The past year has seen an unprecedented surge in autonomous delivery robots. From Amazon’s Scout roaming city streets to Alibaba’s Tmall Genie drones and Uber’s new robotaxi prototypes, headlines across tech blogs, CNBC, and social media have been saturated with the buzz surrounding this new frontier of logistics. The episode of TechCrunch Disrupt 2025 highlighted how “robotic delivery isn’t just about innovation; it’s about unlocking a new layer of urban mobility.” In the middle of this excitement lies a quiet hero: the gear motor, also known as a reducer motor, which quietly brings speed, torque, and precision to the kinematics of every autonomous delivery unit. This article explores why gear motors have become indispensable in the autonomous delivery boom, what this means for the market, and how the product may shape our cities in the near future.

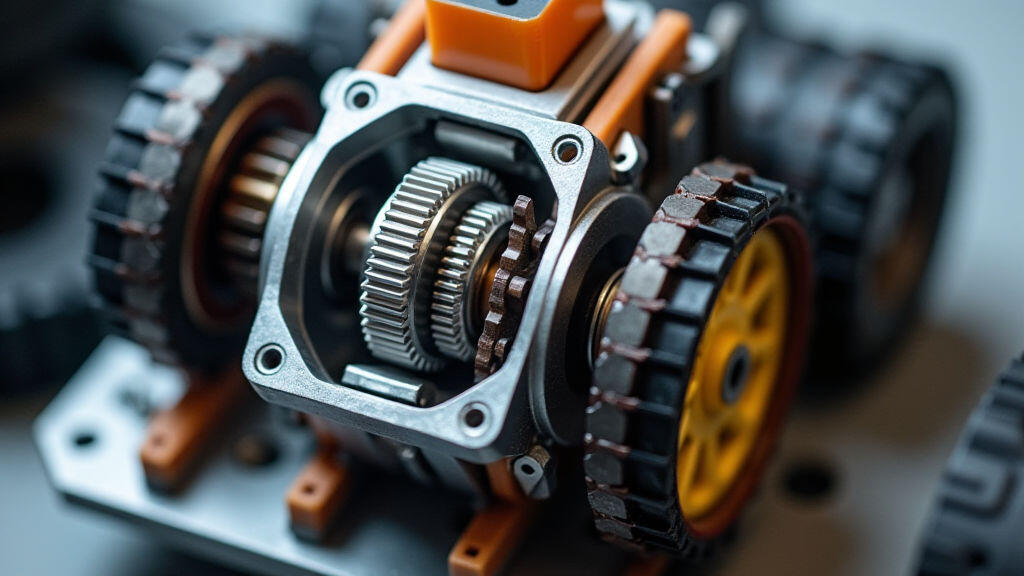

At its core, autonomous delivery is simply a complex choreography of sensing, computation, and actuation. Sensors detect pavement, pedestrians, and obstacles; algorithms decide the best route; and actuators—primarily motors—move the robot forward, turn, and sometimes lift a package onto the sidewalk. When it comes to electricity‑powered propulsion, two things matter most: torque (the pulling force required to get a robot moving) and speed (how fast that movement can be). Gear motors satisfy both demands, converting high‑speed, low‑torque electric motor output into low‑speed, high‑torque motion that can get a robot onto a curb, over uneven sidewalks, or through narrow alleys.

“Every autonomous delivery robot we’ve built uses a gearmotor in its drivetrain,” says Liyuan Chen, lead mechanical engineer at iRobot (the company behind the Scout prototype). “Without the reduction in speed and the increase in torque that a gearmotor provides, we wouldn’t be able to navigate real‑world environments reliably.” This everyday truth serves as the foundation for why gear motors are now a hot commodity in robotics circles.

The market for autonomous delivery robots reached an estimated USD 1.1 billion in 2024, with forecasts predicting doubling of that value by 2027. And a large proportion of that spend is dedicated to the underlying mechanical components—gear motors being the most demanded part. This rise is partially driven by the fact that drivers—whether human or algorithmic—require precision control to avoid hazards. Gear motors offer an excellent ratio of torque to weight, which drastically reduces the power needed to maneuver a delivery robot. That translates into longer battery life, higher throughput, and ultimately lower operational costs for fleets.

