The logistics industry is undergoing a seismic shift. Driven by e-commerce boom, increasing customer expectations for faster delivery, and the relentless pursuit of efficiency, companies are rapidly implementing automation across their warehouses, distribution centers, and fulfillment networks. Conveyor systems are at the heart of this transformation, and their smooth, reliable operation hinges on a critical component: the gear motor. Selecting and matching the right gear motor isn’t just a technical detail; it’s a strategic decision that directly impacts operational costs, throughput, and overall system performance. This guide will explore the pivotal role gear motor selection plays in logistics and conveying automation upgrades, examining key factors, common pitfalls, and future trends.

The logistics sector is experiencing unparalleled growth, placing immense pressure on existing infrastructure. Automation offers a direct solution to address rising demands and challenges like labor shortages, increased order volumes, and the need for enhanced accuracy. Conveyor systems are central to this automation revolution. They facilitate the efficient movement of goods, minimizing manual handling, reducing errors, and optimizing space utilization. From simple belt conveyors to sophisticated automated guided vehicles (AGVs) powered by complex conveyor networks, the possibilities are vast. Furthermore, the rise of AI-powered warehouse management systems (WMS) and robots is further amplifying the reliance on precise and dependable conveyor systems to physically execute the instructions generated by these intelligent systems.

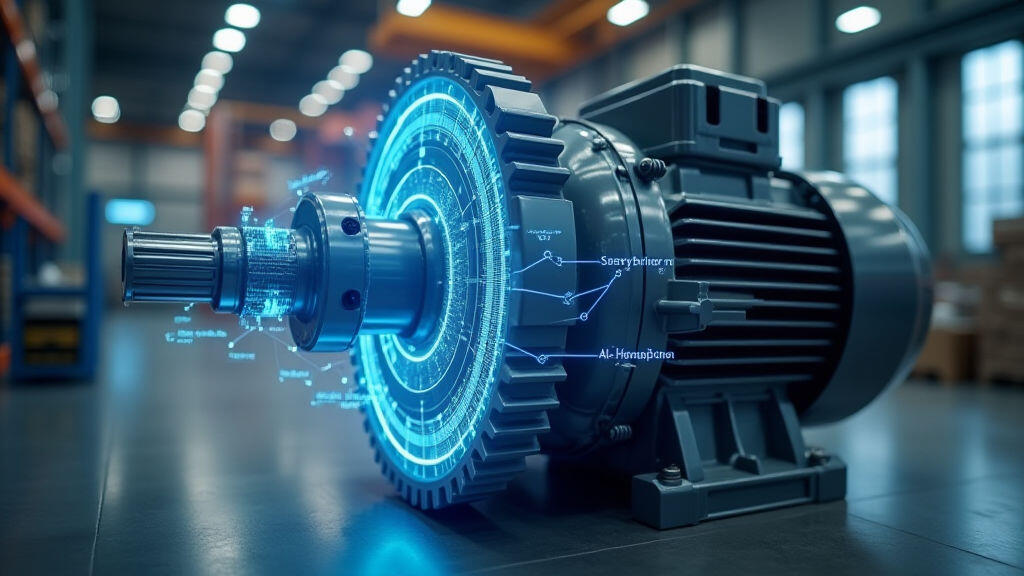

Gear motors are specialized electric motors integrated with gearboxes. This combination provides several critical advantages for conveying applications:

Choosing the right gear motor requires careful consideration of several factors. Ignoring any of these can lead to performance issues, premature failure, and costly downtime.

1. Load Requirements: This is the most fundamental consideration. Calculate the total load (including the weight of the conveyed goods, any inclines, and frictional losses) that the motor and gearbox must handle. Don't forget to factor in potential increases in load as your business grows. Consider both starting torque (the torque required to initiate movement) and running torque (the torque required to maintain speed under continuous operation).

2. Speed and Acceleration: Determine the required conveyor speed and the permitted acceleration/deceleration rates. Different products and processes have different speed requirements. High-speed conveyors are common in e-commerce fulfillment, whereas slower speeds might suffice for handling bulky items.

3. Efficiency: Efficiency directly impacts operating costs. Higher efficiency gear motors minimize energy consumption, reducing electricity bills and lowering the environmental footprint. Look for motors with high efficiency ratings (IE3 or IE4 are common standards).

4. Duty Cycle: Consider the operational hours per day and the frequency of starts and stops. A continuous duty cycle demands a motor with robust construction and adequate cooling.

5. Environmental Conditions: The environment in which the conveyor system operates (temperature, humidity, dust, corrosive substances) must be considered. Motors designed for harsh environments require special sealing and protection.

Simply selecting a gear motor with the right torque and speed isn’t enough. The motor and gearbox must be matched to the specific conveyor system design to achieve optimal performance and longevity.

1. Gear Ratio: The gear ratio determines the relationship between motor speed and output speed. An appropriate gear ratio ensures that the conveyor belt operates at the desired speed, while maintaining sufficient torque. Incorrect gear ratios can lead to motor overheating, belt slippage, and reduced efficiency.

2. Gearbox Type: Various gearbox types, such as helical, spur, and worm gearboxes, are available, each with its own advantages. Helical gearboxes are generally preferred for higher speeds and smoother operation. Worm gearboxes offer high gear ratios in a compact package.

3. Motor Type: AC induction motors are commonly used in logistics applications due to their reliability and affordability. However, permanent magnet synchronous motors (PMSMs) are gaining popularity because of their higher efficiency and improved power density.

4. Redundancy and Reliability: For critical applications where downtime is unacceptable, consider implementing redundant motor systems. This ensures that the conveyor system remains operational even if one motor fails.

The future of gear motor technology is focused on intelligence and connectivity. Smart gear motors equipped with sensors and embedded processors can monitor key parameters such as temperature, vibration, and current draw. This data can be used for predictive maintenance, enabling companies to identify potential problems before they lead to downtime. MES-Drive, for example, offers gear motors with integrated IoT capabilities, providing real-time performance data and facilitating remote diagnostics. This aligns perfectly with the broader trend towards Industry 4.0 and smart manufacturing in the logistics sector.

Gear motor selection and matching are undeniably crucial for successful logistics and conveying automation upgrades. In an era of increasing efficiency demands and technological advancements, choosing the right gear motor isn't merely a technical decision; it's a strategic investment. By carefully considering load requirements, speed, efficiency, and environmental conditions, and by embracing intelligent motor technologies like those offered by MES-Drive, logistics companies can ensure their conveyor systems operate reliably, efficiently, and sustainably. As AI, robotics, and WMS become increasingly integrated into warehouse operations, the demand for robust and intelligent gear motor solutions will only continue to grow. Therefore, understanding the nuances of gear motor selection is no longer optional – it’s essential for staying competitive in the rapidly evolving logistics landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked