How Robotics Equipment Can Achieve Cost Reduction and Efficiency Improvement Through a Deep Dive into Gear Motors and Their Applications

The robotics industry is experiencing explosive growth, driven by advancements in artificial intelligence (AI), the Internet of Things (IoT), and increasing automation demands across various sectors. From manufacturing and logistics to healthcare and agriculture, robots are transforming how work gets done. A key enabler of this transformation is the sophisticated equipment powering these robots – and at the heart of much of that equipment lies the gear motor. This article delves into how robotics equipment, particularly those utilizing gear motors, can achieve significant cost reduction and efficiency improvements, exploring their applications, benefits, and the evolving landscape shaped by current technological trends.

The Rise of Robotics and the Importance of Gear Motors

Robotics is no longer a futuristic concept; it’s a present-day reality reshaping industries. Companies are adopting robots to address labor shortages, improve precision, enhance safety, and increase production throughput. This shift necessitates robust, reliable, and efficient robotic systems. Gear motors are fundamental components in these systems. They act as the bridge between the motor's rotational output and the required torque and speed for robotic movements. Without efficient gear motors, the overall performance and cost-effectiveness of a robot would be severely compromised.

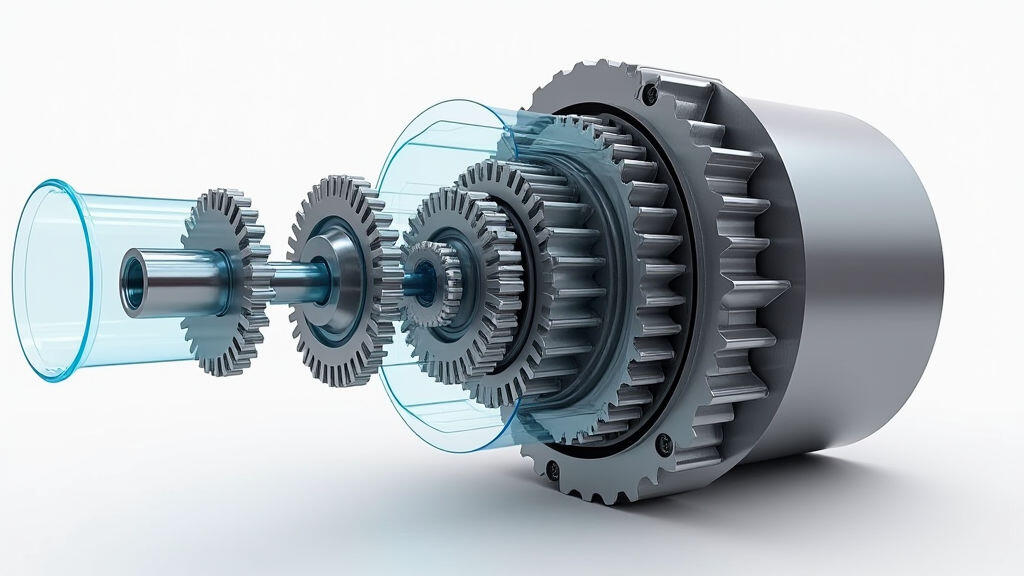

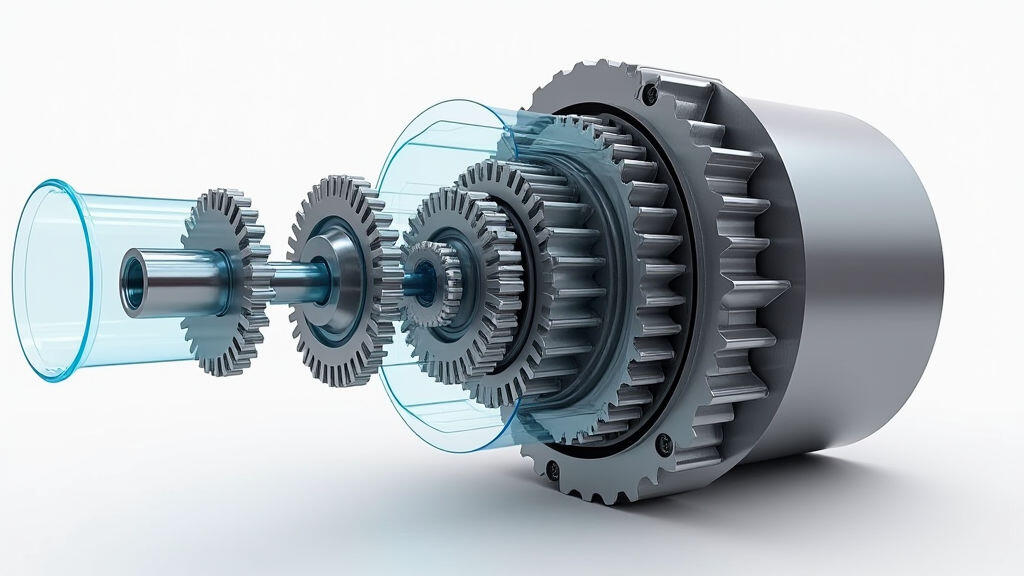

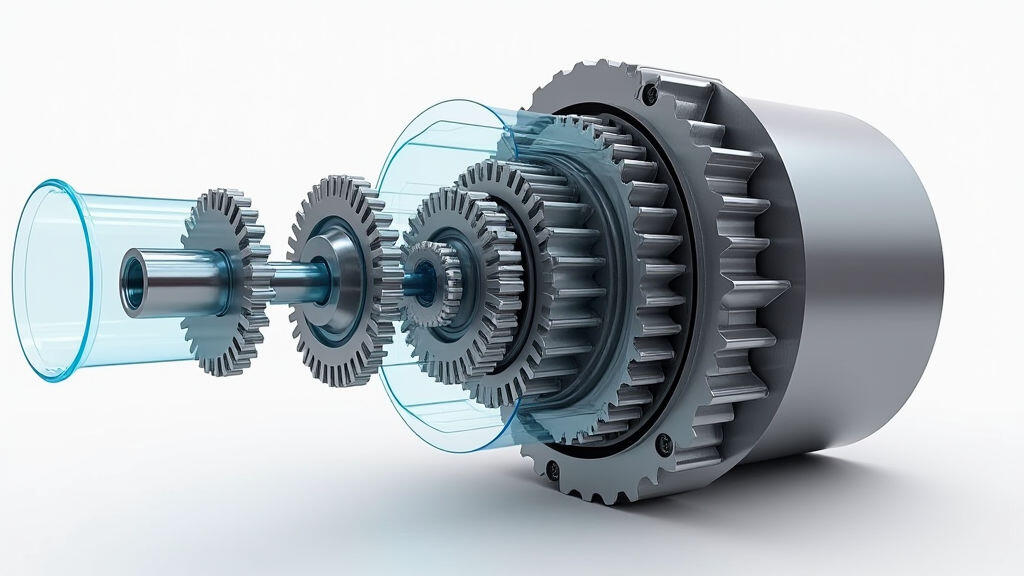

Understanding Gear Motors and Their Types

