The automotive industry is undergoing a dramatic transformation, driven by electrification, autonomous driving, and increasingly sophisticated manufacturing processes. This evolution necessitates continuous upgrades to equipment used in automotive parts production, demanding greater precision, efficiency, and reliability. Micro DC gear motors are playing a pivotal role in these upgrades, offering a compact and powerful solution for a wide range of applications, from automated assembly lines to sensor-based quality control systems. However, realizing their full potential requires careful consideration of configuration strategies. This article explores key strategies for effectively utilizing micro DC gear motors in automotive parts equipment upgrades, highlighting considerations for performance, longevity, and cost-effectiveness.

Traditional mechanical systems are being increasingly replaced with automated solutions, boosting productivity and reducing human error. Micro DC gear motors are ideal for these applications due to their:

The trend towards Industry 4.0 and smart manufacturing further accelerates the adoption of these motors. Data-driven insights from connected equipment enabled by micro DC gear motors allow for predictive maintenance, optimizing equipment lifespan and minimizing downtime. Furthermore, advancements in power electronics and motor control algorithms have enhanced the performance and adaptability of these motors, making them a compelling choice for modern automotive manufacturing.

Effective utilization of micro DC gear motors hinges on strategic configuration. Here are several critical aspects to consider:

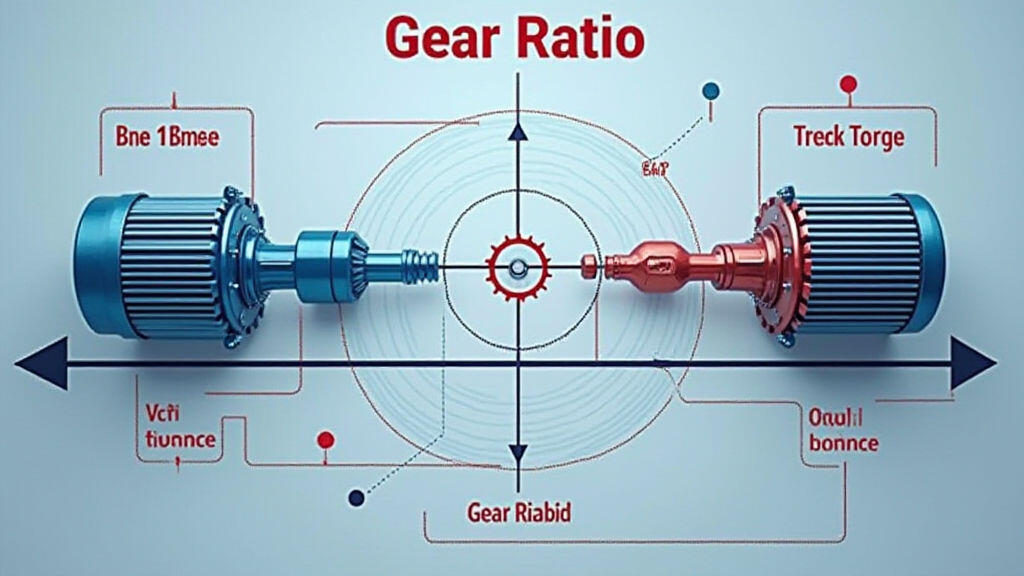

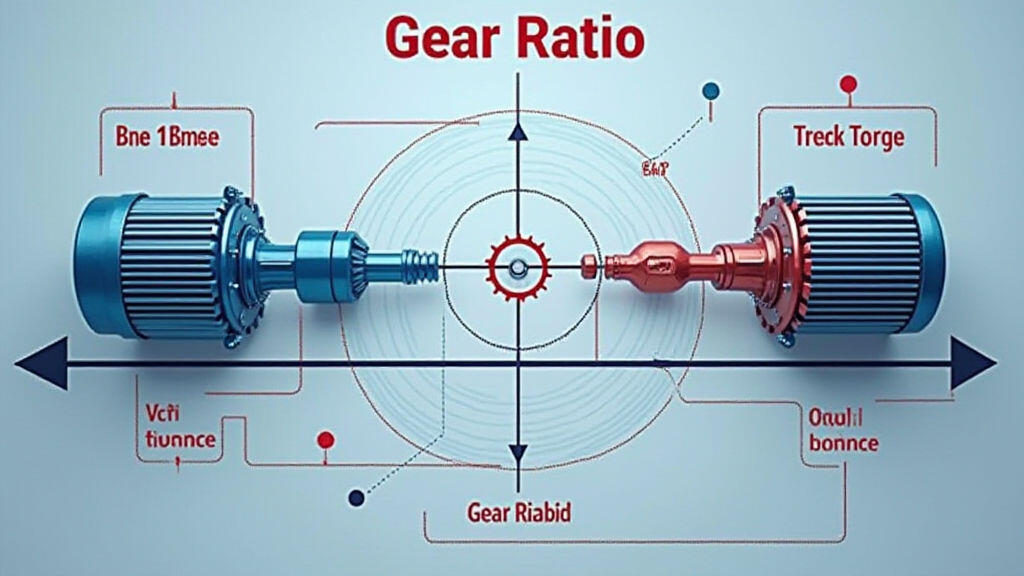

1. Gear Ratio Selection:

The gear ratio is a fundamental parameter that dictates the motor's output torque and speed. Choosing the right ratio is essential for matching the motor's performance to the specific application requirements. For instance, high-precision positioning systems may benefit from lower gear ratios to achieve higher speeds and finer control. Conversely, applications requiring substantial torque, such as opening and closing valves, demand higher gear ratios.

2. Motor Selection (Voltage, Current & Power):

The voltage, current, and power ratings of the motor must be carefully matched to the power supply and the load requirements. Undersizing the motor can lead to performance limitations and premature failure, while oversizing can result in increased costs and reduced efficiency.

3. Cooling Solutions:

Micro DC gear motors, while efficient, can still generate heat under prolonged operation, particularly at high loads. Inadequate cooling can lead to overheating, reduced performance, and ultimately, motor failure.

4. Encoder Integration:

Encoders provide feedback on the motor's position and speed, enabling precise control and closed-loop operation. Integrating encoders is crucial for applications requiring accurate positioning, such as robotic assembly and automated inspection systems.

5. Mounting and Vibration Dampening:

Proper mounting and vibration dampening are essential for minimizing noise, reducing wear and tear, and ensuring the long-term reliability of the motor. Micro DC gear motors are particularly susceptible to vibration due to their small size and high operating speeds.

MES-Drive is a leading provider of high-quality micro DC gear motors for automotive parts equipment upgrades. We offer a comprehensive portfolio of motors, encoders, and custom solutions designed to meet the demanding requirements of modern automotive manufacturing. Our team of engineers provides expert guidance on motor selection and configuration, ensuring optimal performance and reliability. MES-Drive constantly innovate to provide cutting-edge solutions including optimized gear ratios and advanced cooling techniques.

The demand for precision, efficiency, and reliability in automotive manufacturing equipment is only set to increase. Micro DC gear motors are well-positioned to meet these demands, supported by ongoing advancements in motor technology, power electronics, and control algorithms. The convergence of Industry 4.0 and AI technologies will further drive innovation in this field, enabling more intelligent and adaptable motor solutions.

The global automotive industry is currently focused on reducing carbon emissions and adopting sustainable manufacturing practices. Micro DC gear motors, with their high efficiency and low energy consumption, play a vital role in achieving these goals. Moreover, the rise of electric vehicles is creating new opportunities for micro DC gear motors in various applications, including battery management systems and electric vehicle components.

[Insert image showing a futuristic automated assembly line using micro DC gear motors.]

Conclusion

Successfully upgrading automotive parts equipment requires a strategic approach to motor selection and configuration. By carefully considering gear ratio, motor power, cooling solutions, encoder integration, and vibration dampening, manufacturers can maximize the performance, longevity, and cost-effectiveness of micro DC gear motors. MES-Drive is committed to providing innovative solutions and expert support to help our customers achieve their manufacturing goals. As the automotive industry continues its transformative journey toward electrification, automation, and sustainability, micro DC gear motors will remain a critical enabler of progress. The increasing integration of AI for motor control and predictive maintenance represents a significant opportunity to further enhance the capabilities and value of these motors, paving the way for a smarter, more efficient, and more sustainable automotive future.

Leave A Reply

Your email address will not be published. Required fiels are marked