Introduction

Gear motors—integrated devices that combine an electric motor with a gear train—play a pivotal role in modern manufacturing. From high‑speed PCB assembly lines to precision CNC machining, they convert electric energy into controlled mechanical motion, offering a compact solution that delivers high torque, low speed, or precise positioning. Although the underlying principle is simple, the diversity of gear types, power ratings, and applications can make selection challenging. This article provides an in‑depth look at how gear motors work, the key performance metrics that distinguish them, and why they remain essential as manufacturing turns increasingly toward automation and smart factories.

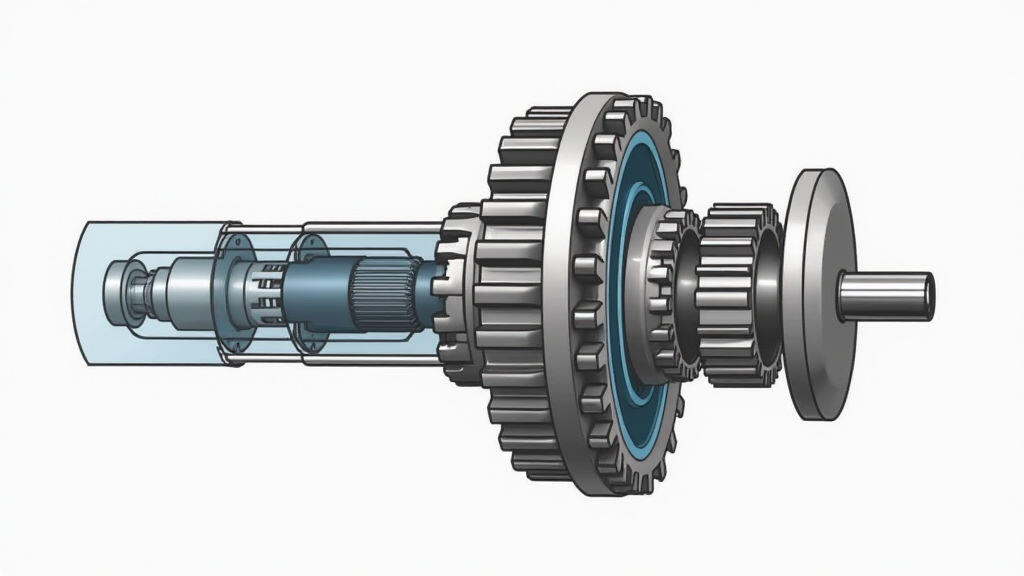

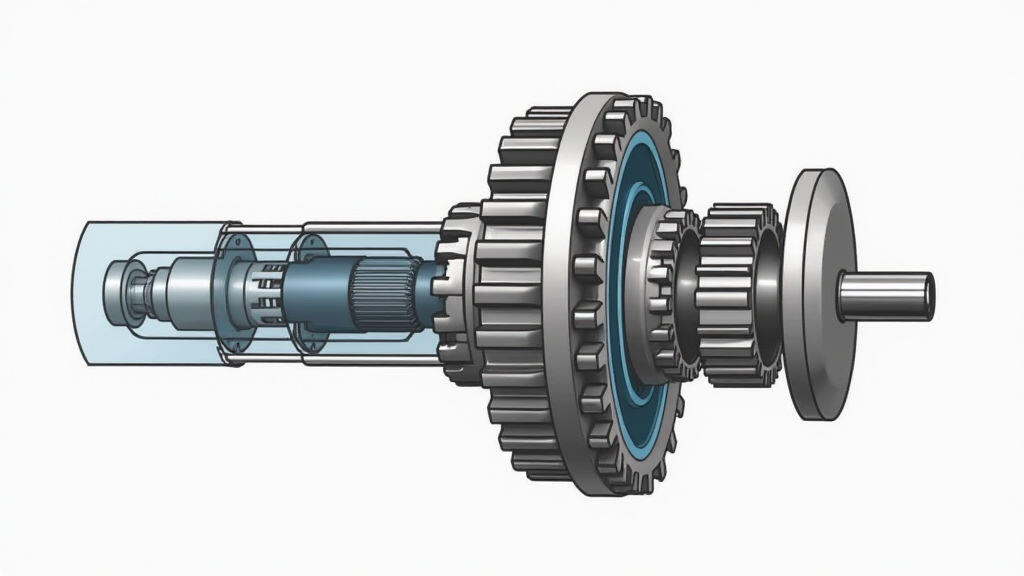

1. How Gear Motors Work

At its core, a gear motor is a conventional electric motor whose shaft is attached to a gear train. The motor’s shaft rotates, turning the gears that either increase torque and decrease speed (gear reduction) or the opposite (gear increase). The gear train can be a single gear pair or a complex arrangement of multiple gears to tailor the torque‑speed curve for a specific task.

The motor itself can be AC or DC. AC gear motors, such as induction or synchronous types, are robust and ideal for continuous operation. DC gear motors—shunt, series, or brushless—offer finer speed control, higher torque at low speed, and are preferred in applications where precise positioning is critical.