Gear motors combine a motor with a gearbox to amplify torque while reducing speed. This is essential for many robotic applications where precise control and high force are required. Several types of gear motors are commonly used in robotics:

- Spur Gear Motors: Simple, compact, and inexpensive. Best suited for low-speed, high-torque applications.

- Helical Gear Motors: Offer smoother and quieter operation compared to spur gears, with higher load capacities. Ideal for applications demanding precision and reduced vibration.

- Bevel Gear Motors: Used to transmit power between shafts that are at an angle to each other. Commonly found in robotic arms and steering systems.

- Worm Gear Motors: Provide high gear ratios in a compact package. Offer self-locking capabilities, which are beneficial for holding a load in a stationary position.

- Planetary Gear Motors: Offer high torque density and efficiency. Well suited for applications requiring precise position control.

The choice of gear motor hinges on the specific requirements of the robotic application, including torque needs, speed demands, space constraints, and budget considerations.

Cost Reduction Through Optimized Gear Motor Selection

Lowering the total cost of ownership (TCO) is a primary driver for businesses adopting robotics. Gear motors play a crucial role in achieving this:

- Energy Efficiency: Modern gear motors, especially those utilizing advanced materials and optimized designs, offer significantly improved energy efficiency. This translates to lower electricity bills and reduced operating costs. For instance, implementing a servo motor with an integrated gearbox can reduce energy consumption by up to 30% compared to directly driving a load with a motor.

