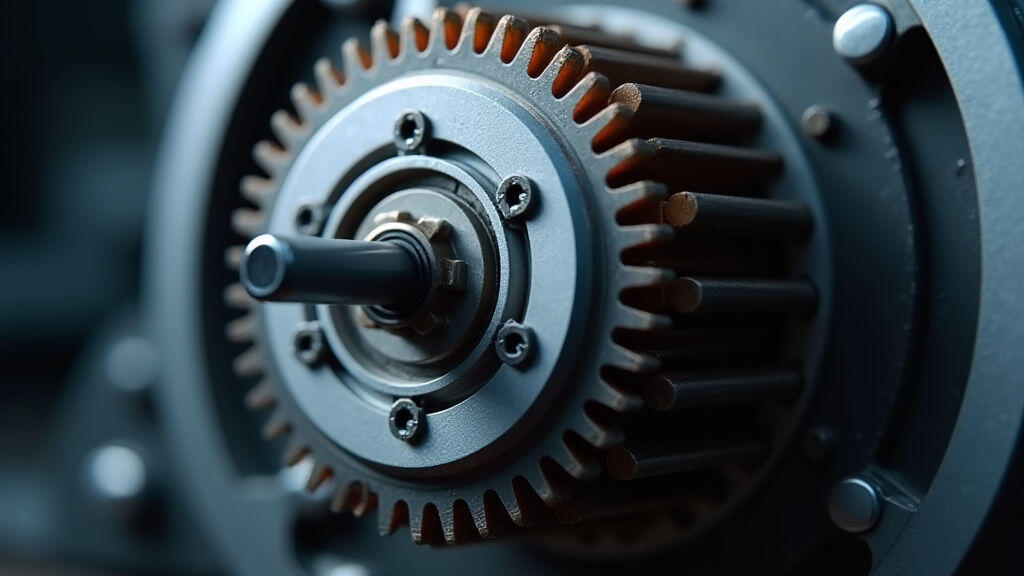

Essential for logistics and conveying automation upgrades: A guide to gear motor selection calculation and matching

The global logistics and warehousing industry is undergoing a rapid transformation, driven by e-commerce boom, increasing demand for faster delivery, and the relentless pursuit of efficiency. Automation is no longer a futuristic concept; it’s a critical necessity for businesses to remain competitive. And at the heart of most automated logistics systems lies the humble, yet vital, gear motor. Selecting the right gear motor isn’t just about finding a component; it's about ensuring the smooth, reliable, and cost-effective operation of entire automated processes. This guide will delve into the crucial aspects of gear motor selection, calculation, and matching for effective logistics and conveying automation upgrades.

