The Growing Demand for Precision and Efficiency in Agriculture Drives Gear Motor Innovation

The agricultural industry is undergoing a significant transformation, driven by the need for increased efficiency, precision, and sustainability. Modern farming practices increasingly rely on advanced machinery equipped with sophisticated systems. At the heart of many of these systems are gear motors – crucial components responsible for transmitting power and providing controlled rotational motion. As agricultural machinery upgrades accelerate, gear motor brands face the challenge of adapting their configuration strategies to meet the evolving demands of this dynamic sector. This article will explore key configuration strategies for gear motor brands targeting agricultural machinery equipment upgrades, analyzing trends, challenges, and opportunities in this rapidly growing market.

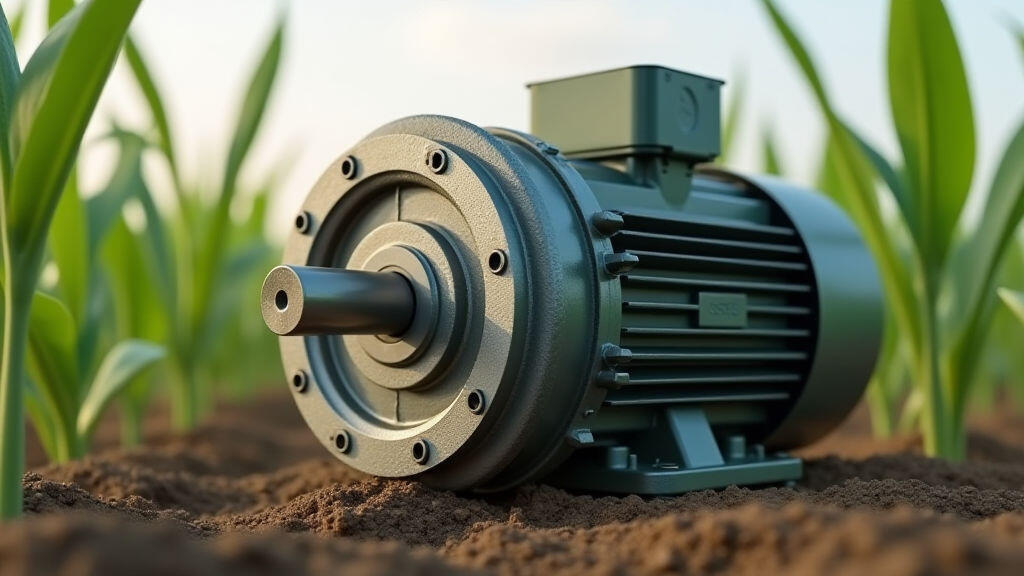

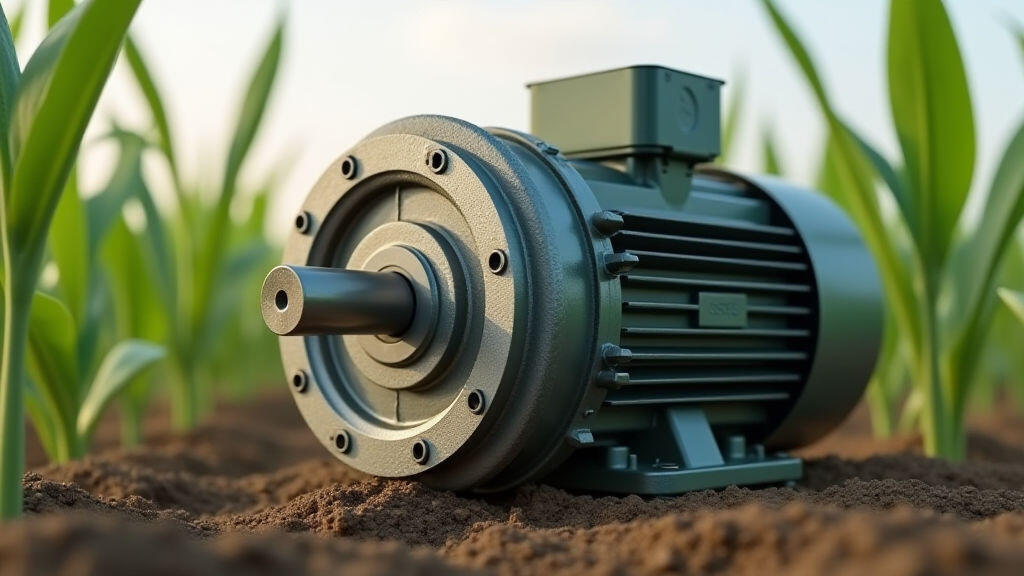

The Role of Gear Motors in Modern Agricultural Machinery

Gear motors are not simply power sources; they're integral to the functionality and performance of modern agricultural equipment. Consider the widespread adoption of precision agriculture techniques – GPS-guided tractors, automated harvesting systems, robotic weeding machines, and advanced irrigation systems – all heavily rely on reliable and efficient gear motors. Common applications include:

Hydraulic Systems: Powering implements like plows, cultivators, and sprayers.

