Automotive technology is evolving at a blistering pace. From electric drivetrains to intelligent cabin systems, every new feature demands reliable, compact actuators that can deliver motion precisely and efficiently. Dense‑circuit (DC) gear motors have become the workhorse of this evolution, powering everything from power windows to adaptive suspensions. However, simply swapping in a motor isn’t enough; selecting the right DC gear motor and configuring it appropriately is crucial for performance, safety, and longevity. This article walks you through the most effective strategies for choosing and integrating DC gear motors into upgraded automotive equipment, with a focus on clear, practical guidance.

Why Upgrade with DC Gear Motors?

Traditional brushed DC motors have reached their limits in terms of speed, torque, and reliability. In contrast, modern brushless DC (BLDC) gear motors combine high torque density, low maintenance, and precise speed control – all within a smaller footprint that automotive designs desperately need. By upgrading to a DC gear motor, manufacturers can:

- Reduce power consumption and heat production.

- Introduce faster, smoother motion for user‑facing components.

- Improve wear resistance and extend component lifetime.

- Lower component count thanks to integrated gearing.

These benefits translate directly into a better driving experience and a competitive edge in the marketplace.

1. Define the Core Performance Requirements

Before plumbing the supply lines, clarify the essential specifications your application demands:

- Torque Profile – Peak and continuous torque required to move or hold the component (e.g., a seat recliner may need 5–10 Nm continuously, but peak torque could reach 15 Nm).

- Speed Range – Minimum and maximum angular velocity; electric windows, for example, typically need 30–60 rpm for comfortable operation.

- Voltage & Current Constraints – Vehicle electrics allow only limited current draw, especially for systems shared with the main powertrain.

- Physical Envelope – Size and mounting format must fit within existing parts or target redesign space.

Collecting these parameters upfront lets you narrow the motor options and avoid costly rework later.

