In the fast‑moving world of food processing, plant owners and operators are constantly looking for ways to trim operating costs while boosting productivity. One key player in achieving this balance has emerged from an unexpected source: gear motor manufacturers. These companies, once seen only as suppliers of compact power units, now offer solutions that combine durability, precision, and smart connectivity, delivering measurable savings and performance gains across the entire production line.

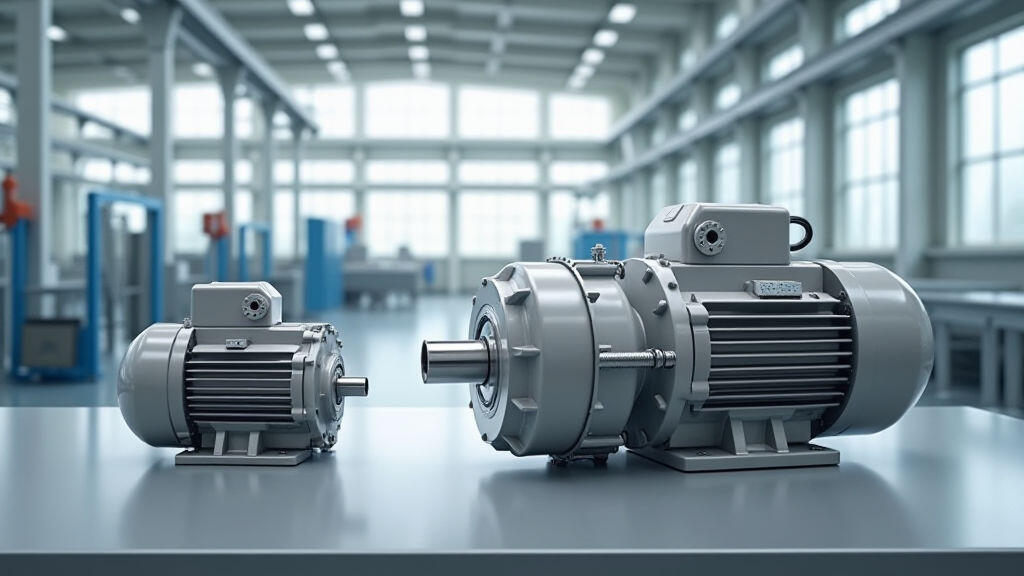

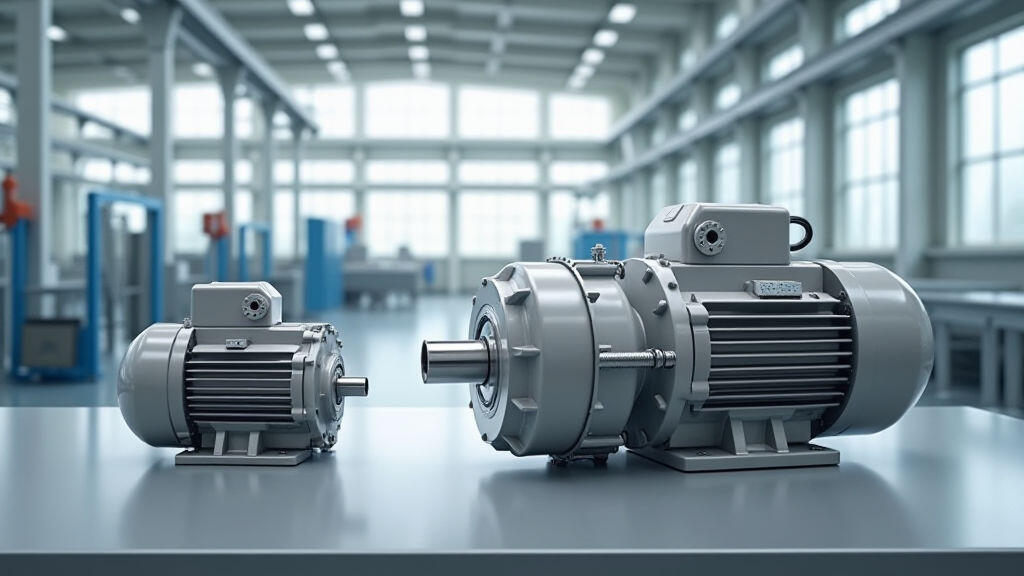

Food plants are complex ecosystems that involve conveyors, mixers, slicers, dehydrators, and countless other pieces of equipment. Each of these machines needs a reliable source of power that can be precisely controlled. Traditional direct‑drive motors often require large housings and generate excessive heat. In contrast, gear motors provide high torque at low speeds in a very compact package, making them ideal for the space‑constrained, hygiene‑critical environments of food production.

Beyond size, gear motors excel in three crucial areas that directly impact cost and efficiency:

Efficiency is the single largest driver of cost reduction in food processing. A gear motor’s high torque‑to‑size ratio means that less electrical power is required to perform the same mechanical work. For example, a conveyor that previously drew 10 kW with a large induction motor can operate on a 4 kW gear motor without loss of performance. When applied across an entire plant—often dozens of conveyance routes—these savings translate into tens of thousands of dollars in annual energy costs.

Moreover, gear motors typically feature advanced soft‑startup capabilities. By gradually ramping up speed, they avoid sudden torque spikes that would otherwise place additional load on the plant’s electrical grid. This reduces wear on both the motor and the supply system, further extending equipment life.

In food processing, downtime is expensive. Each minute of stoppage can lead to significant revenue loss, spoilage, and safety risks. Gear motors benefit from a sealed, straightforward construction that eliminates many of the moving parts that wear out in conventional drives. The rigid gear train offers predictable torque delivery that is easier to monitor and maintain.

Manufacturers now provide diagnostic sensors as part of their motor packages, offering real‑time monitoring of temperature, vibration, and motor current. These data feed into predictive maintenance platforms, allowing operators to catch issues before they cause a breakdown. The result is a steady reduction in unplanned downtime and lower maintenance labor costs.

