Introduction

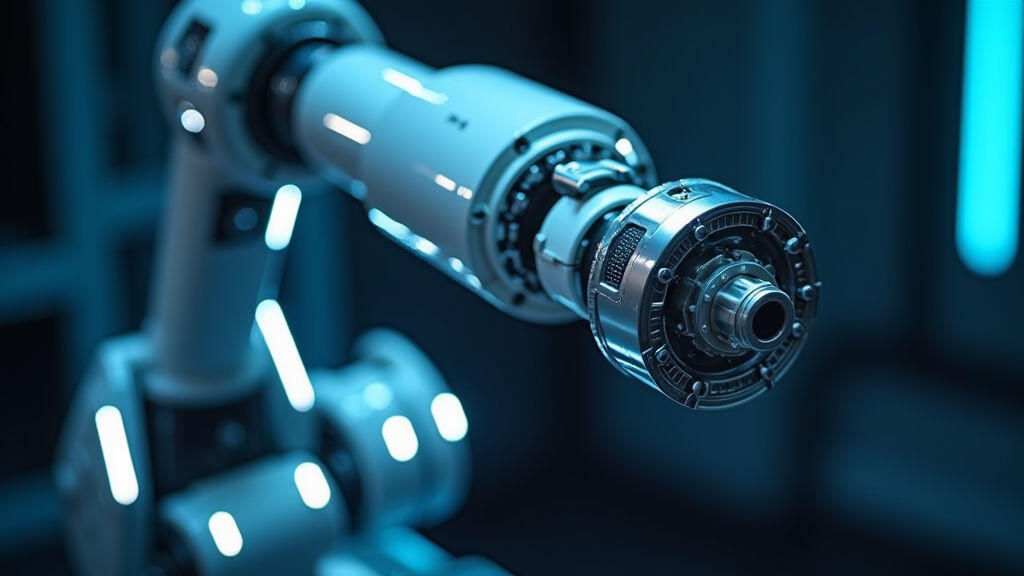

Robotics automation is moving fast, especially in small‑batch production and flexible manufacturing plants. A reliable automation upgrade often hinges on one seemingly simple component: the right‑angle gear motor. These compact engines deliver torque where the working space is limited, making them indispensable for robots that need to turn or pivot without a large footprint. This guide walks you through the basics of selecting and matching a right‑angle gear motor to your robot’s needs, so you can boost performance without losing precision.

Why Right‑Angle Gear Motors Matter

Because of these traits, right‑angle motors often become the backbone of modern pick‑and‑place robots, gantry systems, and collaborative arms.

Key Selection Criteria

When upgrading or building a new robotic system, start with a clear list of your mechanical and operational demands.

| Parameter | Why it matters | How to decide | |-----------|----------------|----------------| | Torque (Nm) | Guarantees the motor can drive the load without stalling | Calculate the moment of inertia and required drive speed for each joint; add a safety factor of 1.5–2×. | | Speed (RPM) | Controls the movement speed of the robot | Match the desired linear/spherical speed with the gear ratio. | | Power (W) | Must support the product of torque and speed; governs heat and battery life | Use P = τ × ω (τ=torque, ω=angular speed). | | Size (diameter × length) | Must fit within the rack or cabinet | Measure the available shaft clearance and enclosure constraints. | | Mounting and Shaft Type | Affects coupling options and durability | Prefer standard 5–mechanical or 5‑plain, or choose a custom fit if you need a tighter clearance. | | Environmental Tolerances | Determines protection level against dust, moisture and vibration | Choose NEMA 4/4X for damp environments, or IP65 for harsh conditions. | | Control Interface | Simplifies integration with existing PLC or motion controller | Halogen, PWM, or servo‑style DC input; correspond to your PCB or driver board. |

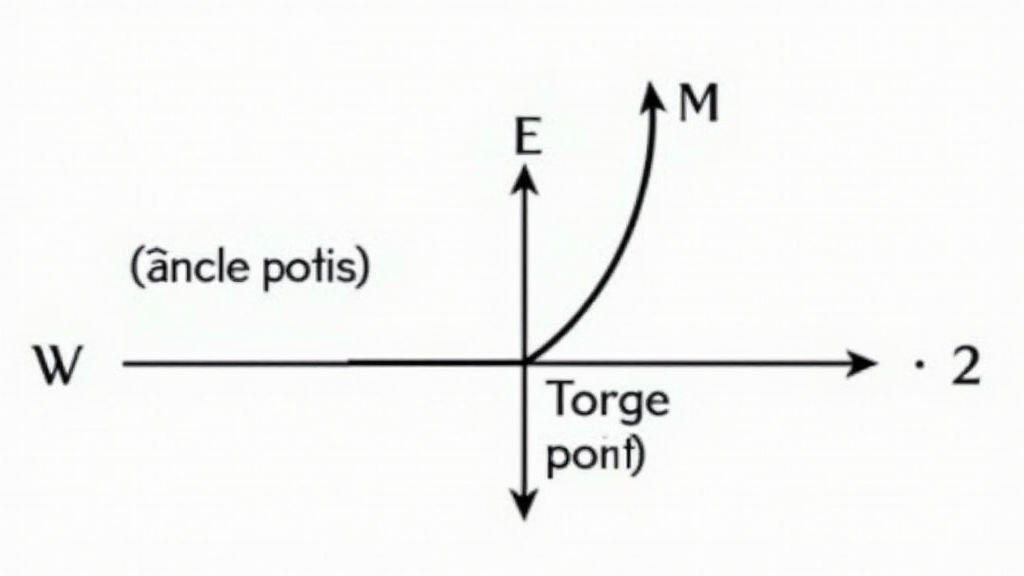

Matching Motor & Gear Sizes

Right‑angle gear motors usually combine a motor body with an internal gear train (planetary, helical, or spur).

After this exercise, you’ll have a rough motor‑gear pair. Refine your selection with a quick simulation or a bench test.

Integration Tips

Case Study: Upgrade on a Pick‑and‑Place Robot

A mid‑size electronics plant replaced its aging brushed DC motors with right‑angle gear motors in a 10‑down chain. The new drives offered 20% higher torque, doubled payload, and a 30% reduction in maintenance downtime. By coordinating the gear ratios with the robot’s speed profile, the operators achieved a cleaner edge seal on all printed circuit boards, enhancing product quality.

Conclusion

Right‑angle gear motors carry the promise of higher reliability, tighter packaging, and increased force handling for robotics automation upgrades. Selecting the right pair is more than looking up a datasheet—it involves a clear understanding of torque, speed, size, and environmental demands, followed by thoughtful matching on the motor‑gear interface. When these elements align, the result is a robot that moves faster, turns sharper, and works cleaner, paving the way for more flexible and cost‑effective production lines.

As the industry shifts toward higher‑resolution, multi‑axis robots, the importance of a well‑chosen right‑angle gear motor will only grow. Future trends, such as additive‑manufactured gear housings and integrated sensor suites, promise even greater customization and performance. By mastering the fundamentals today, you’ll set the stage for tomorrow’s next‑generation automation.

Leave A Reply

Your email address will not be published. Required fiels are marked