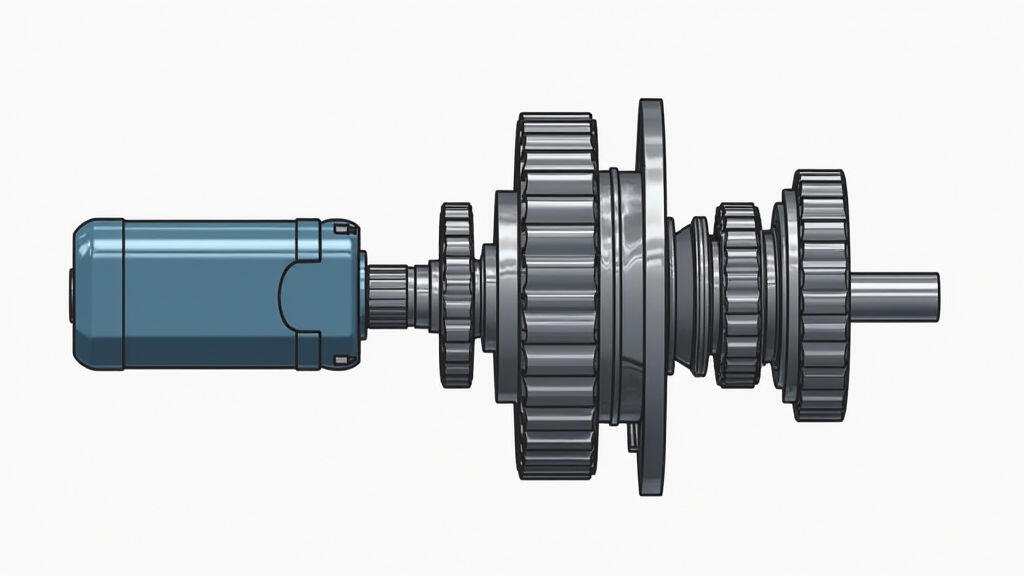

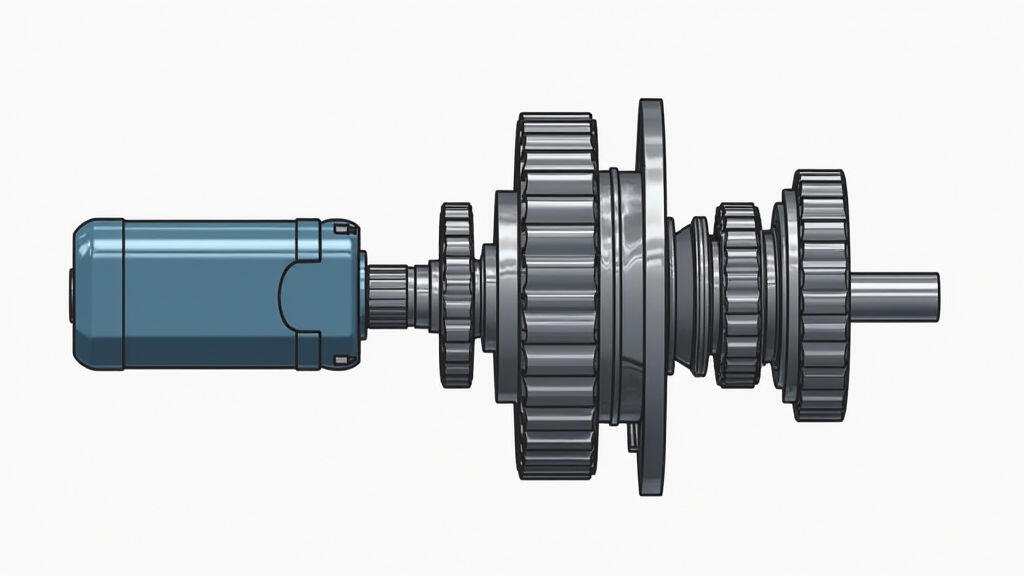

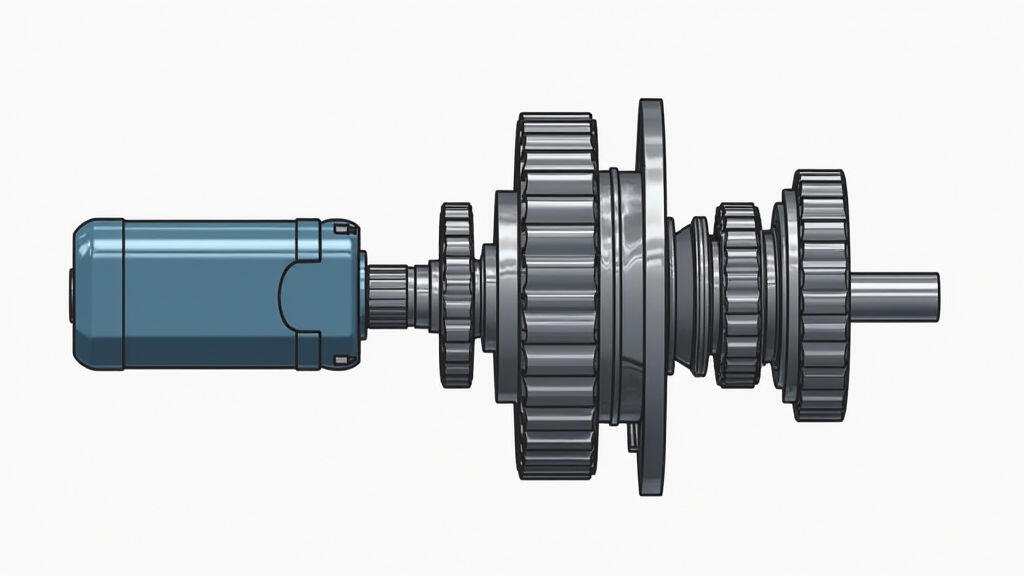

2. Select the Right Gear Ratio and Motor Type

Once you have the torque and speed targets, compute the required gear ratio. The gear ratio (output speed / input speed) is the bridge that scales a motor’s low torque, high RPM characteristics to the high torque, low RPM requirements of automotive components.

- **Choosing a Motor** – Brushless DC motors are preferred for their efficiency and reliability. Pick a motor that delivers the base torque while operating at a nominal speed comfortably above the required output speed.

- **Optimizing Gear Ratio** – A typical custom gearmotor may have ratios ranging from 20:1 to 60:1. Using the torque equation \(T_{\text{out}} = T_{\text{in}}\times G\) (where \(G\) is the gear ratio), adjust the ratio to meet the desired output torque without overstressing the motor.