According to a recent Gartner research brief, “gear motors for robotics, if they are well engineered, are typically rated at 5–10 hp and have a geared ratio from 10:1 to 30:1.” Such specifications directly impact the robot's agility, allowing it to change direction in under a second, climb steps, and disengage safely from the robot’s own mechanical stress. Companies that have partnered with Gear Motor manufacturers are now reporting a 20 % decrease in energy consumption per kilometer compared to earlier models that used worm gears or direct drives.

While the delivery robot market is the current headline-grabber, the same gearmotor technology is being incorporated into other sectors propelled by the same “autonomous” trend. In warehouse automation, robots that sort packages benefit from gear motors that can handle heavy loads at low speeds; in medical logistics inside hospitals, a gentle yet strong torque is required to carry sterile supplies across bustling corridors; and in smart city infrastructure, autonomous street sweepers and trash recyclers rely on the same principle.

“We’re finding that our gearmotor lines that were initially produced exclusively for heavy-duty equipment have found resonance in a variety of new fields,” says Julia Martín, product manager for industrial robots at Gear Motors, Inc. “The versatility of the reducer design is like an artist’s paintbrush—it can be mixed and adapted to many settings, whether it’s a single‑motor scooter, a robot arm, or an autonomous delivery burrow.” This cross‑industry spillover has a cascading effect, pushing the whole component supply chain to evolve—faster, lighter, and smarter gearmotors that integrate sensors and firmware monitoring straight from the factory.

Smart gear motors are no longer just about mechanical advantage. Manufacturers now embed small memory chips that record motor performance metrics: torque, temperature, vibration. Through IoT protocols—Bluetooth Low Energy, Wi‑Fi, or industrial‑grade 5G—this data can feed into machine‑learning models that predict maintenance windows, reconfigure torque curves on the fly, or adjust motor speed to conserve power.

Fast‑growing start‑ups such as VelociTech and GearSense are partnering with gearmotor OEMs to provide “digital twin” services for autonomous fleets. The result is a closed‑loop system wherein each motor reports to a central cloud platform, confidently informing fleets that all drives are operating within the prescribed limits. The synergy of reliable gear motors and data analytics has been touted as one of the key enabling factors for safe, mass‑deployed autonomous robots.

The push for greener cities is forcing companies to reduce the freight weight and battery energy consumption of autonomous delivery robots. At the same time, the need for miniaturization—think delivery robots that can squash in a delivery locker or glide under a traffic-lamp—has the gearmotor market looking to create smaller yet equally powerful units. Recent prototypes use magnetic flux concentrators and advanced metallurgy to push the torque density 25 % higher than older designs while keeping the weight below 8 kg.

Another future angle is greening the production process. Gear motors that use low‑VOC plastics, recyclable brass or titanium alloys, and lower energy consumption in manufacturing are receiving stronger demand from ESG‑conscious logistics operators. The combination of mechanical efficiency with sustainable materials could be the winning line for companies looking to differentiate in the competitive autonomous delivery arena.

From the flavor of an expedited lunch order on the pavement to vital patient drops in hospitals, gear motors have quietly become the beating heart of autonomous logistics. Their ability to translate electric power into precise, high‑torque movement enables autonomous delivery robots to navigate our streets safely, efficiently, and with minimal environmental impact. As demand for autonomous solutions grows, so too will the responsibility of gear motor manufacturers to evolve with new materials, smarter integration, and stronger performance standards.

In a world where milliseconds can save time and thousands of kilograms can reduce carbon footprints, the gear motor’s simple yet elegant design remains a cornerstone of the autonomous revolution. In picking up a package on a busy sidewalk, you’re not just witnessing the future of delivery—you’re feeling the power of a gear motor propelling that moment into existence.

Leave A Reply

Your email address will not be published. Required fiels are marked