The robotics industry is experiencing explosive growth, fueled by advancements in AI, automation, and the increasing demand for intelligent solutions across various sectors – from manufacturing and logistics to healthcare and even domestic applications. At the heart of every robot lies its motor system, and choosing the right motor is a critical decision that directly impacts performance, efficiency, and overall project success. A fundamental choice robotics enterprises face is between gear motors and servo motors. But with a plethora of options available, it’s easy to get lost in the technical details. This article will break down the key differences, common mistakes made during the purchasing process, and provide practical solutions to help your robotics enterprise make informed decisions. We'll also touch on how emerging trends like edge computing and collaborative robotics are influencing motor selection.

At its core, the distinction between gear motors and servo motors lies in their fundamental purpose and control mechanisms.

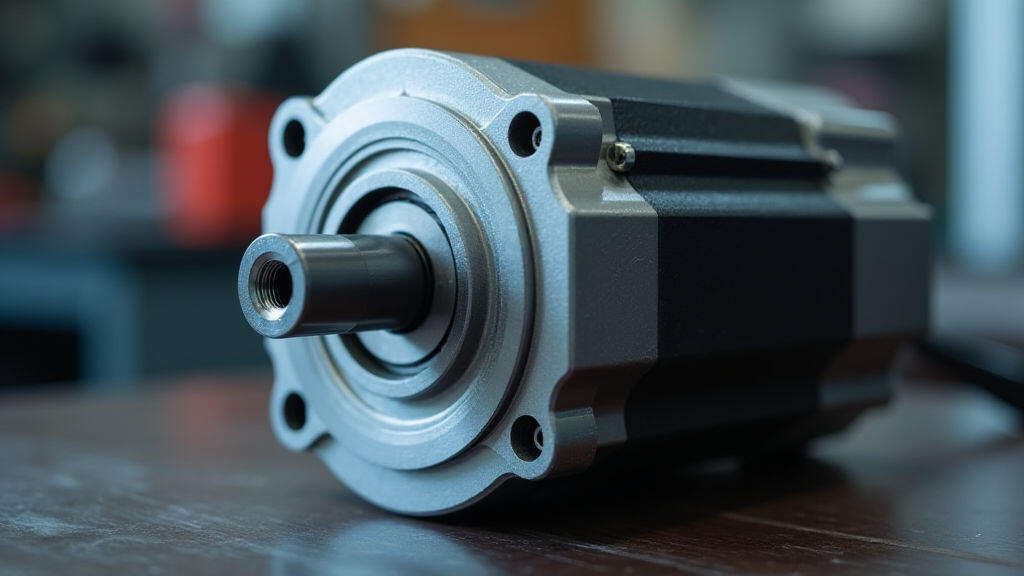

Gear Motors: These are essentially electric motors with a gearbox attached. The gearbox reduces the motor's high speed and increases its torque, making them ideal for applications requiring high power and moderate speed. Think of a car engine – it generates power, and the transmission (gearbox) adapts it to the needs of the wheels. Gear motors are generally more cost-effective than servo motors.

Servo Motors: These are closed-loop control systems, meaning they use feedback to precisely control their position, velocity, and acceleration. They consist of a motor, a position sensor (like an encoder), and a control circuit. The control circuit continuously compares the desired position with the actual position, adjusting the motor’s power to minimize the error. This feedback loop enables highly accurate and repeatable movements.

| Feature | Gear Motors | Servo Motors | |---|---|---| | Control | Open-loop (less precise) | Closed-loop (highly precise) | | Torque | High | Variable, dependent on control | | Speed | Moderate | Variable, often high | | Position Feedback | No | Yes (using encoders/sensors) | | Complexity | Simpler | More complex | | Cost | Generally lower | Generally higher | | Efficiency | Can be less efficient due to gearbox losses | Can be more efficient, especially with advanced control algorithms | | Applications | Conveyors, power tools, simple robotic arms | Precision robotics, CNC machines, autonomous vehicles |

Several common pitfalls can lead to suboptimal motor choices:

Ignoring Torque Requirements: This is perhaps the most critical mistake. Many companies underestimate the torque needed for their application. A motor might be physically capable of delivering a certain torque, but if it’s not sufficient to overcome the load (weight, friction, acceleration), the robot's performance will suffer. Solution: Perform a thorough torque analysis of the robot's application. Consider static torque (holding a position), dynamic torque (accelerating and decelerating), and peak torque (handling sudden loads). Utilize online torque calculators or consult with motor vendors.

Neglecting Speed and Accuracy Needs: Choosing a gear motor when precision is paramount is a common error. If the robot requires precise positioning or velocity control, a servo motor is the clear choice. Solution: Clearly define the required speed, accuracy, and repeatability of the robot's movements. Consider the application carefully; does it require jerky motions or smooth, controlled movements?

Underestimating the Importance of Feedback: Open-loop control (gear motors) is suitable for simple, repetitive tasks where precise positioning is not essential. For more complex movements, a closed-loop servo system is crucial. Solution: Determine if position feedback is necessary. If the robot needs to accurately reach specific points or follow complex trajectories, a servo motor with an encoder is essential.

Focusing Solely on Initial Cost: While price is a factor, it shouldn't be the only one. A cheaper gear motor might require frequent maintenance or result in lower performance over time. Consider the Total Cost of Ownership (TCO), including maintenance, energy consumption, and lifespan. Solution: Request detailed cost breakdowns from multiple vendors, and compare TCO figures rather than just initial price.

Ignoring Environmental Factors: Operating conditions (temperature, humidity, dust) can significantly impact motor performance and lifespan. Solution: Choose motors rated for the specific environmental conditions of the robot's operating environment. Look for sealed or encapsulated motors for harsh environments.

Several emerging trends are influencing motor selection in robotics:

MES-Drive understands the complexities of motor selection for robotics applications. We offer a comprehensive range of high-quality gear motors and servo motors to meet diverse needs. Our team of experts can help you navigate the motor maze and choose the right solution for your project. We provide detailed technical specifications, application support, and customized motor solutions. We also offer integration services, ensuring seamless motor integration into your robotic system.

Choosing the right motor—whether a gear motor for high torque or a servo motor for precision—is a pivotal decision for any robotics enterprise. Understanding the core differences, avoiding common pitfalls, and considering emerging trends are key to ensuring the success of your robotic projects. As robotics continues its rapid evolution, driven by trends like AI and edge computing, the demand for high-performance and reliable motor solutions will only increase. MES-Drive is committed to providing the innovative motor technologies and expert support you need to power the future of robotics. Staying abreast of these developments and making informed motor choices will be instrumental in maintaining a competitive edge in this dynamic and rapidly growing industry.

Leave A Reply

Your email address will not be published. Required fiels are marked