On October 23, 2025, the automotive world erupted in excitement as major automakers—Volkswagen, Hyundai, and General Motors—launched a wave of high‑performance electric vehicles (EVs). Coupled with “green” rallies across Europe and a record‑breaking production spike announced by Tesla’s Cybertruck, the event signaled a significant shift toward electrified mobility. Among the buzz is a less heralded but equally critical component: the gear motor, or reducer motor. This article explores how the sudden surge in EV demand directly fuels the market for high‑quality gear reducers, the technology that ensures smooth, efficient power delivery from the battery to the wheels.

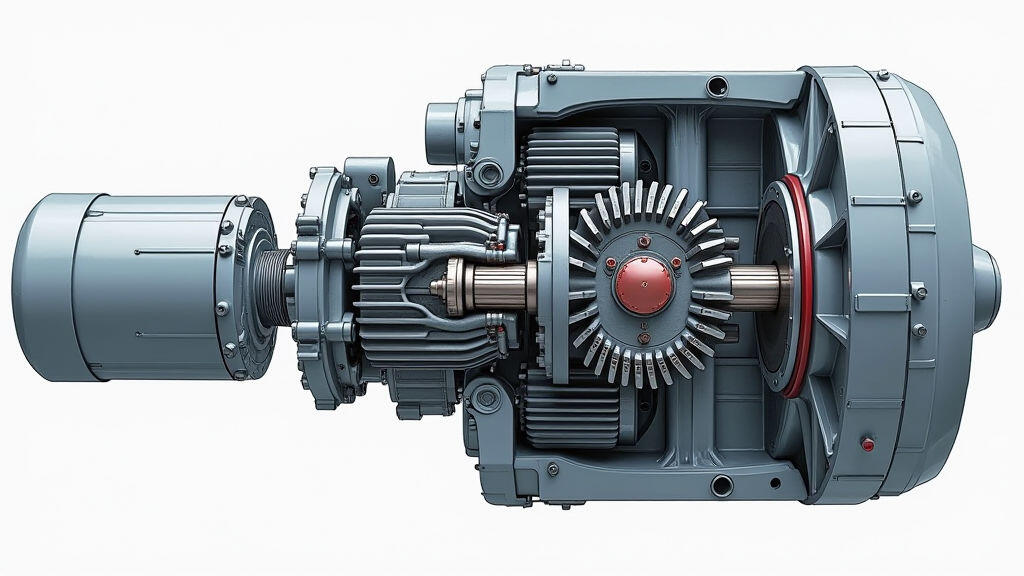

A reducer motor combines a motor—typically a permanent‑magnet or induction motor—with a reduction gearbox in a single, compact housing. By integrating the gear stage directly into the motor, manufacturers can fine‑tune torque and speed outputs for specific applications. In the EV context, this means that the motor can produce the high torque needed for rapid acceleration while reducing the shaft speed so that the drive system can operate optimally and efficiently.

Unlike separate motors and gearboxes, the integrated design offers several advantages:

The newly launched vehicles are not just electric; they are high‑performance. German “Track” models boast acceleration times under 3 seconds, while Hyundai’s AI‑driven models promise instantaneous torque. Such performance demands that every component—from the battery pack to the drivetrain—be pushed to its limits. Gear reducers deliver the necessary torque multiplication, translating the motor’s high‑RPM, high‑torque output into optimal wheel speeds.

Hosting the EV revolution also means managing “power creep”—the gradual increase in power and torque requirements as competitors release more capable vehicles. Gear motors are the quiet workhorses that can be quickly re‑engineered to handle higher loads without wholesale redesign of the vehicle’s architecture. This agility is indispensable to manufacturers trying to meet tight launch schedules and maintain profitability.

Recent R&D efforts in gear reducer design have focused on two key fronts: adding smart control and improving thermal management.

The escalation in gear motor orders has spurred a resurgence of strategic partnerships. German manufacturers like Bosch and Continental are collaborating with Chinese chip and silicon-based production companies to create a hybrid supply chain that balances cost and technology leadership. This cross‑border cooperation accelerates the delivery of gear motors for the on‑going EV production ramp‑up, creating a ripple effect across automotive suppliers.

At the same time, emerging economies—India, Brazil, and Southeast Asia—are stepping into the gear motor game. They host large automotive assembly plants where locally produced gear reducers lower import duties and meet local content regulations, aligning with broader sustainability policies.

The relevance of gear reducers extends past passenger cars. Autonomous delivery robots, e‑scooters, and even electric bicycles incorporate reduced‑integrate motors to deliver efficient torque and extend battery life. For instance, the new Boston Dynamics robot “Stretch” uses micro‑gear reducers that boost payload capacity while keeping the arm’s weight low, illustrating the cross‑industry potential of this technology.

That same technology also taps into the booming “city‑mobility” sector. As the United States unveils a new federal plan to connect metropolitan centers with high‑capacity electric trams, gear motors equipped with regenerative braking can capture waste energy and feed it back into the grid—an advanced feature that engages the growing demand for smart, green infrastructure.

The July 2025 surges in high‑performance EVs demand components that can keep pace with the new performance envelope, and gear reducers fit perfectly into that picture. They enable lightweight, compact, and efficient power transmission that translates the motor’s electrical output into the precise mechanical action required by wheels. As automakers continue to push toward faster acceleration, longer ranges, and smarter vehicles, the demand for sophisticated gear motors will rise correspondingly.

Thus, while EV headlines shout about batteries and autonomous chips, the real workhorse that makes those features possible remains the gear reducer. Its pivotal role across the automotive supply chain, coupled with ongoing innovations, signals a bright future—one that keeps our roads moving, our cities humming, and our sustainability goals moving forward.

Leave A Reply

Your email address will not be published. Required fiels are marked