Modern packaging lines are the backbone of global supply chains, ensuring products reach consumers quickly and safely. As consumer demands for speed, flexibility, and sustainability grow, manufacturers are turning to high‑performance gear motors to drive the next wave of packaging equipment upgrades. This article outlines practical configuration strategies that gear motor manufacturers can employ to meet these evolving needs, making packaging systems smarter, faster, and more energy‑efficient.

Before diving into motor specs, ask the end user what they want to achieve. Is the goal to increase throughput by 20 %? Reduce packaging errors by automating a specific step? Or shift to eco‑friendly, lighter materials that require gentler handling? A clear vision guides the motor selection and drives the design of the control system.

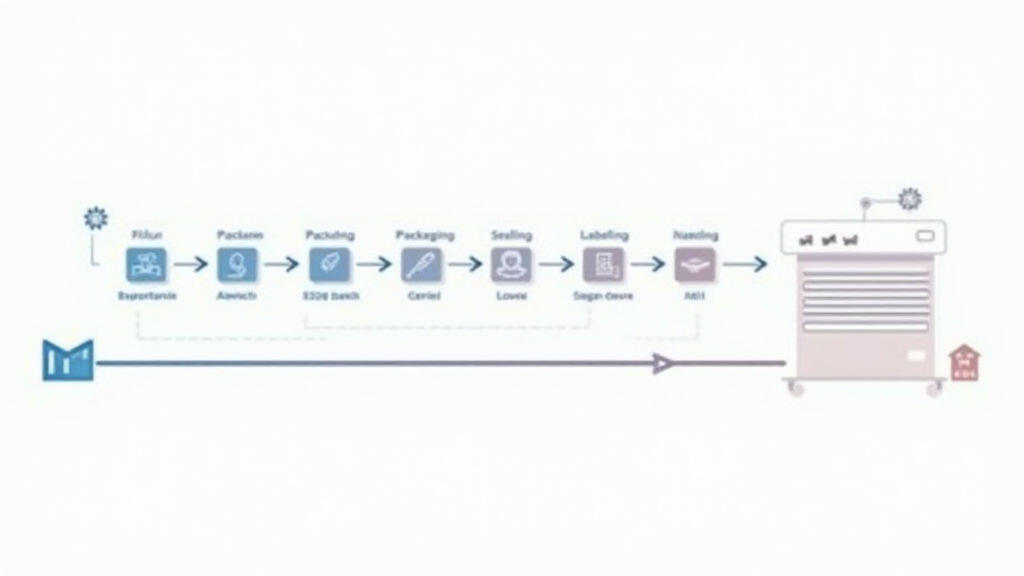

Visualizing the packaging sequence—fill, seal, label, inspect, and depack—helps identify which steps demand high torque, which need rapid acceleration, and where fine speed control is critical. Map these needs to motor performance attributes and you’ll see exactly which gear motor configurations fit best.

Gear motors come in several families—planetary, worm, helical, and spur. Each offers a unique blend of torque, speed, reliability, and packaging‑specific benefits.

When configuring a motor subsystem, consider the gear ratio required to match the mechanical load. High ratios provide torque but reduce speed; balancing these factors is key to achieving the packaging line’s desired throughput.

Today’s packaging equipment is not just mechanical; it’s data‑centric. Modern gear motor configurations should include:

By coupling gear motors with smart leads, manufacturers can transform a conventional line into a flexible, context‑aware production system.

Packaging line upgrades often aim to meet new sustainability targets. Gear motor manufacturers can help by:

Low‑maintenance gear designs also cut downtime, extending the motor’s useful life and making the investment more attractive.

Packaging needs evolve. A company may start with a single conveyor system but later add automated stacking or robotic gripping. Gear motor manufacturers should develop modular units that can be stacked or replaced without redesigning the entire drive chain.

Successful upgrades happen when gear motor teams and packaging engineers sit together during the early design stages. Co‑design workshops ensure:

Such collaboration builds trust and speeds the time‑to‑market for upgraded lines.

Upgrading packaging equipment is no longer just about installing faster machinery; it’s about integrating gear motors that blend torque, precision, smart control, and energy efficiency. By aligning motor type and drive strategy with the packaging process vision, embracing IoT connectivity, focusing on lifecycle cost savings, and fostering collaborative co‑design, manufacturers can unlock significant throughput gains, reduce waste, and meet the rising demands for sustainable packaging solutions. As Industry 4.0 continues to reshape the manufacturing landscape, gear motor manufacturers who adopt these configuration strategies will be well positioned to lead the next generation of high‑performance, intelligent packaging lines worldwide.

Leave A Reply

Your email address will not be published. Required fiels are marked