Gear motors—compact devices that combine a motor and a gear train—are the unsung heroes of modern automobiles. From power steering to electric parking brakes, these components deliver precise torque and speed control while keeping size, weight, and cost in check. As automotive manufacturers push toward higher efficiency, tighter packaging, and greater reliability, understanding the principles behind gear motor design and how different models perform in real‑world scenarios becomes essential.

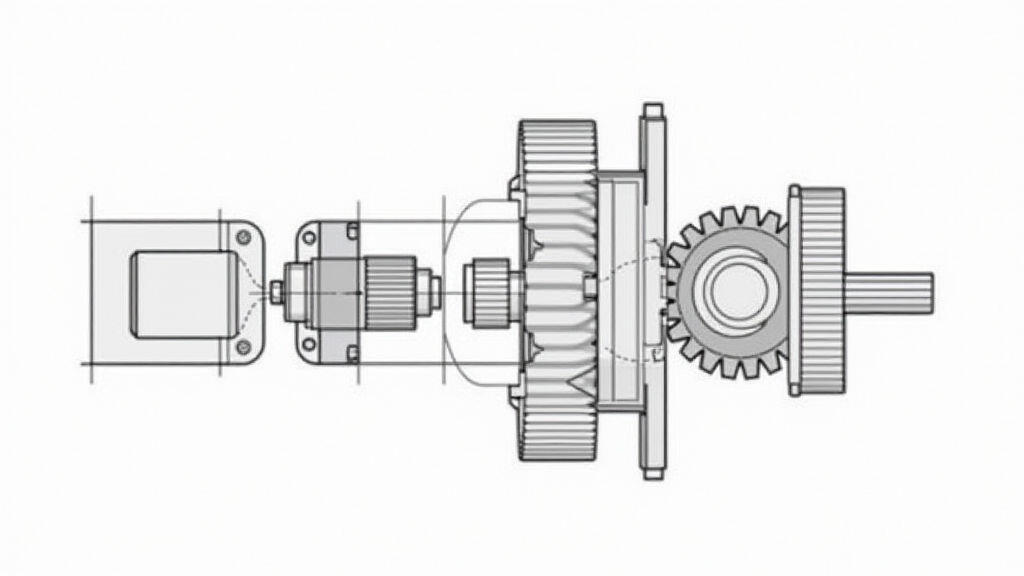

At its core, a gear motor consists of an electric motor (often a brushless DC or permanent‑magnet synchronous motor) and a set of gears that alter the motor’s speed and torque. The motor’s low-speed, high-torque output is then increased or decreased by the gear ratio. The design challenge lies in matching the motor’s electrical characteristics with the mechanical demands of the application.

Three key principles guide gear motor modeling:

Engineers employ several modeling approaches to forecast gear motor performance:

Each method balances detail, accuracy, and computation time, allowing manufacturers to iterate quickly and validate designs before building prototypes.

When comparing gear motor models, several metrics are critical:

| Metric | Why It Matters |

|---|---|

| Rated Torque (Nm) | Determines the motor’s capacity to drive heavy loads such as power steering. |

| Peak Torque (Nm) | Shows that the motor can handle sudden demands, like emergency braking. |

| Efficiency (%) | Higher efficiency translates to less energy waste and longer battery life. |

| Thermal Performance (°C) | A motor that stays cool can sustain high duty cycles. |

| Compactness (kg/m³) | Smaller, lighter motors free up space for critical safety systems. |

| Noise & Vibration | Low acoustic emissions are essential for passenger comfort. |

Below, a simplified comparison distills extensive research conducted on two widely used gear motor families in automotive production: the Model A and Model B.

While Model A edges out slightly in efficiency and heat tolerance, Model B offers superior torque performance at a marginally higher weight. The choice boils down to the application: power steering may prioritize efficiency, whereas an electric parking brake may favor peak torque.

1. Hybrid Power Steering – The semi‑automatic steering system requires a gear motor that can deliver smooth torque strokes while reducing energy consumption. The high‑efficiency Model A is favored in many markets.

2. Electric Vehicle (EV) Seat Adjustment – Seat motors demand precise speed control and wasted-energy minimization. Here, the low noise and compactness of Model A shine.

3. High‑Performance Braking – Some automotive manufacturers employ electrically driven brake calipers. The robustness of Model B, with its higher peak torque and tolerance to heat, makes it a better fit.

As electrification deepens, several trends are set to shape gear motor evolution:

These innovations promise lighter, more efficient, and smarter gear motors that can meet the demanding performance and safety standards of next‑generation vehicles.

In the automotive parts ecosystem, gear motors stand as a testament to engineering finesse—compressing complex electrical and mechanical processes into a compact, reliable package. By mastering modeling principles, focusing on critical performance metrics, and aligning design choices with application needs, manufacturers can select motors that enhance vehicle efficiency, safety, and passenger comfort.

Looking ahead, advances in materials, electronics integration, and manufacturing techniques herald a new era of gear motors that will be lighter, smarter, and more adaptable than ever before. As automotive trends evolve toward higher electrification and autonomy, these motors will play a pivotal role in delivering the seamless performance and reliability that drivers—and the industry at large—now expect.

Leave A Reply

Your email address will not be published. Required fiels are marked