The manufacturing sector is currently undergoing a rapid transformation driven by Industry 4.0 principles. Automation, driven by advancements in robotics and control systems, is no longer a future aspiration but a crucial necessity for businesses striving for efficiency, flexibility, and agility. A key element underpinning successful automated production lines is the robust and reliable performance of its components – and among these, gear motors play a pivotal, often underestimated, role. Upgrading existing automated production lines to leverage newer technologies like AI-powered predictive maintenance and increased data analytics, necessitates careful consideration of gear motor selection and configuration. This article explores effective configuration strategies for gear motors, outlining best practices to ensure optimal performance, longevity, and seamless integration into modern automated systems.

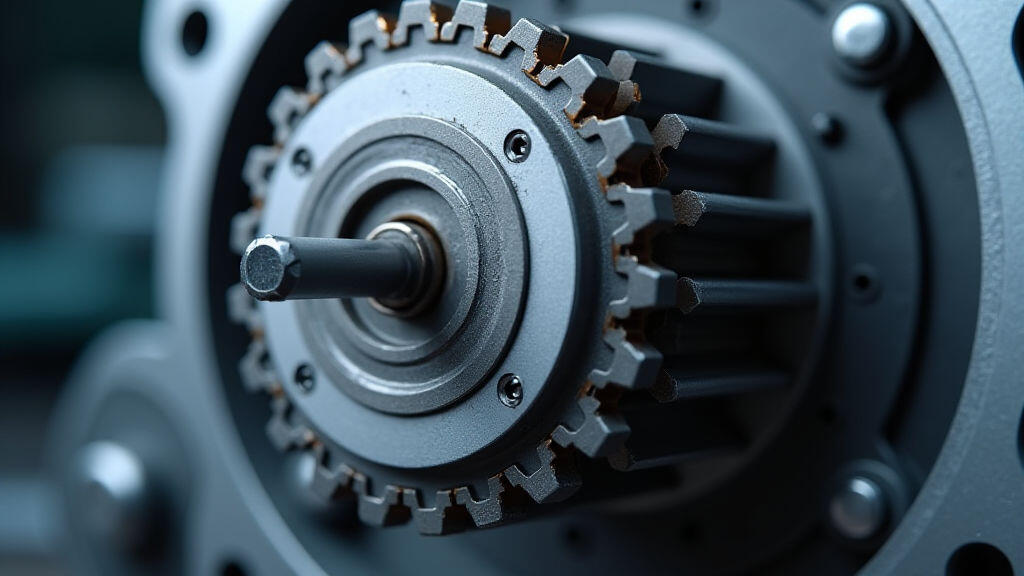

Gear motors are fundamental devices converting rotational motion into torque and speed, crucial for powering a wide array of automated equipment. Think of robotic arms precisely positioning components, conveyor systems moving materials, or automated packaging machines – all heavily reliant on the consistent and accurate power delivery of gear motors. The increasing complexity of modern production processes – demands for higher throughput, greater precision, and more adaptable designs – amplifies the need for sophisticated gear motor solutions.

Beyond simply providing power, gear motors are now integral to intelligent systems. They are increasingly equipped with sensors and integrated control capabilities, enabling data collection on performance metrics like temperature, vibration, and current draw. This data feeds into predictive maintenance algorithms – a cornerstone of Industry 4.0 – allowing for proactive interventions and minimizing costly downtime. The rise of cobots, or collaborative robots, further necessitates gear motors with enhanced safety features, precise control, and adaptable torque characteristics.

Effective gear motor configuration hinges on a multifaceted approach, encompassing mechanical, electrical, and control system considerations. Here's a detailed breakdown of critical factors:

1. Torque and Speed Requirements: The Foundation of Selection

The initial step involves meticulously defining the torque and speed requirements of the application. This isn't a simple estimation; it requires detailed calculations considering load variations, acceleration/deceleration profiles, and potential overload scenarios. Under-sizing the gear motor can lead to premature failure, while over-sizing results in unnecessary energy consumption and increased costs. Simulation software and detailed performance analysis are vital at this stage.

2. Gear Type and Efficiency: Maximizing Performance

Different gear types (spur, helical, bevel, worm) offer varying levels of efficiency, noise levels, and load-carrying capacity. The choice depends on application requirements.

Gear efficiency directly impacts energy consumption and heat generation. Higher efficiency translates to reduced operating costs and extended component life. Manufacturers like MES-Drive offer gear motors with optimized gear designs to minimize energy loss.

3. Motor Type and Power Supply: Electrical Integration

The choice of motor type (AC induction, DC, stepper, servo) impacts performance characteristics like speed control, torque ripple, and responsiveness.

4. Control System Integration: Real-Time Optimization

Seamless integration with the control system is paramount. This involves selecting a gear motor with appropriate communication protocols (e.g., Modbus, EtherCAT) and ensuring compatibility with the existing control architecture.

The current industrial landscape emphasizes minimizing downtime and maximizing asset utilization. Predictive maintenance, fueled by IoT and data analytics, is transforming the approach to equipment management. Gear motors are prime candidates for predictive maintenance strategies.

By incorporating sensors that monitor vibration, temperature, current draw, and other critical parameters, data can be analyzed to detect anomalies indicative of potential failures. AI algorithms can then predict remaining useful life (RUL) and schedule maintenance proactively, avoiding costly unscheduled downtime. This approach reduces maintenance costs, extends gear motor lifespan, and improves overall production efficiency. MES-Drive is actively developing gear motors with integrated IoT capabilities to facilitate seamless data collection and analysis.

Optimizing gear motor configuration is no longer a secondary concern but a critical driver of success in modern automated production lines. By carefully considering torque and speed requirements, gear type and efficiency, motor type and power supply, and control system integration, manufacturers can ensure that gear motors deliver reliable performance, maximize energy efficiency, and contribute to overall system optimization.

The increasing adoption of predictive maintenance, driven by Industry 4.0 trends and events like the global semiconductor shortage impacting supply chains, further elevates the importance of intelligent gear motor solutions. As automation continues to evolve, gear motors will play an increasingly vital role in enabling greater efficiency, flexibility, and resilience in manufacturing operations. Companies like MES-Drive are at the forefront of this evolution, providing innovative gear motor technologies and solutions that empower businesses to thrive in the dynamic world of modern production.

Leave A Reply

Your email address will not be published. Required fiels are marked