In today's fast-paced world of logistics and manufacturing, efficiency is paramount. Production lines are constantly striving to optimize speed, minimize downtime, and reduce energy consumption. A critical component driving these advancements is the motor, the workhorse that powers everything from conveyor belts to automated sorting systems. Within the realm of motors, a key distinction lies between standard motors and gear motors. Understanding their differences is crucial for businesses looking to enhance operational performance and achieve significant cost savings. This article delves into the intricacies of gear motors and regular motors, highlighting their advantages, disadvantages, and how choosing the right one can revolutionize logistics and conveying production lines. We'll also touch upon the growing importance of sustainable practices, a key trend influencing motor technology choices.

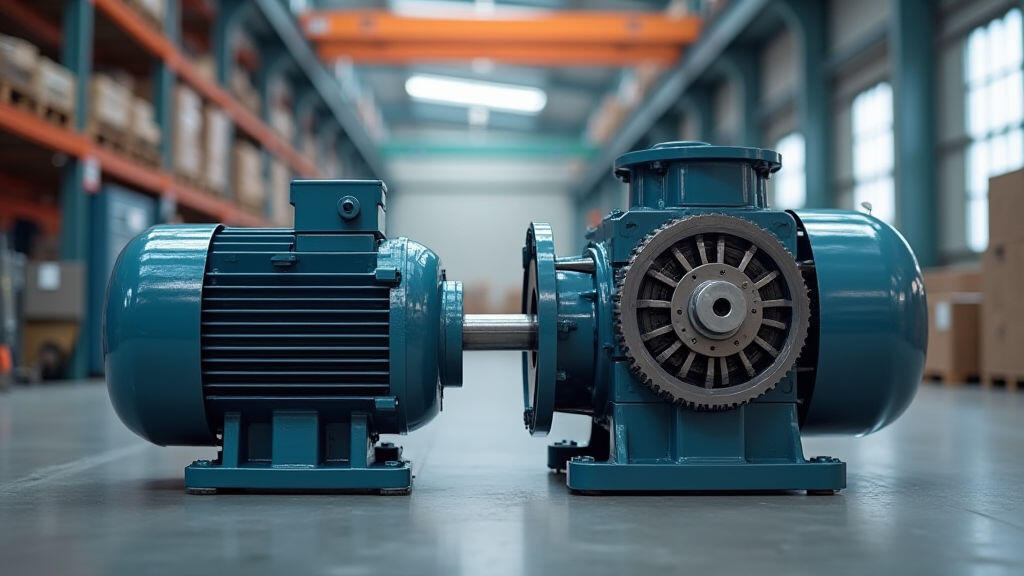

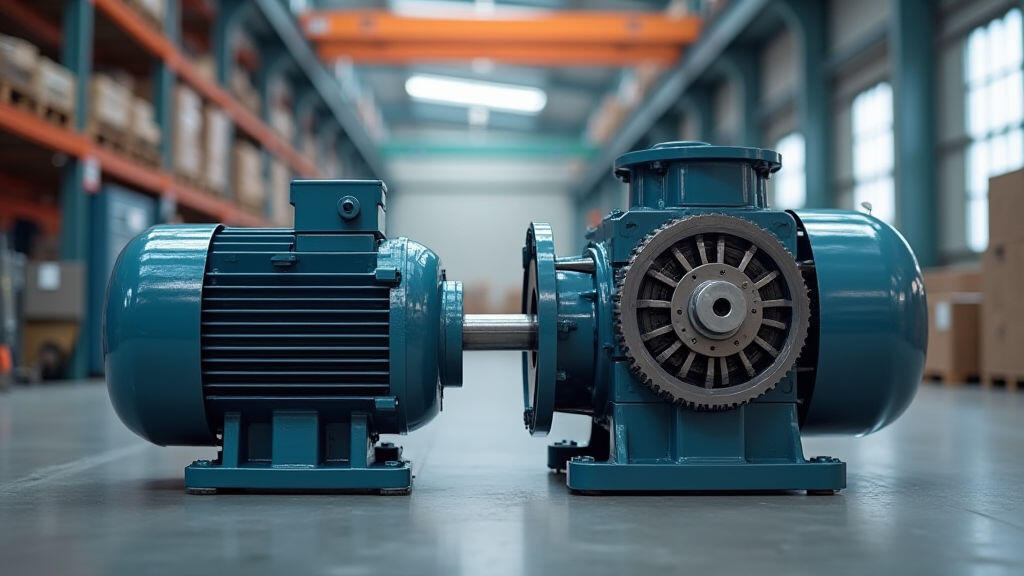

A regular motor, also known as a direct-drive motor, converts electrical energy into rotational motion. It operates at a specific speed determined by the electrical frequency and the number of poles in the motor’s windings. Common types include AC induction motors, DC motors, and stepper motors. These motors are generally robust and efficient for applications requiring relatively low speeds and high torque.

A gear motor, on the other hand, combines a motor with a gearbox. This gearbox reduces the motor's output speed while simultaneously increasing its torque. The reduction in speed is achieved through a series of gears that mesh together. This allows gear motors to deliver significantly higher torque at lower speeds than a direct-drive motor of similar size and power. This is the core advantage that makes them indispensable in many logistical applications.

Here's a detailed comparison of regular motors and gear motors across several important parameters:

| Feature | Regular Motor | Gear Motor | |-------------------|--------------------------------------|---------------------------------------| | Speed | High (determined by frequency) | Low (reduced by gearbox) | | Torque | Relatively low | High (increased by gearbox) | | Efficiency | Generally excellent at its rated speed | Can be slightly lower due to gear losses | | Size & Weight | Typically smaller for equivalent HP | Larger and heavier for equivalent HP | | Cost | Generally lower | Higher | | Maintenance | Generally lower | Can be higher due to gear wear | | Applications | Applications requiring high speed, low torque | Applications requiring low speed, high torque |

The choice between a regular motor and a gear motor significantly impacts the performance and capabilities of logistics and conveying systems. Let's explore some common applications:

Conveyor Systems: Gear motors are the preferred choice for driving conveyor belts, especially those needing to handle heavy loads or operate at varying speeds. The high torque enables the system to start and stop quickly, even when fully loaded. Consider a large automated warehouse. Gear motors power the incline conveyors that move goods to higher storage levels. Without the increased torque, starting and stopping such conveyors would be challenging, leading to delays and potential equipment failure. MES-Drive offers a range of gear motors specifically designed for the demanding requirements of conveyor applications, ensuring smooth, reliable operation.

Automated Sorting Systems: These systems require precise control and the ability to handle diverse package sizes. Gear motors, often coupled with sophisticated control systems, provide the necessary torque and accuracy to reliably sort items based on weight, size, or destination. The ability to precisely control the speed and torque of each sorting mechanism is crucial for minimizing errors and maximizing throughput.

Robotics and Automated Guided Vehicles (AGVs): Robots and AGVs rely on powerful and precise motor control. Gear motors enable these systems to maneuver heavy payloads and execute intricate tasks with accuracy. The high torque allows for efficient acceleration and deceleration, while the reduced speed provides greater control over movements.

Packaging Machinery: Many packaging machines, from filling equipment to sealing mechanisms, utilize gear motors to drive the various components. The high torque is essential for handling heavy materials and performing precise operations.

In an era of increasing environmental awareness and stringent energy regulations, energy efficiency is a critical consideration in motor selection. While gear reduction inherently introduces some energy losses due to friction within the gearbox, modern gear motor designs are constantly improving to minimize these losses.

Furthermore, advanced motor control technologies are playing a vital role in boosting energy efficiency. Variable Frequency Drives (VFDs) allow for precise control of motor speed, matching motor output to the actual load requirements. This eliminates unnecessary energy consumption associated with running motors at full speed when they are not required. MES-Drive’s VFD-compatible gear motors offer significant energy savings and contribute to a reduced carbon footprint.

The concept of the Industrial Internet of Things (IIoT) is also transforming motor management. Smart motors and sensors provide real-time data on motor performance, allowing for predictive maintenance and optimized operation, further enhancing energy efficiency and reducing downtime.

The future of motor technology is undeniably linked to sustainability and intelligence.

Eco-friendly materials: Manufacturers are increasingly using eco-friendly materials in motor construction, reducing the environmental impact.

Improved gearbox designs: Research is focusing on reducing friction and optimizing gear geometry to minimize energy losses and extend gearbox lifespan.

AI-powered predictive maintenance: Artificial intelligence is being used to analyze motor data and predict potential failures before they occur, preventing costly downtime and maximizing equipment lifespan.

Integration with renewable energy sources: Motors are being designed to seamlessly integrate with renewable energy sources like solar and wind power, creating more sustainable production systems.

Choosing between a regular motor and a gear motor hinges on the specific requirements of the application. Gear motors excel in scenarios demanding high torque at low speeds, making them ideal for logistics and conveying systems. By understanding the key differences, carefully evaluating application needs, and adopting advanced motor control technologies, businesses can significantly enhance operational efficiency, reduce energy consumption, and boost overall productivity. With the growing emphasis on sustainable practices and the advent of smart motor solutions, the future of motor technology promises even greater efficiency, reliability, and environmental responsibility. In the context of the current global focus on supply chain resilience and sustainable manufacturing, optimizing logistics and conveying systems with the right motor technology is no longer just an advantage – it’s a necessity for long-term success. MES-Drive is dedicated to providing innovative and efficient motor solutions that empower businesses to achieve their operational and sustainability goals.

Leave A Reply

Your email address will not be published. Required fiels are marked