Today’s gear motor manufacturers are not just power equipment providers; they are digital enablers. By integrating Internet‑of‑Things (IoT) connectivity, gear motors can communicate directly with factory control systems, offering visibility into performance metrics, energy consumption, and fault indicators.

Integration with platforms such as SCADA, MES, and ERP enables a seamless flow of data that supports process optimization. For instance, if a slicer’s motor shows a gradual rise in operating temperature, the system can schedule a maintenance window before the motor fails, preventing product loss and contamination.

Consider a mid‑sized bakery that replaced its 20 conveyor belts’ induction motors with high‑efficiency gear motors. The initial capital expense was a 12% increase in motor cost, but within six months the bakery reported a 9% drop in electricity spend and a 4% reduction in maintenance incidents. The savings, combined with higher throughput due to reliable motor performance, allowed the bakery to increase annual profits by 3%, a return on investment that was reached in under two years.

Sustainability is a trending event that is reshaping the food industry. Consumer demand for clean, green products forces manufacturers to adopt solutions that minimize environmental footprints. Gear motors fit perfectly into this narrative:

Additionally, the small size of gear motors paves the way for modular, reconfigurable production lines. Plant owners can rapidly adapt their equipment to new products or seasonal demand, creating a flexible and resilient operation that is less susceptible to market fluctuations.

Gear motor manufacturers are rewriting the playbook for cost reduction and efficiency in food processing. By offering energy‑efficient, low‑maintenance, and smart‑connected solutions, they enable plants to lower operational expenses, cut downtime, and streamline production workflows. The synergy of compact design, advanced diagnostics, and digital integration not only delivers immediate financial benefits but also positions food processors to meet future sustainability and agility challenges. As the industry continues to evolve, gear motors will remain a critical component for any plant striving to stay competitive and forward‑looking.

Leave A Reply

Your email address will not be published. Required fiels are marked