As automation pushes the boundaries of modern manufacturing, robotics production lines demand higher performance and greater sustainability. Central to this evolution are gear motors—compact power units that can translate electric drive into precise, high‑speed motion while minimizing energy waste. This article explores the fundamentals of gear motor operation, explains how gear ratios enhance speed and efficiency, and highlights practical ways to integrate these motors into robotics lines that meet today’s Industry 4.0 standards.

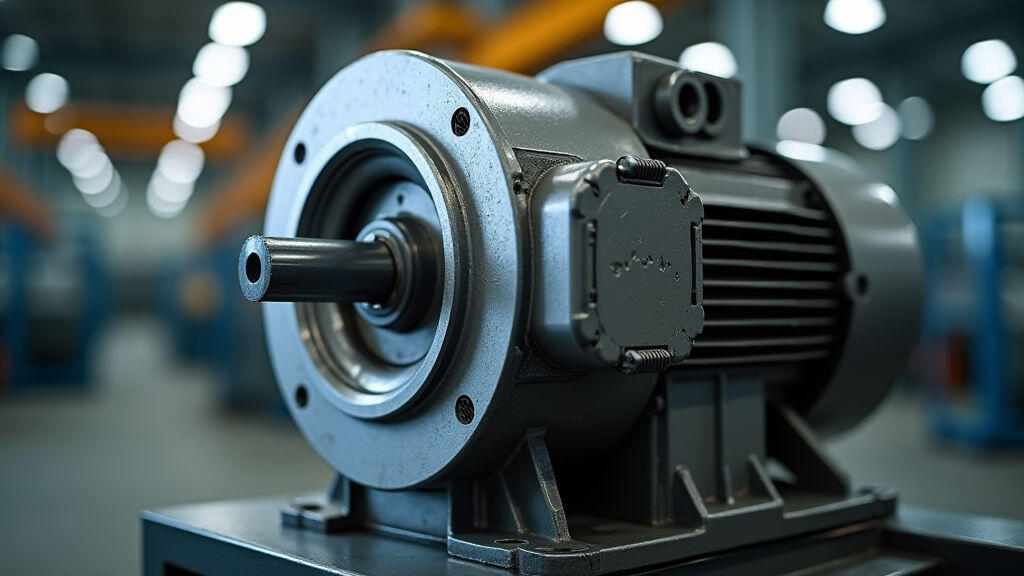

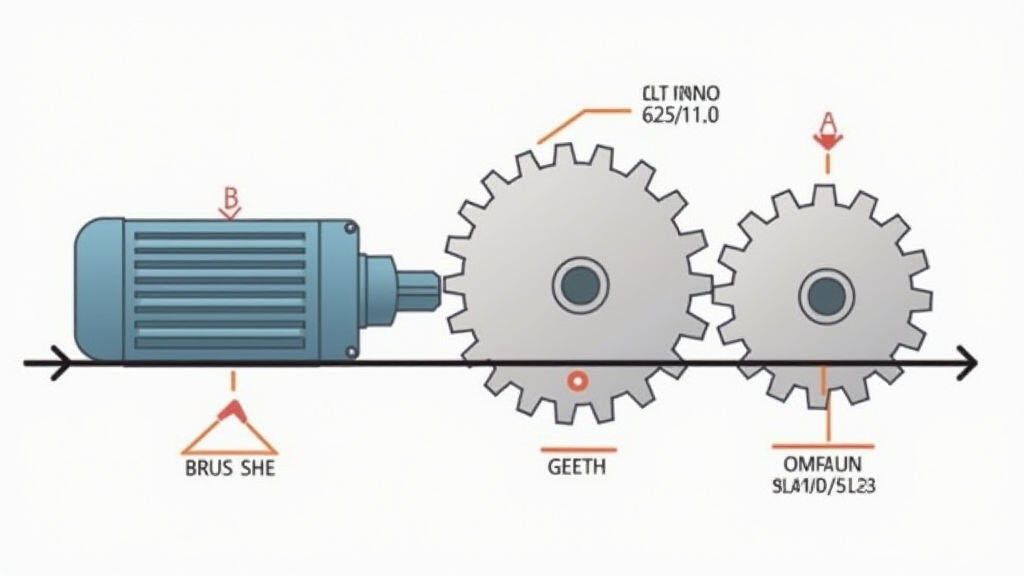

A gear motor combines a rotary actuator—usually an electric motor—with an arrangement of gears that transforms the motor’s speed and torque into the required output for a specific machine. Unlike a simple motor, the gear train tailors the motor’s output to match the mechanical demands of robots, conveyors, or pick‑and‑place arms.

Key attributes of a gear motor include:

The rating of a gear motor is expressed in terms of its speed reduction factor or gear ratio—e.g., a 50:1 gearbox turns a 3000 rpm motor into a 60 rpm output shaft. By selecting the right ratio, engineers can achieve target speeds for robotic joints while preserving torque for heavy payloads.

Speed is not the only benefit; the correct ratio can also help to optimize** the motor’s efficiency curve. Electric motors are most efficient near their rated speed; pushing a motor far above or below that point increases losses. Gearing the drive so the motor runs near its optimal speed can result in a 5–10 % reduction in electrical consumption—critical over long production hours.

Implementing these measures can lead to a 20–30 % overall reduction in the energy footprint of a robotic cell.

Modern robotics cells often combine multiple degrees of freedom—rotary, linear, and complex curved axes. Gear motors serve as the workhorse for each axis due to their modularity.

By adhering to these integration practices, factories can maintain clean, efficient production lines that adapt quickly to new product demands.

Industry 4.0 envisions factories that are connected, autonomous, and self‑optimizing. Gear motors positioned at the heart of these systems become data sources. Sensors can transmit torque, temperature, and vibration in real time, enabling predictive maintenance and energy management algorithms. This smart approach transforms gear motors from passive actuators to active participants in future‑proof production.

In 2023, a mid‑sized electronics plant increased its robotic line throughput by 25 % while reducing energy consumption by 18 % after switching to a new generation of brushless gear motors. The new motors matched the existing robotic joints’ torque needs but operated at a higher speed, thereby sharpening the production cycle. The added temperature sensors fed into a cloud‑based monitoring platform, allowing operators to spot and correct gear wear before any downtime occurred.

The simple yet powerful concept of gear motors—combining a motor with an engineered gear train—offers a reliable pathway to higher speed and energy efficiency in robotics manufacturing. By selecting the right gear ratios, employing high‑efficiency motors, and integrating smart sensors, production lines can achieve faster cycle times, lower power consumption, and greater adaptation to changing product demands. As smart factories become the norm, gear motors will continue to evolve into more intelligent, data‑driven systems, unlocking new levels of productivity and sustainability.

Investors and manufacturers who focus on advanced gear motor technologies position themselves on the cutting edge of the next industrial revolution, ensuring that robotics production lines remain both fast and responsible for the planet’s resources.

Leave A Reply

Your email address will not be published. Required fiels are marked