In the fast‑moving world of robotics, every kilogram saved on the chassis and every watt spared on the power supply translates into clearer profitability and smoother operation. At the heart of most robotic platforms lies the gear motor – a compact powerhouse that turns electrical energy into mechanical motion. While it may seem like just one component among many, the way you choose and configure your gear motors can profoundly impact both the upfront cost and the long‑term performance of your robotic system.

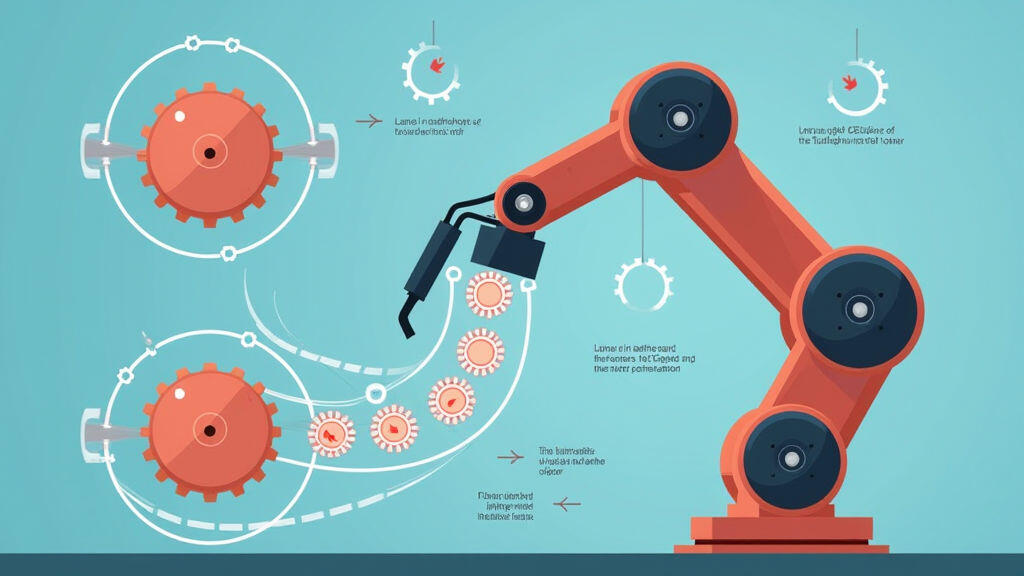

Gear motors are essentially a motor and an integrated gear set combined into a single unit. They provide speed reduction or increase, torque amplification, and typically a simplified interface for the motion controller. In robotic arms, conveyor systems, pick‑and‑place machines, and autonomous vehicles, gear motors translate the controller’s command into precise, repeatable motion. Because they occupy a modest amount of space, they’re ideal for the tight confines of many robotic designs.

Choosing the right gear motor isn’t a one‑size‑fits‑all decision. Think of it like picking the right tool: you need the right balance of strength, speed, size, and durability for the job at hand. Below are the most influential criteria.

1. Reduced Development Time

A well‑fitted gear motor eliminates the need for additional gearing stages, simplifying the mechanical design and speeding up assembly. Fewer custom parts lower procurement costs and reduce setup time on the factory floor.

2. Lower Energy Bills

When a motor’s efficiency matches the load, it draws fewer amps. For a 24‑hour operation, a 0.3 % efficiency improvement per motor can save several thousand dollars annually in industrial settings.

3. Extended Product Life

Choosing a motor that reduces mechanical stress—by providing appropriate torque ratios and better backlash control—lowers wear on gears, bearings, and housings, boosting the lifetime of the entire robot.

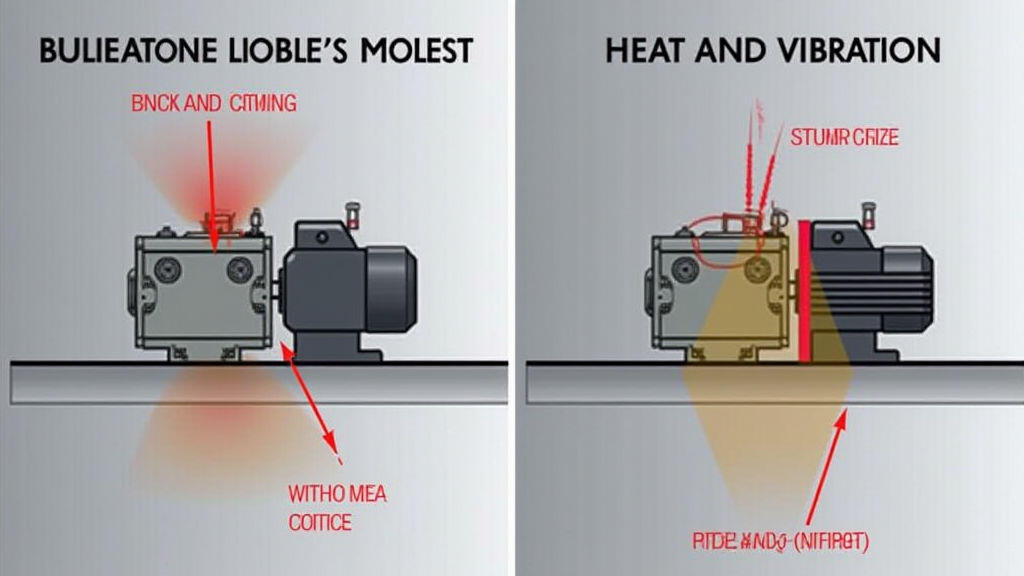

4. Optimized Heat Management

Efficient motors generate less heat, allowing designers to use thinner cooling ducts or even eliminate active cooling in low‑profile robots. This cuts both material costs and operational overhead.

Efficiency is not just about electrical consumption; it encompasses mechanical smoothness, torque accuracy, and control responsiveness. Three practical strategies help you squeeze out every ounce of performance.

One industrial client needed to upgrade its assembly line. The original design used a generic spur‑gear motor that was often running at half its rated speed. After a detailed motor analysis, the team swapped in a compact planetary gear motor with matched torque curves and higher efficiency (95 % vs 89 %).

Results:

The coming years promise further efficiency gains driven by materials science and digital integration.

In robotics, the gear motor is more than a mover—it’s a lever for strategic cost control and efficiency. By thoughtfully aligning torque, speed, efficiency, and reliability with your application, you reduce energy bills, extend component life, and cut down on both initial and ongoing expenses. As smart motors and advanced materials become mainstream, the potential to squeeze even more value from your robotic platforms is only going to grow. Selecting the right gear motor is thus not just a technical decision; it’s a key business lever that can give companies a decisive edge in today’s competitive manufacturing landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked