Modern food‑processing facilities are constantly seeking ways to enhance speed, reliability, and sustainability. One of the most powerful yet often overlooked upgrades is the gear motor—a compact, efficient drive that empowers machines from mixers to conveyor belts. In this article we demystify what a gear motor really is, why it matters to food‑processing upgrades, and practical configuration strategies that balance performance, cost, and compliance.

A gear motor is a self‑contained unit that merges a motor (usually an electric or hydraulic one) with a gear train. The motor generates rotational motion, and the gears transform that motion by stepping down speed and stepping up torque. This simple combination allows a machine to run at the exact speed required while delivering the force needed to push products along a line, rotate a drum, or compress a log of dough.

In food‑processing terms, gear motors are prized for their:

When a food‑processing line ages, companies face four main challenges:

Upgrading to a high‑quality gear motor addresses each of these points. Modern gear motors come with sealed gearboxes that reduce contamination risk, built‑in variable‑speed controllers that allow fine tuning, and higher efficiency ratings that lower operating costs. The result is a cleaner, faster, and more reliable line that can meet today’s stringent food‑safety standards.

Choosing the right gear motor isn’t just about picking the biggest one. Successful configuration involves a stepwise approach that balances torque, speed, control, and installation constraints.

Calculate the required output torque using the following simple formula:

Torque (Nm) = Load (N) × Radius (m) × Safety Factor

Once you know the torque, determine the desired speed (RPM). For most food‑processing tasks, speeds range between 30–600 RPM, but the exact range depends on the machine (e.g., a dough mixer often operates below 200 RPM).

Gear ratio = Input speed / Output speed. A higher gear ratio boosts torque but reduces output speed. Choose a ratio that meets torque needs without compromising speed. Modern gear motors allow modifiable gear trains or planetary gears, which provide a wide torque range in a compact package.

Internal combustion motors and electric motors each have pros and cons. Electric gear motors typically offer:

Select a motor with a power rating (kW) that exceeds the calculated load by about 20‑30% to accommodate peak demand and future product changes.

Consider gear motors with:

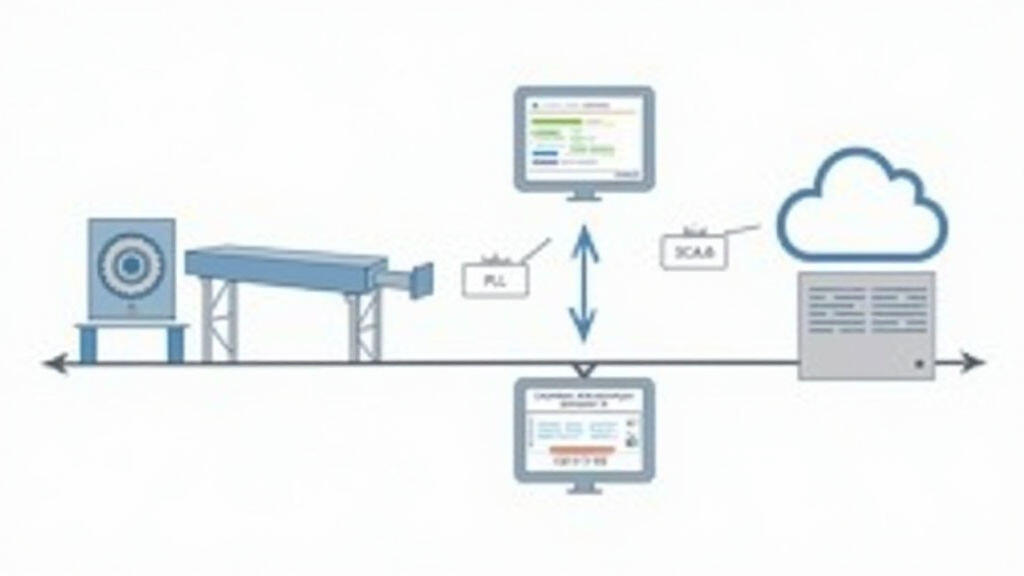

Modern gear motors usually have a built‑in drive controller that communicates via Modbus TCP, EtherNet/IP, or Profibus. Connect this controller to your existing PLC or SCADA system to enable real‑time monitoring and diagnostics. For future scalability, choose motors that support cloud‑based analytics to predict maintenance needs.

Ensure the motor’s footprint fits the existing mechanical frame. Use mounting brackets that can absorb vibrations, especially when the gear motor operates at higher torque. If you’re retrofitting an older machine, consider using a bracket plate that aligns the motor shaft with the existing gear spindle.

Effective configuration also involves a maintenance plan:

Documenting these steps in your plant’s maintenance log allows you to track performance trends and schedule proactive replacements, reducing unscheduled downtime.

A mid‑size bakery upgraded its dough mixing and conveyor system. By replacing an aging 5‑kW motor with a 6‑kW electric gear motor featuring a five‑stage planetary gearbox, the facility achieved:

Operator feedback praised the reduced noise and the ability to program change‑over times directly from the SCADA interface.

We’re witnessing a shift toward “smart” gear motors that embed sensors for torque, temperature, and vibration monitoring. Combined with AI‑driven analytics, these motors can predict when maintenance is required, minimizing waste and shortening equipment life cycles. In the context of food‑processing, this translates to higher product quality, fewer recalls, and lower carbon footprints.

Regulatory bodies increasingly champion energy‑efficient machinery. Gear motors with high efficiency ratings (≥90%) help food‑processing plants meet compliance while cutting operating costs. Moreover, the use of recyclable materials in motor housings is becoming standard, aligning with global sustainability goals.

Upgrading a food‑processing line with the right gear motor is more than a mechanical tweak—it’s a strategic investment in reliability, quality, and future readiness. By carefully defining torque and speed needs, selecting a suitable gear ratio, ensuring food‑safe protective features, and integrating modern control capabilities, operators can transform aging equipment into agile, efficient, and compliant assets. As smart drivers and AI analytics continue to mature, gear motors will play a pivotal role in meeting the rising demands of food‑safety regulations and sustainable production. Embracing these configuration strategies not only protects today’s operations but also positions your plant for the innovations of tomorrow.

Leave A Reply

Your email address will not be published. Required fiels are marked