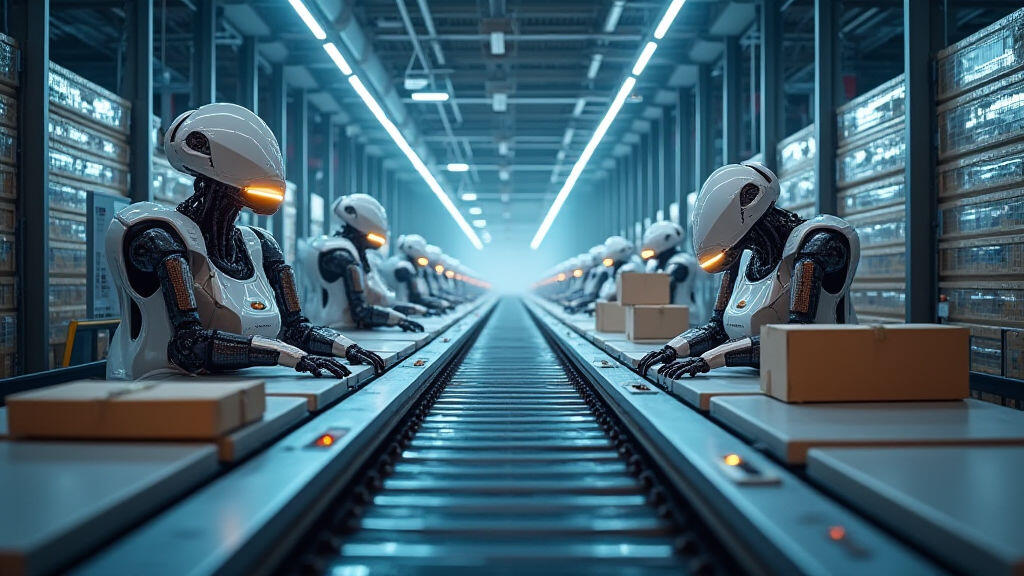

The Rise of Automation in Logistics: Why Gear Motors Matter

Consider the sheer scale of modern warehouses and distribution centers. Robotic guided vehicles (AGVs) navigating aisles, automated sorting systems, conveyor belts moving goods, and automated guided robots (AGVs) – all rely on motors to power their movements. This automation revolution is being amplified by advancements in artificial intelligence (AI) and machine learning (ML), enabling more sophisticated and adaptive systems. AI algorithms optimize routes, predict maintenance needs, and improve overall system performance. However, even the smartest AI needs reliable, efficient motors to execute its plans.

Gear motors are instrumental in achieving this automation. They provide a critical combination of torque and speed, crucial for driving heavy loads, precise movements, and maintaining system stability. The efficiency of the gear motor directly impacts energy consumption, operational costs, and the overall lifespan of the automated system. Choosing the wrong gear motor can lead to system downtime, costly repairs, and hindered performance.

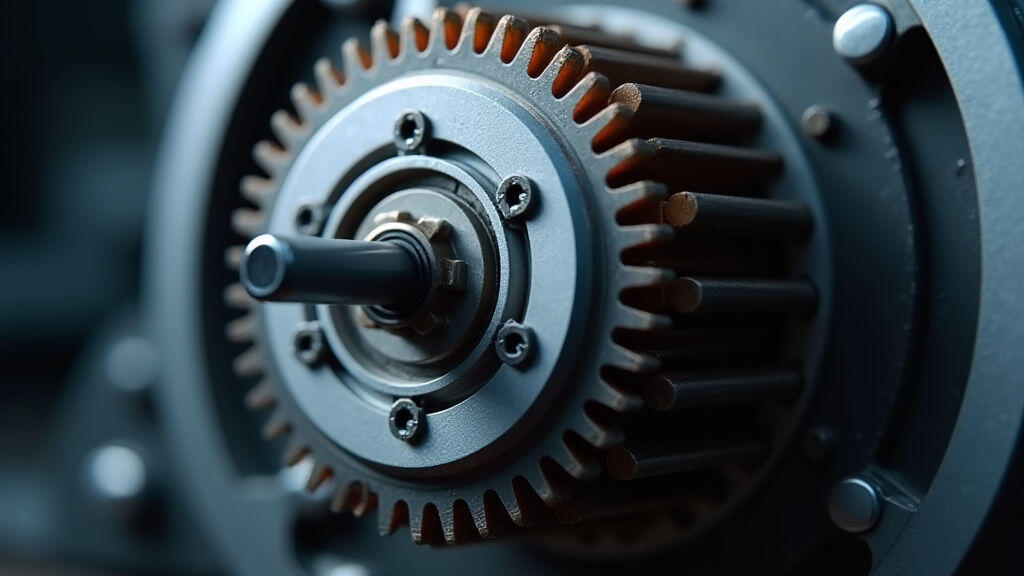

Understanding Key Gear Motor Specifications

Before diving into calculations, it’s vital to understand the core specifications that define a gear motor’s capabilities:

- Torque: The rotational force the motor can exert. Measured in Newton-meters (Nm) or pound-feet (lb-ft). This is arguably the most critical parameter for conveyor systems – it determines the motor’s ability to overcome friction, gravity, and the weight of the load.

- Speed: The rotational speed of the motor, typically measured in revolutions per minute (RPM). The required speed depends on the application – slower speeds for heavy lifting and faster speeds for high-throughput sorting.

- Gear Ratio: The ratio of input speed to output speed, determined by the gear system’s design. Higher gear ratios provide higher torque but lower speed.

- Power: The rate at which work is done. Often expressed in Watts or horsepower (hp). Power is directly related to torque and speed. (Power = Torque x Speed).

