In the fast‑moving world of industrial automation, small is often spectacular. Micro DC gear motors are the heart of miniature robotic actuators, providing the precise motion and reliable power needed for everything from packaging lines to collaborative robots that share workspaces with humans. Choosing the right motor isn’t just a technical decision – it’s a strategic one that can make or break a production upgrade. This guide breaks down the key factors in selecting and matching micro DC gear motors, and shows why mastering this process is essential for anyone looking to stay ahead of the automation curve.

Automation no longer hinges solely on large, heavy equipment. The rise of Industry 4.0, IoT, and AI-driven manufacturing has made compact, high‑performance motors a priority. Micro DC gear motors are preferred because:

When a plant upgrades its pick‑and‑place line or adds collaborative arms to a line, the micro DC gear motor choice can significantly influence reliability, cycle time, and maintenance costs.

Below is a practical step‑by‑step framework for evaluating and matching motors. Think of it as a “menu” where you pick the right ingredients to craft a perfect robot component.

The amount of force a motor can deliver is a baseline metric. Start with the maximum load your robotic joint will lift or move. Add a safety factor (usually 1.4 to 1.5 in most factories) to cushion spikes. For example, if your gripper must lift 0.5 kg, the motor should comfortably handle at least 0.7 kg·m at the shaft.

Micro gear motors often trade speed for torque. Use the motor’s constant‑torque speed (typically at no load) as a reference. Higher gear ratios give more torque but lower speed. Ensure the chosen motor meets the required joint velocity – a 500 RPM motor may suffice for a slow conveyor, but a 2000 RPM motor might be needed for a rapid pick‑and‑place cycle.

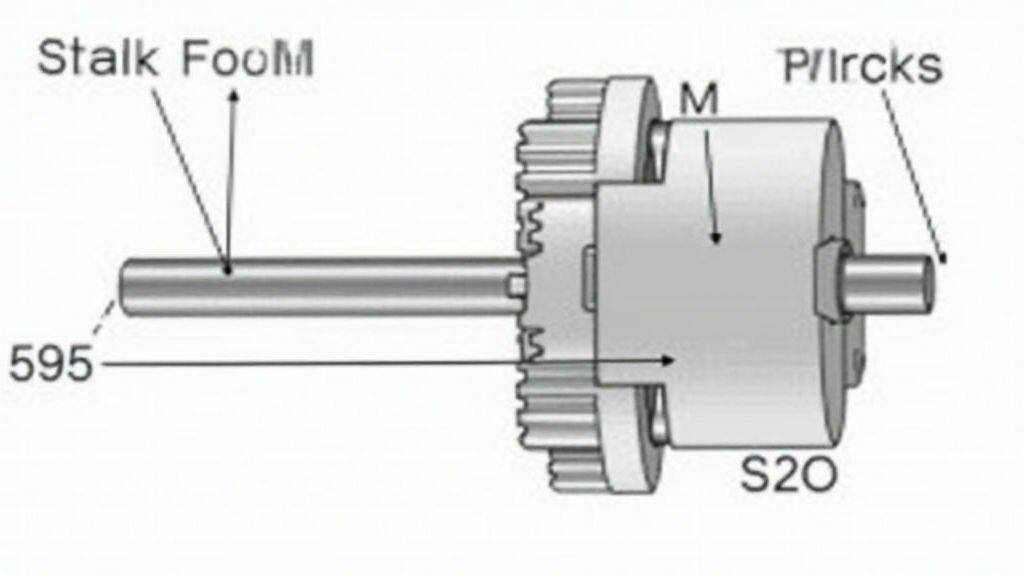

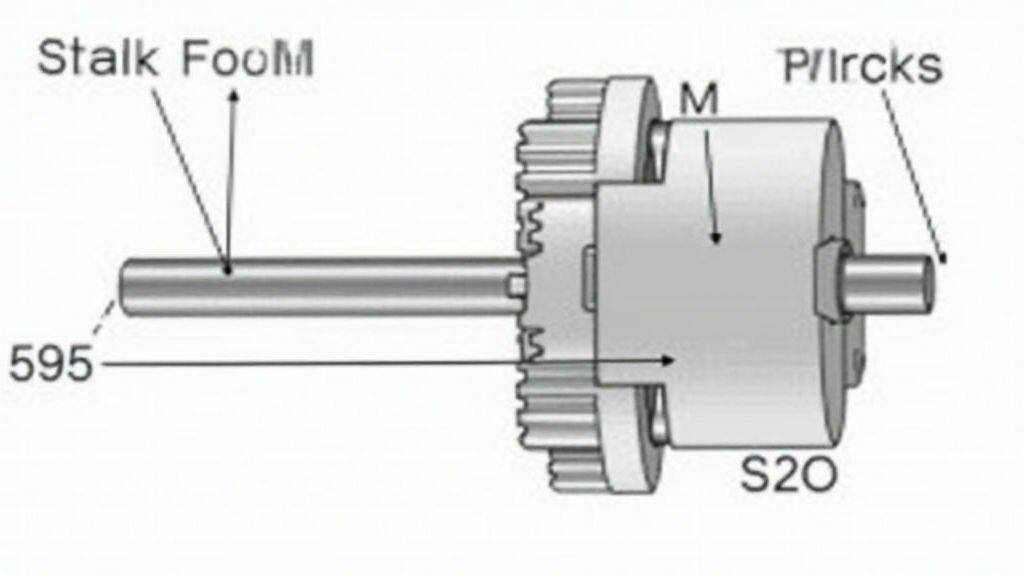

The gear ratio determines the scale of torque multiplication. Avoid designs with extreme ratios unless absolute high torque is required, as backlash – the small gap between teeth – can reduce positioning accuracy. Choose a moderate ratio (10:1–30:1) for most precision robots, and consider planetary or harmonic gearboxes for tight accuracy demands.

