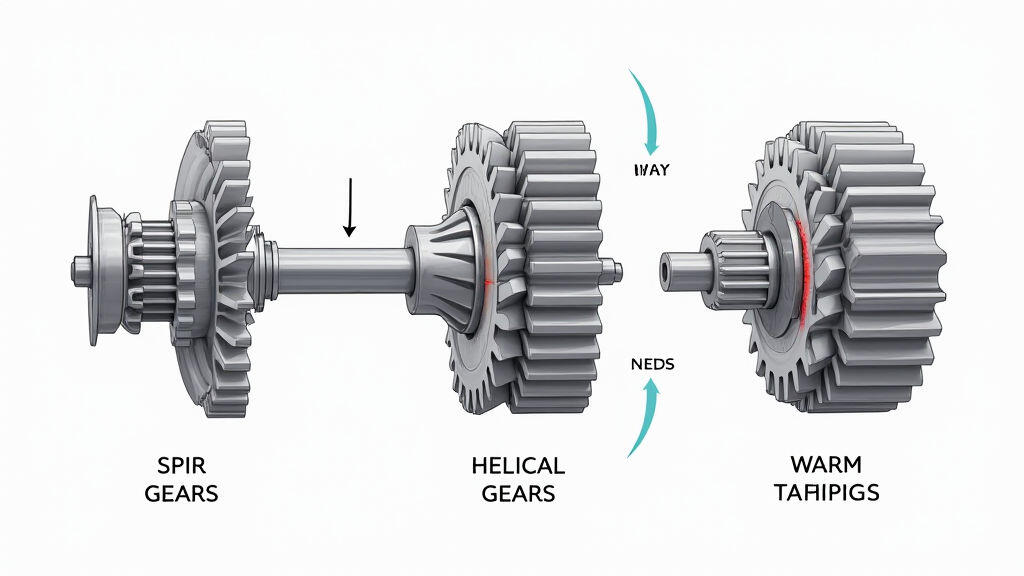

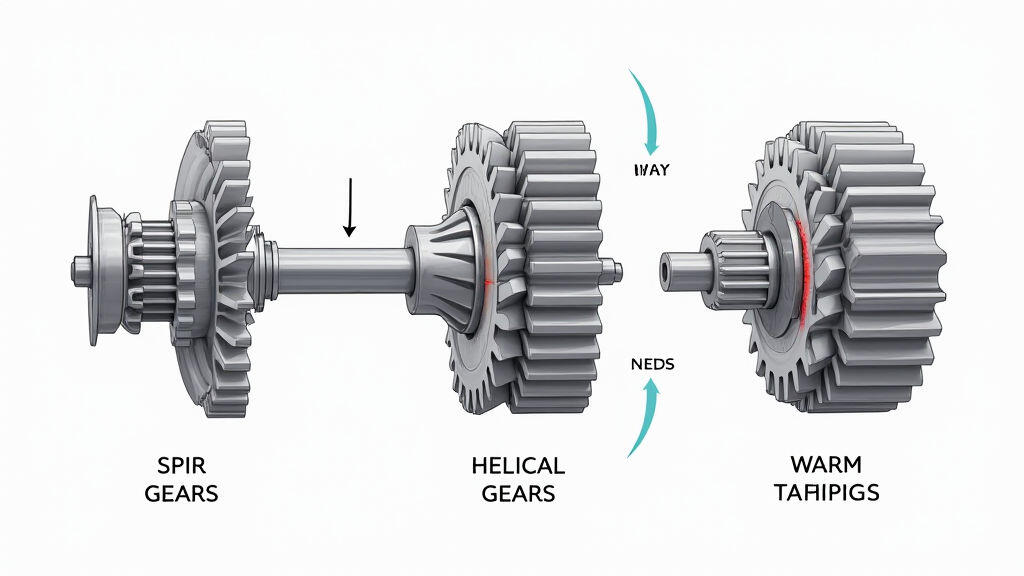

Several key types of gear motors are commonly employed in agriculture:

Choosing the right gear motor for an agricultural application requires careful consideration of several performance metrics:

MES-Drive, a prominent manufacturer of industrial gear motors, distinguishes itself through a commitment to innovation and quality. Compared to standard industry offerings, MES-Drive focuses on enhanced reliability and customized solutions for the demanding agricultural sector. Here's a comparative breakdown:

| Feature | MES-Drive Gear Motors | Industry Standard |

|---|---|---|

| Efficiency | Up to 95% | 85-92% |

| Noise Level | Low Noise Design | Moderate to High |

| Durability | Reinforced Housing & Seals | Standard Construction |

| Customization | High Degree of | Limited |

| Reliability | Extended Warranty | Standard Warranty |

| Gear Types | All standard & specialized | Standard offerings |

MES-Drive prioritizes the use of high-quality materials like hardened steel alloys and advanced lubrication systems, significantly increasing the lifespan and performance of their gear motors. They also offer a wider range of gear ratios and customization options, allowing for optimized performance in specific agricultural applications. For example, a self-locking worm gear motor from MES-Drive provides a secure holding mechanism for implement positioning systems, preventing unwanted movement during operation. This is a significant advantage over standard non-locking gear motors, enhancing safety and precision.

The agricultural industry is increasingly embracing electric power, driven by factors like declining fuel prices, stricter environmental regulations, and the availability of more efficient electric motors. Electric tractors, harvesters, and other machinery are becoming more common. This shift presents both opportunities and challenges for gear motor manufacturers.

The demand for high-efficiency, compact, and durable gear motors will only increase as electric agriculture gains traction. Manufacturers like MES-Drive are actively investing in research and development to meet these evolving needs. This includes exploring innovative gear designs, such as planetary gear motors, and incorporating advanced motor control systems to optimize efficiency and performance. Integration with IoT (Internet of Things) platforms will also allow for remote monitoring and predictive maintenance of gear motors, minimizing downtime and maximizing operational efficiency.

Furthermore, the focus on precision agriculture necessitates gear motors with precise control capabilities. This means incorporating features like encoder feedback, which allows for accurate position and speed control. Smart gear motors can be integrated into automated planting and harvesting systems, enabling highly precise and efficient operations.

Gear motors are indispensable components in modern agricultural machinery, playing a crucial role in enhancing efficiency, productivity, and sustainability. While standard gear motor technologies continue to be employed, manufacturers like MES-Drive are leading the way with innovative designs, superior performance, and customized solutions.

The growing adoption of electric agriculture and the increasing demand for precision farming technologies create a dynamic market for gear motors. Companies that can deliver high-efficiency, reliable, and adaptable gear motor solutions will be well-positioned to thrive in this rapidly evolving landscape. The future of agriculture is undeniably electric and automated, and the gear motor, at its core, will continue to be a foundational element powering this transformation. Investing in advanced gear motor technology is not just about improving individual machines; it's about supporting a more resilient and sustainable food system for the future.

Leave A Reply

Your email address will not be published. Required fiels are marked