Conveyors and Material Handling: Moving crops, feed, and other materials.

Variable Frequency Drives (VFDs): Providing precise speed control for pumps, fans, and other actuators.

Automated Steering and Control Systems: Enabling autonomous operation of tractors and other vehicles.

Harvesting Equipment: Controlling the speed and precision of cutting and threshing mechanisms.

The increasing complexity of these applications necessitates gear motors that can deliver high torque, precise control, durability, and resistance to harsh environmental conditions often encountered in agricultural settings.

Key Configuration Strategies for Gear Motor Brands

To effectively capitalize on the trend of agricultural machinery upgrades, gear motor brands must adopt strategic configuration approaches focused on key performance characteristics:

Enhanced Durability and Reliability: Agricultural machinery operates in demanding environments – exposed to dust, moisture, extreme temperatures, and vibrations. Gear motor configurations must prioritize robust design, employing materials and coatings resistant to corrosion and wear. Sealed designs, hardened gears, and heavy-duty bearings are essential. Brands should consider offering extended warranties and comprehensive after-sales support to demonstrate commitment to long-term reliability.

Optimized Efficiency and Power Density: Fuel efficiency is a critical concern for farmers. Gear motors with high efficiency ratings translate directly into reduced fuel consumption and lower operating costs. Compact designs with high power density are also desirable, enabling integration into space-constrained machinery. Advanced gear designs, such as helical gears or planetary gearboxes, can improve efficiency and reduce noise. Variable speed options are becoming increasingly popular, allowing for optimized power delivery based on specific task requirements.

Precision Control and Performance: Precision agriculture demands precise control over machine movements. Gear motors should offer accurate speed and torque control, minimizing slippage and ensuring consistent performance. Integration with modern control systems – including CAN bus, Ethernet, and other communication protocols – is becoming standard. Advanced sensor technologies can provide real-time feedback, enabling closed-loop control systems for enhanced accuracy.

Customization and Modular Design: A one-size-fits-all approach is insufficient in the diverse agricultural machinery market. Gear motor brands should offer customizable configurations to meet the specific requirements of different applications. Modular designs allow for easy integration and replacement, reducing downtime and maintenance costs. Standardized mounting options and readily available accessories also enhance flexibility.

Connectivity and Data Integration: The rise of the "connected farm" necessitates gear motors that can be integrated into data-driven systems. Implementing sensors to monitor performance parameters like temperature, vibration, and lubrication levels allows for predictive maintenance and optimized operation. Connectivity platforms enable remote monitoring, diagnostics, and software updates, further enhancing efficiency and reducing downtime.

Challenges and Opportunities

Gear motor brands face several challenges in the agricultural machinery market:

Price Sensitivity: Agricultural equipment is often price-sensitive, requiring brands to offer competitive pricing without compromising quality or performance.

Complexity of Integration: Integrating gear motors into complex machine systems requires strong technical support and collaborative relationships with equipment manufacturers.

Evolving Regulatory Requirements: Increasingly stringent environmental regulations are driving demand for more energy-efficient and environmentally friendly solutions.

Competition: The gear motor market is competitive, with numerous players vying for market share.

However, these challenges also present significant opportunities:

Growing Demand for Precision Agriculture: The expansion of precision agriculture is creating a surge in demand for high-performance, reliable gear motors.

Increasing Focus on Sustainability: The trend towards sustainable farming practices is driving demand for energy-efficient solutions.

Technological Advancements: Advances in materials science, gear design, and control systems are enabling the development of more powerful, efficient, and reliable gear motors.

Collaboration and Partnerships: Building strong partnerships with equipment manufacturers can provide access to valuable market insights and ensure product alignment with evolving needs.

Conclusion: A Future Powered by Intelligent Gear Motors

The agricultural machinery equipment upgrades market is poised for continued growth, driven by the increasing adoption of precision agriculture and the need for more efficient and sustainable farming practices. Gear motor brands that proactively embrace the configuration strategies outlined in this article – focusing on durability, efficiency, precision, customization, and connectivity – will be best positioned to capitalize on this trend. The future of agriculture is inextricably linked to intelligent, adaptable, and reliable gear motor technology. Brands that invest in research and development, cultivate strategic partnerships, and prioritize customer needs will play a crucial role in powering the next generation of agricultural machinery, ensuring a more productive and sustainable food supply. The integration of IoT technologies and predictive maintenance capabilities within gear motors presents a particularly exciting area for future development, promising to revolutionize farm operations and optimize resource utilization.

Leave A Reply

Your email address will not be published. Required fiels are marked