Match the motor’s rated voltage to your power supply. Use a driver or motor controller that can handle the current draw, typically up to 1.2–1.5 times the nominal current to account for load spikes. Micro controllers often use PWM for speed modulation; ensure your controller’s logic levels align with the motor’s input requirements.

The shaft size should match your mechanical coupling. Common diameters are 2 mm, 3 mm, and 4 mm for micro motors. If your robot uses a standard 3 mm shaft, stick with a 3 mm motor, or use a shaft adapter.

Consider the operating environment. A motor rated IP66 or IP67 provides dustproofing and water resistance – essential for food‑processing or outdoor-use robots. Temperature ratings (e.g., 70 °C continuous or 100 °C intermittent) dictate where the motor can safely operate without overheating. In cleanrooms, pick a motor with a low-particulate rating.

Micro DC gear motors with high gear tooth quality, proper lubrication, and preassembled gearboxes usually exceed 10,000 h of continuous operation. For mission‑critical applications, evaluate mean‑time‑between‑failure (MTBF) statistics or ask for warranty‑based specifications.

Use drawer, plastic, or metal housings based on your design. Drawer mounting simplifies axis alignment in robotic arms, while integrated housings reduce assembly steps. Pay attention to overall motor thickness if cage space is limited.

After you’ve assessed the above parameters, the real match begins. Below is a miniature workflow:

Iterative prototyping is essential because real-world loads often differ from theoretical calculations. Unexpected backlash or spare torque can disclose latent issues early, saving costly redesigns later.

Consider a small electronics manufacturer upgrading its six‑degree‑of‑freedom robotic arm. The main constraints were high speed for rapid soldering and the need for a minimal footprint. The design team selected a 12:1 gear ratio motor rated at 200 RPM and maximum torque 0.25 kg·m. By pairing this motor with a lightweight aluminum frame and a micro‑controller-based PWM driver, the cycle time dropped from 4 s to 2.5 s, while maintenance costs fell due to the motor’s high MTBF of 15,000 h.

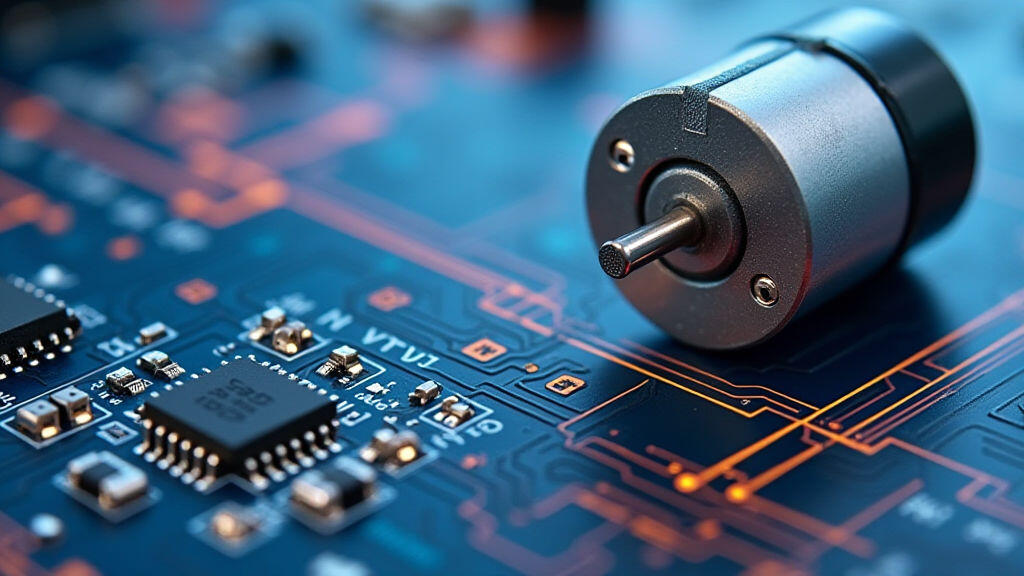

Smart factories are leveraging AI to predict motor wear and schedule maintenance. Sensors embedded in micro DC gear motors can now report temperature, vibration, and current draw in real time. By feeding these data into an AI model, operators avoid unexpected downtime and extend motor life. This shift from reactive to predictive is redefining how micro motors are chosen: reliability metrics become as important as torque and speed.

Micro DC gear motors are the unsung heroes of modern robotic automation. By carefully evaluating torque, speed, gear ratio, electrical compatibility, environmental ratings, and lifetime specifications, engineers can choose motors that not only meet but exceed project goals. In an era where speed, miniaturization, and reliability dictate competitive advantage, mastering motor selection is not just a technical requirement – it’s a strategic necessity. As AI predictive maintenance continues to mature, the margin between a reliable system and a costly failure will hinge on the precision of your motor choices. Invest in thoughtful selection now, and you'll build a robot that stays agile, efficient, and ready for whatever tomorrow brings.

Leave A Reply

Your email address will not be published. Required fiels are marked