DC gear motors are the quiet workhorses of modern logistics and conveying systems. By combining the simplicity of a DC motor with the torque‑multiplying power of a gearbox, they deliver precise speed control, high reliability, and lower energy consumption—key factors for factories looking to reduce operating costs and meet tighter environmental targets. This article walks through why choosing the right DC gear motor matters, how to assess the main variables, and what future trends could further improve performance on the production line.

In a distribution center, conveyors move thousands of items per hour. Even a small lag in speed can bottleneck the entire flow, delaying shipments and eroding customer confidence. At the same time, energy costs frequently account for 15–25 % of a plant’s operating budget. DC gear motors, when correctly matched to the load, can deliver high torque at low speeds while keeping power draw low. This dual benefit translates into smoother operations and significant electricity savings.

| Parameter | Why It Matters | Practical Tips | |-----------|----------------|----------------| | Speed (RPM) | Sets how fast the conveyor belt turns. A mismatch can cause either sluggish movement or excess wear. | Use encoder data from the line to set the target RPM; calculate required motor speed before reduction. | | Torque (Nm) | Determines the motor’s ability to pull or push the load. Over‑torque wastes power; under‑torque leads to slips. | Perform a load‑characteristic test: measure required torque at peak load and choose a motor that exceeds this by ~20 %. | | Efficiency (%) | Directly influences energy consumption and operating temperature. Higher efficiency reduces heat buildup and replacement frequency. | Look for motors rated >90 % efficiency at the intended load point. | | Duty Cycle | Describes how long a motor can run continuously. Logistics lines often run 24/7. | Choose motors with a duty cycle matching the plant schedule (e.g., 80 % for continuous operation). | | Maintenance Needs | Unplanned downtime is costly. DC gear motors with sealed bearings and self‑lubricating gearboxes extend service intervals. | Opt for low‑maintenance products designed for industrial environments. | | Integration with VSD | Variable Speed Drives (VSDs) allow dynamic speed control, further saving power during start‑up and idle times. | Ensure the motor’s voltage and current ratings are compatible with the chosen VSD. |

Selecting the right motor involves balancing these parameters against the specific requirements of the line. Oversizing a motor for speed may be harmless but can unnecessarily increase cost; undersizing a motor for torque can lead to mechanical failure and frequent repairs.

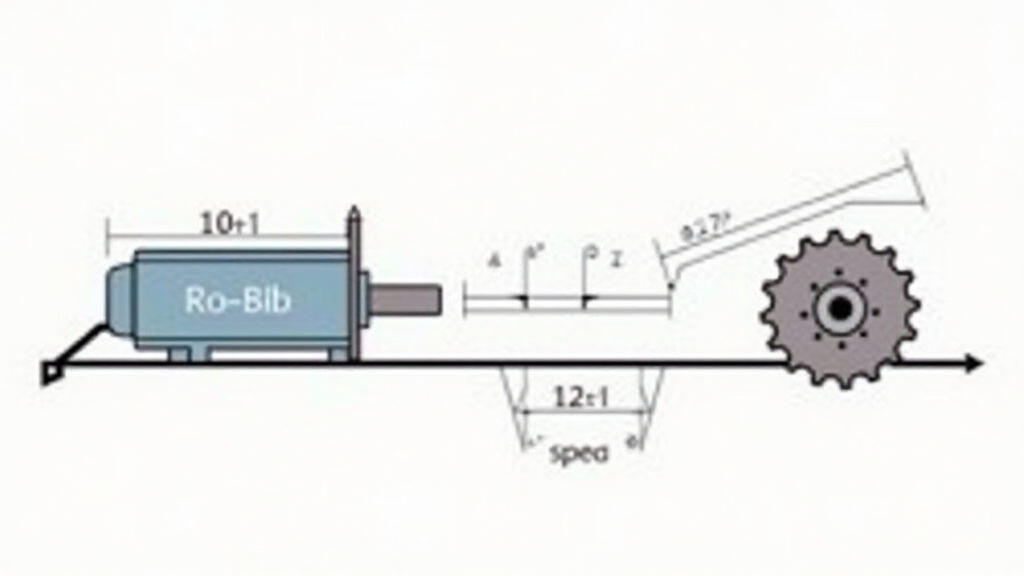

The relationship between motor speed, gearbox ratio, and belt speed is straightforward:

[ \text{Belt Speed (m/min)} = \frac{\pi \times \text{Belt Pitch} \times \text{Gear Ratio} \times \text{Motor RPM}}{60} ]

By rearranging this equation, engineers can determine the exact motor RPM required, taking gear ratio into account. A common practice is to use a gear ratio between 2:1 and 5:1, which keeps motor RPM within a safe operating window while providing the needed torque.

When a line includes multiple sections with varying loads, modular motor‑gearbox units can be swapped to maintain optimal performance across the entire route. This modularity also facilitates future upgrades: adding a higher‑torque motor to a downstream segment without reconfiguring the whole system.

A poorly chosen gear ratio can double a motor’s electrical draw. For instance, suppose a conveyor requires a torque of 50 Nm. A gear motor rated at 30 Nm would struggle, causing a larger, less efficient motor to run near its limits. In contrast, a correctly sized motor rated at 60 Nm can operate comfortably at 70 % load, yielding about 20 % lower energy usage and reducing heat output.

Case study: A mid‑size electronics assembly plant swapped an out‑dated 350 W DC gear motor for a newer 400 W unit with a 1:3 gear reduction. The new setup achieved the same belt speed at lower motor RPM, resulting in a 12 % reduction in yearly electricity costs—roughly $15 k saved on a 3‑year project.

Modern DC gear motors pair seamlessly with VSDs. During start‑up, the motor can accelerate gradually, minimizing voltage spikes. When the conveyor is idle, the VSD can reduce speed to a low‑idle mode, cutting current draw to near zero. Many DC gear motor suppliers now offer integrated VSD controllers tailored for specific motor models, simplifying commissioning and reducing mismatch losses.

Logistics environments demand resilience. Sealed gearboxes shield against dust and debris, preventing gear wear. Some manufacturers incorporate self‑lubricating gear housings, eliminating the need for periodic greasing. Additionally, DC motors with regenerative braking can return excess energy to the grid or recirculate it within the plant—an emerging feature in high‑throughput facilities.

When planning maintenance, schedule regular visual checks and set up vibration monitoring. A sudden change in vibration patterns often signals bearing wear or gear misalignment—issues that cost more if left unaddressed.

Choosing the right DC gear motor is more than a technical specification exercise; it’s a strategic lever for boosting both speed and energy efficiency in logistics and conveying production lines. By carefully matching motor speed, torque, and efficiency to the conveyor’s load profile—and by integrating with VSDs and maintenance‑friendly gearboxes—plants can achieve smoother operations, lower operating costs, and a stronger sustainability record. As digitalisation and semiconductor advances keep pushing the envelope, the next generation of DC gear motors will offer even greater flexibility, power density, and smart energy features—ensuring the logistics hubs of tomorrow run faster, cleaner, and smarter than ever before.

Leave A Reply

Your email address will not be published. Required fiels are marked