2. Types of Gearing in Motor Design

| Gear Type | Key Feature | Typical Use in Manufacturing | Example Application |

|-----------|-------------|------------------------------|---------------------|

| Spur Gear | Simple, high-speed, low torque | High‑speed conveyors, belt drives | Power transmission in fast-moving assembly line |

| Planetary Gear | Compact, high torque density, smooth | CNC machine spindles, robotic wrists | 3‑axis milling centers |

| Worm Gear | High reduction ratio, self‑locking | Automated vertical lifts, CNC gantry | Height‑adjustable workstations |

Each gear type offers a trade‑off between size, efficiency, torque, noise, and load capacity. Selecting the right geometry can reduce motor size and cost while meeting performance targets.

3. Performance Parameters: What Matters Most

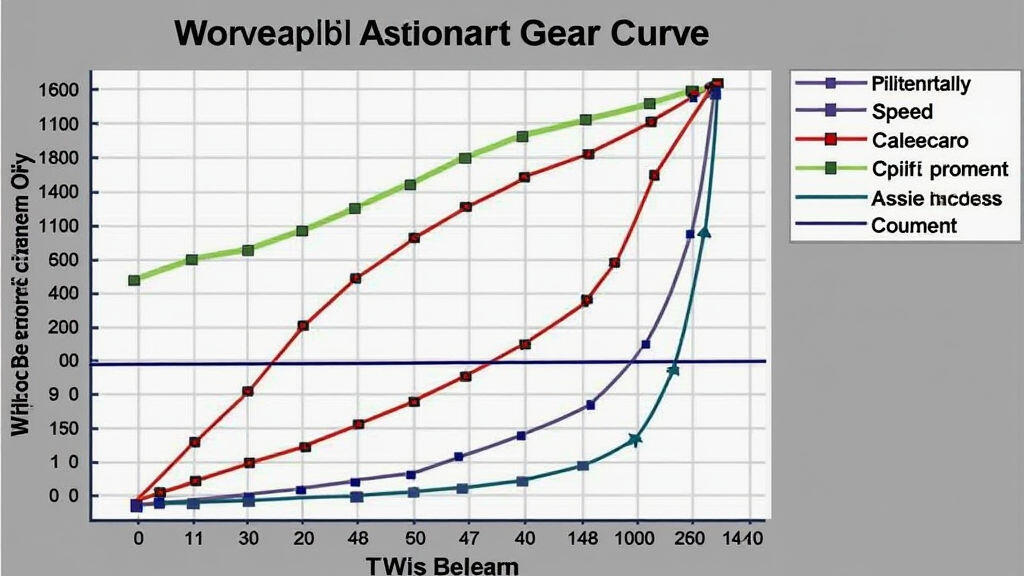

When choosing a gear motor, engineers look at four primary metrics:

In practice, these metrics are interdependent. Increasing torque often means reduced speed and higher heat; higher precision often requires additional sensors or feedback. Therefore, a holistic trade‑off analysis is necessary.

4. Performance Comparison Across Gear Motor Series

Consider two widely used gear motor families: the Fanuc M‐series (planetary, high torque, <90 % efficiency) and the Siemens 3XL (spur gear, medium torque, >95 % efficiency).

Choosing between these motors boils down to the application’s torque demands versus speed and energy budgets.

5. Real‑World Applications in Manufacturing

| Application | Gear Motor Choice | Why It Works | Performance Highlights |

|-------------|------------------|--------------|------------------------|

| Automated Pick‑and‑Place | Brushless DC planetary | Compact, high precision | 200 µs response time |

| CNC Spindle | Induction planetary | High torque, temperature‑resistant | 500 Nm torque, 3600 RPM |

| Robotic Arm Wrist | Worm gear (closed‑loop) | Self‑locking, fine control | 50 Nm torque, sub‑0.2° accuracy |

| Vertical Lift Assembly | AC spur gear | High power, low maintenance | 3000 Nm, 80 % efficiency |

These examples illustrate that gear motors are not one‑size‑fits‑all. Instead, a careful match of gear type, motor topology, and control strategy yields optimal performance.

6. Trending Event: Industry 4.0 Integration

The latest trend in manufacturing—the digital thread—has emphasized data‑centric controls and predictive maintenance. Gear motors equipped with smart sensors can report temperature, vibration, and torque in real time. By feeding this data into an IoT platform, factories can anticipate failures, schedule maintenance, and reduce unplanned downtime by 20 %. Additionally, software‑defined motor profiles enable rapid re‑configuration of robots for multi‑tasking without physical re‑tooling.

7. Future Potential and Emerging Technologies

Advances in materials—such as high‑strength composites for gear teeth—promise to increase torque density while lowering weight. Heterogeneous gear trains that blend worm and planetary stages can offer both high reduction and high precision in a single compact unit. Moreover, combining gear motors with magnetic levitation bearings may eliminate friction losses, pushing efficiencies beyond 95 % even at high torque.

Conclusion

Gear motors remain the cornerstone of modern manufacturing because they translate electrical energy into precise mechanical motion in a compact, reliable package. By understanding the fundamentals—gear type, torque‑speed characteristics, and efficiency—and matching them to specific applications, engineers can design systems that are both powerful and energy‑efficient. As Industry 4.0 pushes for smarter, data‑driven production lines, the integration of smart gear motors will become even more critical, offering not only performance but also predictive insights that drive cost savings. In short, when the trend moves toward ever‑faster, more flexible factories, the gear motor—simple in principle but sophisticated in execution—will keep pace.

Leave A Reply

Your email address will not be published. Required fiels are marked