- Efficiency: The ratio of output power to input power, expressed as a percentage. Higher efficiency translates to lower energy consumption and operating costs.

- Motor Type: Different motor types (DC, AC, stepper, servo) offer varying performance characteristics. The choice depends on the application's requirements for accuracy, speed control, and power. Servo motors, for instance, are favored when precise position control is essential.

- Gearbox Type: Various gearbox designs (planetary, bevel, worm) each offering different advantages – compact size, high torque capacity, or smooth operation.

The Gear Motor Selection Calculation Process: A Step-by-Step Guide

Selecting the right gear motor involves a systematic calculation process. Here’s a breakdown:

1. Determine Load Requirements:

- Weight of the Load: This is the fundamental starting point. Accurate weight estimation is crucial.

- Friction: Account for friction in the system (bearings, belts, rollers). A conservative estimate is always advisable.

- Inclination/Gravity: If the conveyor is inclined, factor in the component of gravity acting on the load.

- Acceleration/Deceleration: How quickly does the system need to accelerate and decelerate? This impacts torque needs.

2. Calculate Required Torque:

- Torque (Nm) = (Load Weight (kg) x Gravity (9.81 m/s²) x Distance to Center of Rotation (m)) + Friction Torque.

- Ensure consistent units throughout the calculation.

3. Select a Motor Speed:

- Base the speed on the required conveyor throughput and the speed of other components in the system. Consider the optimal speed range for the chosen gear motor type.

4. Calculate Required Gear Ratio:

- Gear Ratio = Motor Speed / Required Conveyor Speed

- Select a standard gear ratio that’s available from motor manufacturers.

5. Determine Required Motor Power:

- Power (Watts) = (Torque (Nm) x Speed (RPM)) / 9.549 (converting Nm to lb-ft)

6. Efficiency Considerations:

- Account for the efficiency of the gear motor. A lower efficiency means the motor needs to be more powerful to deliver the same output.

MES-Drive offers a comprehensive suite of gear motor selection tools and expert consultation to streamline this process. Our online calculator simplifies these calculations and provides recommendations based on your specific needs.

Matching the Gear Motor to the Application

The calculations provide a starting point, but successful matching requires considering additional factors:

- Environmental Conditions: Temperature, humidity, and dust levels can affect motor performance and lifespan. Select motors rated for the specific environment. In dusty environments, sealed gear motors with protective covers are essential.

- Duty Cycle: Continuous operation, intermittent operation, or variable loads – all impact motor selection.

- Space Constraints: Available space in the system can limit the size and configuration of the gear motor.

- Maintenance Requirements: Consider the ease of access for maintenance and the availability of spare parts.

- Integration with Control Systems: Ensure the gear motor is compatible with existing or planned control systems.

The Future: AI-Powered Motor Optimization

The application of AI and ML is extending beyond system automation. Manufacturers like MES-Drive are integrating AI into motor design and selection processes. This includes:

- Predictive Maintenance: AI algorithms analyze motor performance data to predict potential failures and schedule maintenance proactively.

- Optimized Gear Ratio Selection: AI can optimize gear ratio selection based on real-time load conditions and system performance, improving efficiency.

- Adaptive Motor Control: AI-powered motor controllers can dynamically adjust motor parameters to optimize performance under varying load conditions.

Conclusion: Gear Motors – The Unsung Heroes of Automation

Selecting the right gear motor is a cornerstone of successful logistics and conveying automation upgrades. By understanding the key specifications, employing a calculated selection process, and considering application-specific factors, businesses can ensure reliable and efficient operation. With the increasing adoption of AI and ML in logistics, the role of these motors is becoming even more crucial.

The current global supply chain disruptions highlight the volatility of the industry. Robust, reliable automation systems are paramount to overcoming these challenges. MES-Drive is committed to providing high-quality gear motors and expert support to empower businesses to build resilient, efficient, and intelligent logistics solutions. As AI continues to revolutionize the industry, gear motor technology will evolve alongside it, enabling even greater levels of automation and optimization.

Leave A Reply

Your email address will not be published. Required fiels are marked