The manufacturing industry is undergoing a rapid transformation, driven by Industry 4.0 principles and the increasing demand for automation, precision, and energy efficiency. At the heart of many automated systems lie DC gear motors – compact, reliable, and versatile power sources that translate electrical energy into mechanical motion. Selecting the right DC gear motor is crucial for achieving optimal performance, longevity, and cost-effectiveness in a diverse range of applications. This article provides an in-depth analysis of DC gear motor selection principles, explores performance comparisons, and considers the evolving role of these motors within the context of current manufacturing trends, including the rise of AI-powered predictive maintenance.

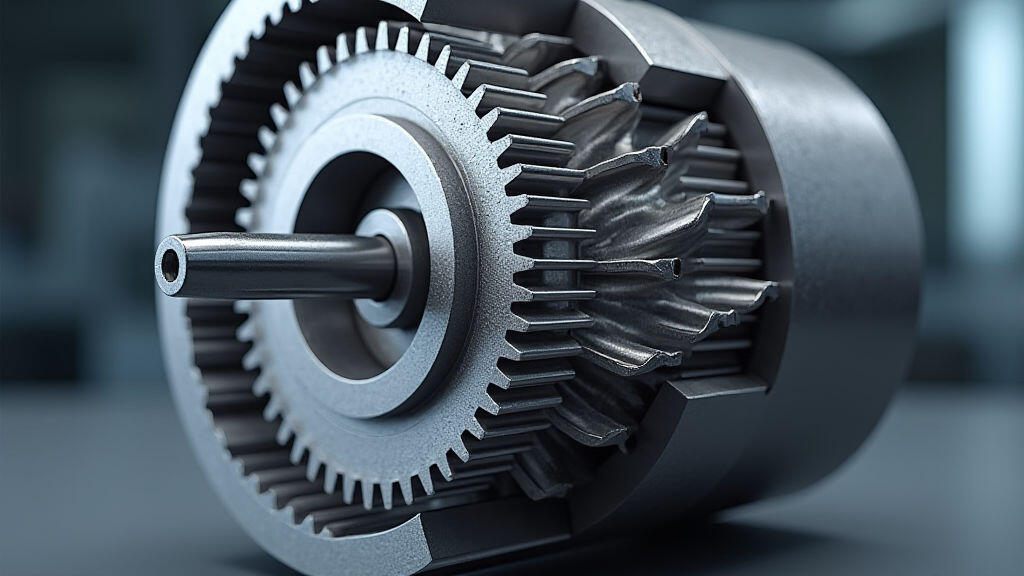

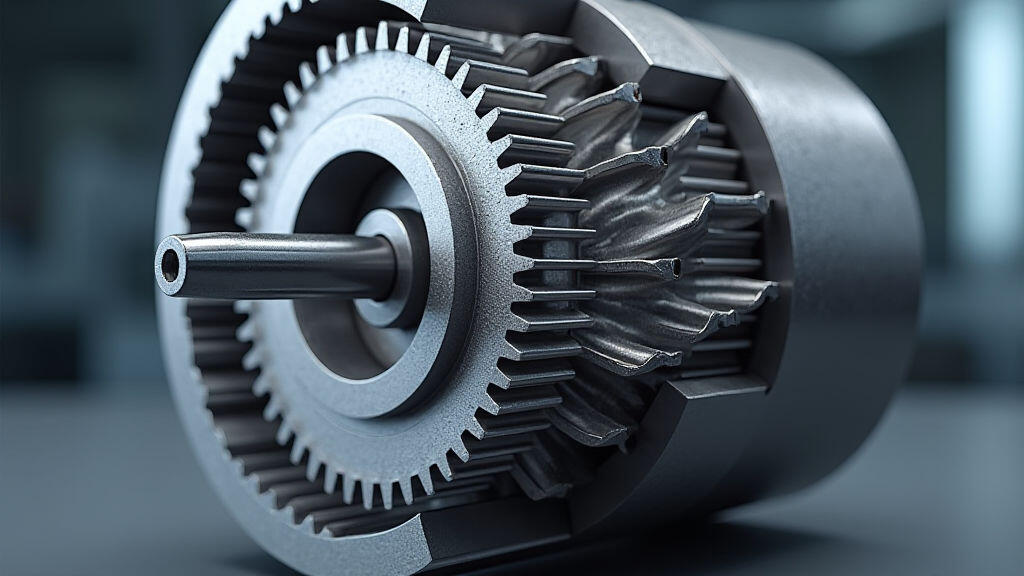

DC gear motors combine a DC electric motor with a gearbox to reduce rotational speed and increase torque. This combination is particularly well-suited for applications demanding high torque at low speeds, a common requirement in manufacturing machinery. There are several types of DC gear motors, each with its own advantages and disadvantages:

Worm Gear Motors: Known for their high gear ratios, self-locking capabilities, and compact design, worm gear motors are ideal for applications requiring precise positioning and holding torque. They are often found in robotics, medical equipment, and automated assembly lines.