- **Pulsation and Noise Control** – Higher gear ratios often increase noise. Counteract this by selecting gear geometries with smoother engagement (e.g., helical gears) or adding damping materials.

Balancing ratio, motor torque, and voltage requirements is the cornerstone of a robust design.

3. Configuring Thermal Management & Mounting

Heat is a hidden enemy in automotive applications, especially when motors run at high torques for extended periods. A well‑designed cooling strategy ensures longevity and prevents voltage drop.

- **Passive Cooling** – Many DC gear motors use finned housings that dissipate heat naturally. Position the motor near airflow channels or integrate it into the vehicle’s thermal path.

- **Active Cooling** – For high‑power installations (e.g., active suspensions), consider adding a small fan or heat sink directly on the motor case.

- **Mounting Points** – Use provisioned mounting brackets that align the motor’s shaft with the component’s drive mechanism. Keep the assembly rigid to minimise vibration transmission back to the vehicle chassis.

By coupling proper thermal handling with secure mounting, you guarantee that the motor stays within its operating envelope, avoiding unexpected failures.

4. Integrate Control Electronics Seamlessly

A motor alone is not enough; it needs a controller that can interpret vehicle signals and translate them into precise motion.

- **Speed & Torque Feedback** – Use sensors such as hall-effect encoders or motor driver interfaces that provide real‑time speed data to the vehicle’s ECU.

- **Closed‑Loop Control** – Implement PID algorithms in the vehicle’s controller to keep the motor performance consistent across temperature changes and load variations.

- **Safety Features** – Include over‑current protection, torque limiting, and fault detection (e.g., stalled motor detection) to protect the automotive system.

- **Compatibility** – Align the motor’s power electronics with the vehicle’s CAN or LIN bus. Many suppliers offer firmware that plugs directly into standard automotive modules.

Holistic integration ensures that the motor’s upgraded performance translates into a user‑awesome experience without compromising safety.

5. Walk Through an Upgrading Scenario: Power Window Actuator

Let’s apply these concepts to a tangible example – upgrading a traditional solenoid‑driven window to a smoother, faster DC gear motor.

- Performance Goals – Increase speed from 20 rpm to 45 rpm; improve torque from 2 Nm to 4 Nm to handle heavier aftermarket glass.

- Motor Selection – Pick a BLDC motor rated 1.2 Nm at 100 rpm with an integrated 30:1 gear reduction, giving 36 Nm output at 3.3 rpm. This meets the torque requirement; speed is increased by adding a gear up‑shift mechanism on the window regulator.

- Thermal & Mounting – Mount the motor on the side rail of the door, using the existing actuator flange. Add a small plastic cooler heated by the door’s airflow.

- Control Integration – Wire the motor driver to the vehicle’s power window ECU via CAN. Implement a torque limiter so that if the glass hits a stop, the motor automatically disengages to avoid damage.

- Testing – Run cycles across temperature extremes (–20 °C to +60 °C) and verify noise levels stay under 55 dB.

Result: a window that opens faster, silently, and with greater durability, all while reusing the vehicle’s existing control architecture.

6. Resources & Tooling for Smarter Selection

Take advantage of the growing suite of digital tools available to automotive engineers:

- **Motor Data Libraries** – Online repositories (e.g., MotorTech 360, Adafruit Motor Library) categorize motors by torque, speed, and mounting form factor.

- **Simulation Software** – MATLAB/Simulink or Simscape can model torque curves, thermal profiles, and system dynamics before physical prototyping.

- **Rapid Prototyping** – 3D printed mounting brackets and mock‑ups help verify fitment before committing to production molds.

Combining these resources with sound engineering judgment ensures that you pick the right motor and configure it correctly from day one.

Conclusion

Upgrading automotive parts with DC gear motors offers a clear pathway to higher performance, lower maintenance, and improved user satisfaction. By grounding your approach in explicit torque and speed requirements, carefully selecting the motor and gear ratio, and designing robust thermal and mounting solutions, you can transform legacy systems into modern, future‑ready components. As automotive electrification accelerates, the role of efficient, reliable actuators will only grow in importance—making mastery of DC gear motor selection a key strategic advantage for both OEMs and aftermarket innovators alike.

Leave A Reply

Your email address will not be published. Required fiels are marked