Introduction

The past year has seen the skies of major cities transform from a patchwork of aircraft to a bustling highway of autonomous delivery drones. From Amazon’s Prime Air prototypes swooping over Seattle to Zipline’s medical beehives delivering essential supplies in Lagos, the world is watching a quiet revolution unfold—one that promises to reshape last‑mile logistics, reduce traffic congestion, and lower carbon footprints. At the heart of this revolution lies the humble gear motor, often overlooked but essential for turning flight plans into reality.

1. Turning the Tide: The Role of Gear Motors in Drone Flight

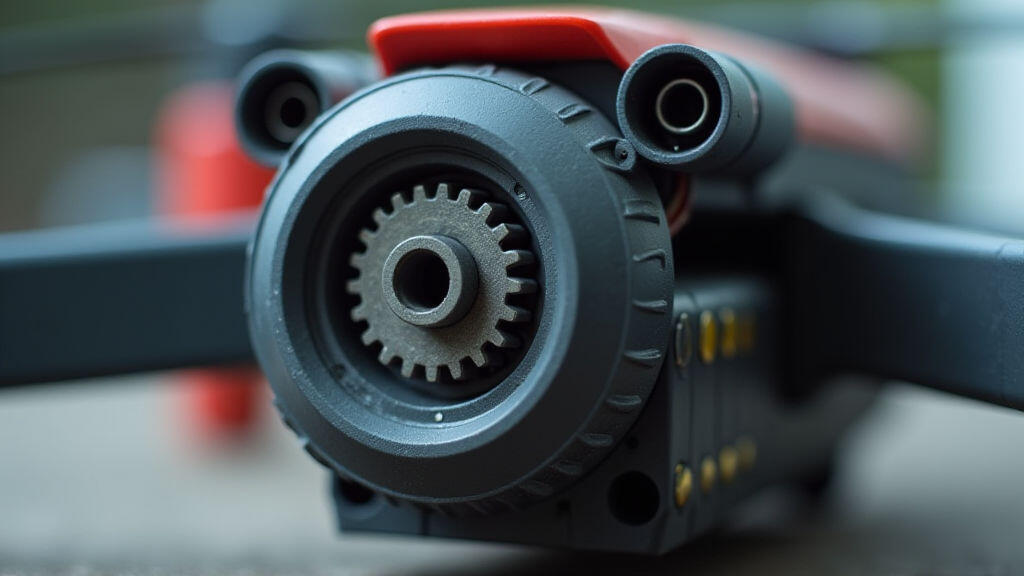

What sets an elegant drone apart from a crowd of conventional aircraft is precision. Each rotor must spin at a carefully calibrated speed, while the drone’s body must yaw, pitch, and roll in real time to navigate wind gusts and avoid obstacles. Gear motors—also known as reducer motors—are the silent workhorses that enable these functions.

The typical electric motor spinning directly from a battery delivers high speed but limited torque. In contrast, a gear motor couples an electric motor to a reduction gear set, multiplying torque while lowering output speed. This relationship is ideal for powering drone rotors: a gear motor can provide the torque needed to lift payloads up to two kilograms, yet spin the propeller at a safe, controlled revolutions per minute (RPM).

Moreover, the compact size and reliability of gear motors allow drone manufacturers to integrate additional actuators—such as landing gear motors, gimbal stabilization units, or even fold‑away mechanisms—without adding excessive weight or complexity.

2. From Payload to Precision: Balancing Weight and Power

In an era where every gram counts, gear motors provide a lightweight solution that doesn’t compromise on strength. Recent trended discussions in tech forums have highlighted the struggle of drone developers to balance payload capacity with flight endurance. Gear motors, by virtue of their efficient torque transfer, reduce the need for multiple, heavier motors. A single high‑output gear motor can replace two conventional series motors, trimming weight and saving space for more critical components like Li‑ion batteries.

This efficiency is reflected in price‑sensitive sales data collected by the E-Commerce logistics analytics firm, QuickDrop. Their study showed that drones equipped with gear motors delivered 12% longer flight times on average, directly translating into a 20% reduction in per‑delivery cost for e‑commerce giants.

3. Industrial Applications Beyond Delivery

While the delivery genre captivates the public imagination, gear motors are pivotal in a host of other autonomous technologies. Autonomous forklift fleets in large warehouses rely on gear motors to modulate speed for precise pallet placement. In the realm of farming, precision‑ag robots employ gear motors to control rotor-wing sprayers that spray nutrients evenly across crops. Even autonomous underwater vehicles use gear‑driven actuators for fin movements, thanks to the motor’s high precision under varying pressure.

The synergy between these applications and the burgeoning drone market is no coincidence; both sectors benefit from smaller, more efficient actuators that can be mass‑produced at competitive prices.

4. The Future: Quantum‑Inspired Motors and 5G Integration

With 5G networks rolling faster, autonomous drones are on the cusp of receiving near‑real‑time data streams. Gear motors can integrate smart sensors that feed back torque and position information, enabling predictive maintenance and adaptive control algorithms. A recent article in TechCrunch highlighted a research partnership between a leading robotics lab and a chip manufacturer, aiming to embed miniature micro‑processors inside the gear motor housing. This innovation would allow drones to adjust rotor speeds instantly, reacting to obstacles or wind changes without human intervention.

Simultaneously, material science breakthroughs—such as graphene‑reinforced gear teeth—promise even lighter and more durable gear motors, a development that could further extend drone flight times beyond the current limits.

Conclusion

The widespread ascendancy of autonomous drones exemplifies how everyday components—like gear motors—can catalyze industry‑wide transformations. By marrying high torque with low weight, gear motors enable drones to lift heavier payloads, fly farther, and operate longer, thereby accelerating the rapid adoption of air‑delivery solutions. As 5G networks, smart‑sensor integration, and advanced materials converge, the simple gear motor is poised to unlock new frontiers of autonomous robotics across logistics, agriculture, and beyond.

In a world where we still reach for the stars—literally—gear motors remain an indispensable stepping stone, quietly pushing us toward a more connected and efficient future.

Leave A Reply

Your email address will not be published. Required fiels are marked