- Reduced Maintenance: High-quality gear motors are designed for reliability and longevity, minimizing downtime and maintenance expenses. Features like sealed bearings and robust construction contribute to reduced wear and tear. Implementing predictive maintenance strategies, enabled by IoT sensors monitoring gear motor performance, can further minimize unexpected failures.

- Component Consolidation: Integrated gear motors combine the motor and gearbox into a single unit, simplifying system design and reducing the number of components required. This leads to lower assembly costs and improved reliability.

- Optimized Gear Ratio: Carefully selecting the optimal gear ratio avoids over-sizing the motor, leading to lower initial costs and improved efficiency. An appropriately sized gear motor eliminates the waste of power associated with unnecessarily high torque.

Beyond cost savings, gear motors significantly enhance the efficiency and performance of robotic systems:

- Precise Motion Control: Gear motors enable precise control of robotic movements, essential for tasks like assembly, welding, and painting. Advanced motor control algorithms, coupled with high-resolution encoders, allow for accurate position and velocity control.

- Increased Payload Capacity: By amplifying torque, gear motors enable robots to handle heavier payloads without compromising performance. This expands the range of applications and increases productivity.

- Improved Speed and Acceleration: Gear reduction allows for higher torque at lower speeds, enabling faster acceleration and deceleration, resulting in increased throughput.

- Reduced Vibration & Noise: High-quality gear motors, particularly those with helical or planetary gear designs, are designed to minimize vibration and noise, improving the overall robotic system's performance and operator safety.

Current Trends Shaping the Future of Gear Motors in Robotics

Several key trends are influencing the development and adoption of gear motors in the robotics industry:

- Miniaturization: There’s a growing demand for smaller, more compact gear motors to enable the development of smaller and more agile robots. Micro-planetary gear motors are gaining traction for applications in drones, micro-manipulators, and soft robotics.

- IoT Integration: Integrating IoT sensors into gear motors allows for real-time monitoring of performance parameters such as temperature, vibration, and current draw. This data is used for predictive maintenance, performance optimization, and remote diagnostics.

- AI-Powered Motor Control: Artificial intelligence (AI) algorithms are being used to optimize motor control strategies, improving efficiency and performance. AI can dynamically adjust motor parameters based on real-time feedback, adapting to changing load conditions and environmental factors.

- Additive Manufacturing (3D Printing): 3D printing is enabling the creation of custom gear motor components and housings, reducing lead times and enabling rapid prototyping. This facilitates the development of highly specialized gear motors tailored to specific robotic applications.

- Sustainable Materials: Focus on utilizing gear motors made with recycled materials and designs prioritizing energy conservation aligns with growing sustainability initiatives and contributes to the reduction of the overall carbon footprint of robotics applications.

MES-Drive: Leading the Way in Gear Motor Innovation

MES-Drive is at the forefront of gear motor innovation, offering a comprehensive range of high-performance gear motors designed for robotic applications. MES-Drive’s commitment to quality, efficiency, and advanced technology helps companies achieve significant cost reductions and efficiency improvements in their robotic systems. Their gear motors are designed with IoT integration in mind, providing valuable data for predictive maintenance and performance optimization.

Conclusion: Gear Motors - The Engine of Robotic Advancement

Gear motors are indispensable components in modern robotics, playing a critical role in cost reduction, efficiency improvement, and overall system performance. The trends of miniaturization, IoT integration, AI-powered control, and sustainable design are driving continuous innovation in this field. As robotics continues to permeate more aspects of our lives, the demand for high-performance, efficient, and reliable gear motors will only increase. Businesses embracing advancements in gear motor technology, such as those offered by MES-Drive, are poised to gain a competitive edge in this rapidly evolving landscape. The synergy between AI, advancements in gear motor technology, and IoT integration is unlocking new possibilities for automation, enabling more sophisticated, adaptable, and cost-effective robotic solutions – a critical factor for navigating the current economic climate and achieving long-term growth.

Leave A Reply

Your email address will not be published. Required fiels are marked