Spur Gear Motors: These offer high efficiency and are suitable for applications where speed and precision are paramount. They are commonly used in conveyors, printing presses, and packaging machinery.

Planetary Gear Motors: Planet gear motors provide a high power-to-size ratio, high efficiency, and good torque density. They are often preferred in applications with limited space and high power requirements, such as CNC machines and industrial robots.

Helical Gear Motors: These gears offer smoother operation and higher load-carrying capacity compared to spur gears, making them suitable for demanding applications involving heavy loads and continuous operation.

Choosing the right DC gear motor involves careful consideration of several crucial factors:

Torque Requirements: This is arguably the most important factor. Determine the required torque based on the load the motor will be driving, considering static torque (holding torque) and dynamic torque (torque required for acceleration and deceleration). Underestimating torque can lead to motor stalling and premature failure.

Speed Requirements: Identify the required output speed. The gearbox ratio is directly related to the output speed; a higher gear ratio results in a lower output speed and proportionally higher torque.

Efficiency: Efficiency directly impacts power consumption and operational costs. Higher efficiency motors save energy and reduce heat generation, leading to longer lifespan. Look for motors with high efficiency ratings, ideally exceeding 80% for optimal performance.

Gear Ratio: As mentioned earlier, the gear ratio determines the relationship between input and output speed and torque. The ideal gear ratio is dependent on the application’s demands.

Operating Environment: Consider the environmental conditions where the motor will be used. Factors like temperature, humidity, dust, and vibration can affect motor performance and lifespan. IP (Ingress Protection) ratings provide a measure of the motor’s resistance to dust and water.

Motor Type: Select the DC motor type (brushed or brushless) based on the application requirements. Brushless DC motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors, making them suitable for demanding industrial applications.

Size and Weight: In space-constrained applications, size and weight are critical considerations. Choose a motor with a compact design that meets the application’s physical requirements.

Power Supply: Ensure the motor's voltage and current ratings are compatible with the available power supply.

The performance characteristics of different DC gear motors vary significantly. Here's a comparison of key metrics:

| Metric | Worm Gear Motor | Spur Gear Motor | Planetary Gear Motor | Helical Gear Motor |

|---|---|---|---|---|

| Gear Ratio | High | Low-Medium | Medium-High | Medium |

| Efficiency | Low-Medium | High | High | High |

| Torque Density | Low | Medium | High | High |

| Speed | Low | High | Medium | Medium |

| Noise | Relatively Quiet | Moderate | Relatively Quiet | Quieter |

| Cost | Low | Medium | High | High |

| Maintenance | Moderate | Low | Low | Low |

Example Data:

Worm Gear Motor (Example): A 12V DC worm gear motor with a 100:1 gear ratio can achieve a torque of 0.5 Nm at a speed of 12.5 RPM.

Planetary Gear Motor (Example): A 24V brushless DC planetary gear motor with a 20:1 gear ratio can deliver a torque of 2 Nm at a speed of 120 RPM, while maintaining an efficiency of 90%.

The manufacturing landscape is rapidly evolving with the advent of Industry 4.0. This transformation is heavily influenced by the increasing use of connected devices, data analytics, and artificial intelligence (AI). DC gear motors are now playing a role in these advancements, particularly in predictive maintenance.

By integrating sensors into DC gear motors, manufacturers can collect data on vibration, temperature, current, and other parameters. This data can then be fed into AI algorithms to identify potential faults and predict motor failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and improves overall production efficiency. MES-Drive offers integrated motor monitoring solutions that leverage AI for predictive maintenance, enabling manufacturers to optimize motor performance and lifespan.

Furthermore, the rise of collaborative robots (cobots) necessitates motors that offer precise control and reliable performance. High-efficiency DC gear motors are crucial in cobot applications, minimizing energy consumption and extending battery life.

DC gear motors remain a cornerstone of automation in the manufacturing industry. Selecting the appropriate motor requires a thorough understanding of application requirements and a careful evaluation of performance characteristics. The trend towards Industry 4.0 and the integration of AI-powered predictive maintenance are driving demand for more efficient, reliable, and intelligent motor solutions. MES-Drive is at the forefront of this innovation, offering a comprehensive range of DC gear motors and integrated monitoring solutions designed to optimize motor performance and enable smart manufacturing. As the manufacturing industry continues to embrace digitalization, the role of DC gear motors will only become more critical in achieving peak efficiency, enhanced productivity, and reduced operational costs. The future of DC gear motor technology is inextricably linked to the future of manufacturing itself.

Leave A Reply

Your email address will not be published. Required fiels are marked